An organic electroluminescent device with a barrier layer

An electroluminescent device and barrier layer technology, applied in the direction of electro-solid devices, electrical components, circuits, etc., can solve the problems of triplet energy level mismatch and low luminous efficiency, achieve excellent luminous efficiency, ensure luminous efficiency, and easily selected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

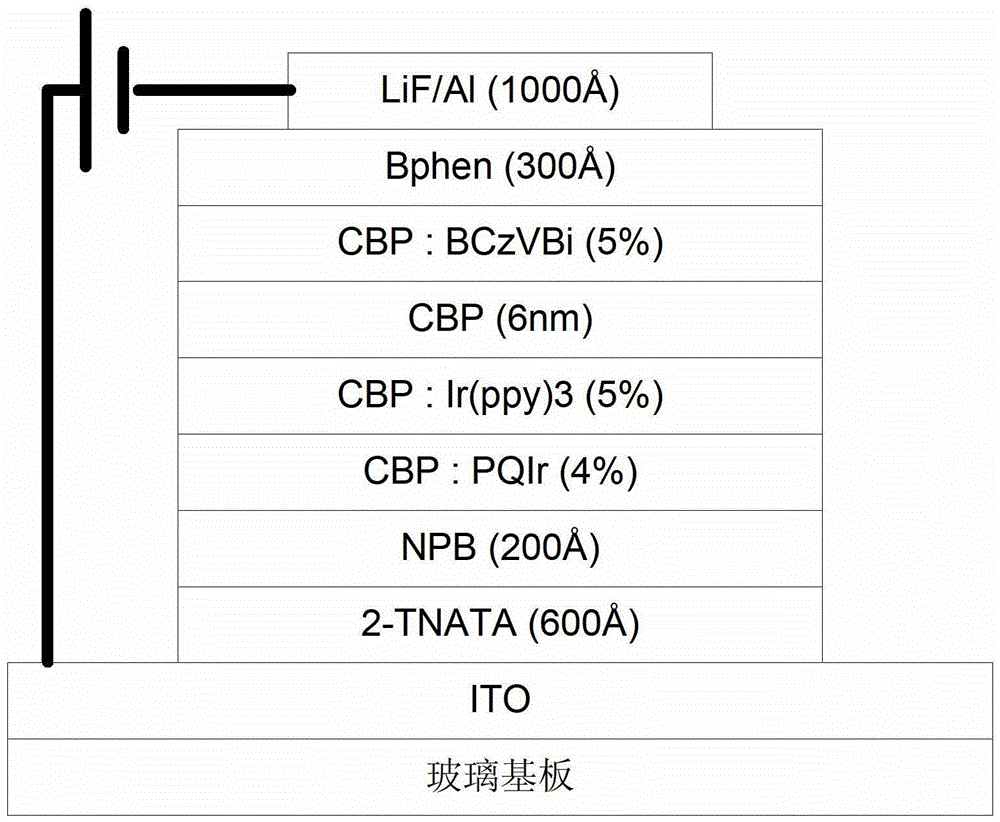

[0116] Organic electroluminescent device structure:

[0117] ITO / 2-TNATA(60nm) / NPB(20nm) / EMLR / EMLG-1 / Spacer(10nm) / EML-B / BPhen(30nm) / LiF(3nm) / Al(150nm)

[0118] like image 3 As shown, it is a cross-sectional view of the structure of Embodiment 1 of the present invention, which includes a substrate 10, an anode layer 20, a hole injection layer 30, a hole transport layer 40, a red phosphorescent light-emitting layer 50, a green phosphorescent light-emitting layer 60, and a blocking layer. 70 , blue fluorescent light-emitting layer 80 , electron transport layer 90 , cathode layer 100 .

[0119] The preparation method of the organic light-emitting device is as follows:

[0120] ①Using detergent ultrasonic and deionized water ultrasonic methods to clean the ITO glass substrate that has been etched with a fixed pattern, and place it to dry under an infrared lamp.

[0121] ②Place the above-treated glass substrate in a vacuum chamber and evacuate to 1×10 -5 Pa, a hole injection la...

Embodiment 2

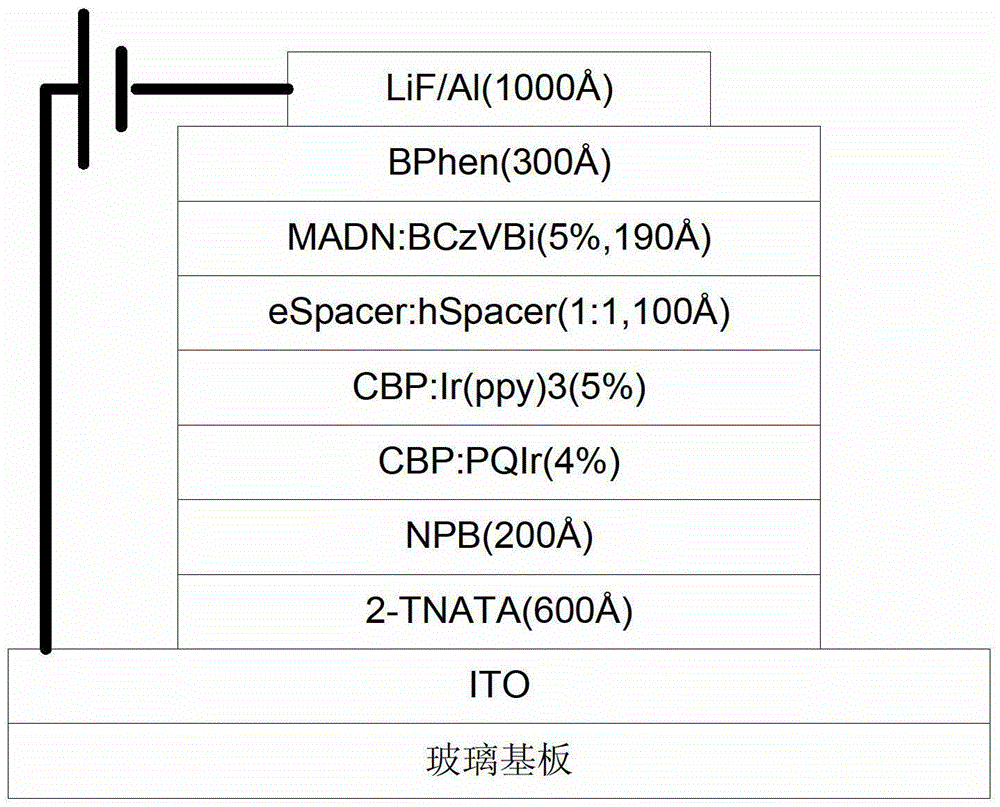

[0132] Organic electroluminescent device structure:

[0133] ITO / 2-TNATA(60nm) / NPB(20nm) / EML-R / EMLG-2 / Spacer(10nm) / EML-B / BPhen(30nm) / LiF(3nm) / Al(150nm)

[0134] The preparation method is the same as that in Example 1, except that the green phosphorescent light-emitting layer material in step ④ is replaced.

Embodiment 3

[0136] Organic electroluminescent device structure:

[0137] ITO / 2-TNATA(60nm) / NPB(20nm) / EML-B / Spacer(10nm) / EMLG-1 / EMLR / BPhen(30nm) / LiF(3nm) / Al(150nm)

[0138] The preparation method is the same as that in Example 1, except that step ④ is implemented after step ⑥, and the evaporation sequence of the green phosphorescent light-emitting layer is reversed with that of the red phosphorescent light-emitting layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com