Flyconnector for LED module board

A technology of LED modules and connectors, which is applied in the direction of connection, fixed connection, and parts of connection devices, etc., to achieve the effect of excellent assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Next, a configuration example of a connector for an LED module substrate (hereinafter simply referred to as a “connector”) 1 according to the present invention will be described with reference to the drawings.

[0053] In the following embodiments, although various limitations are made on constituent elements, types, combinations, shapes, relative arrangements, etc., these are merely examples, and the present invention is not limited thereto.

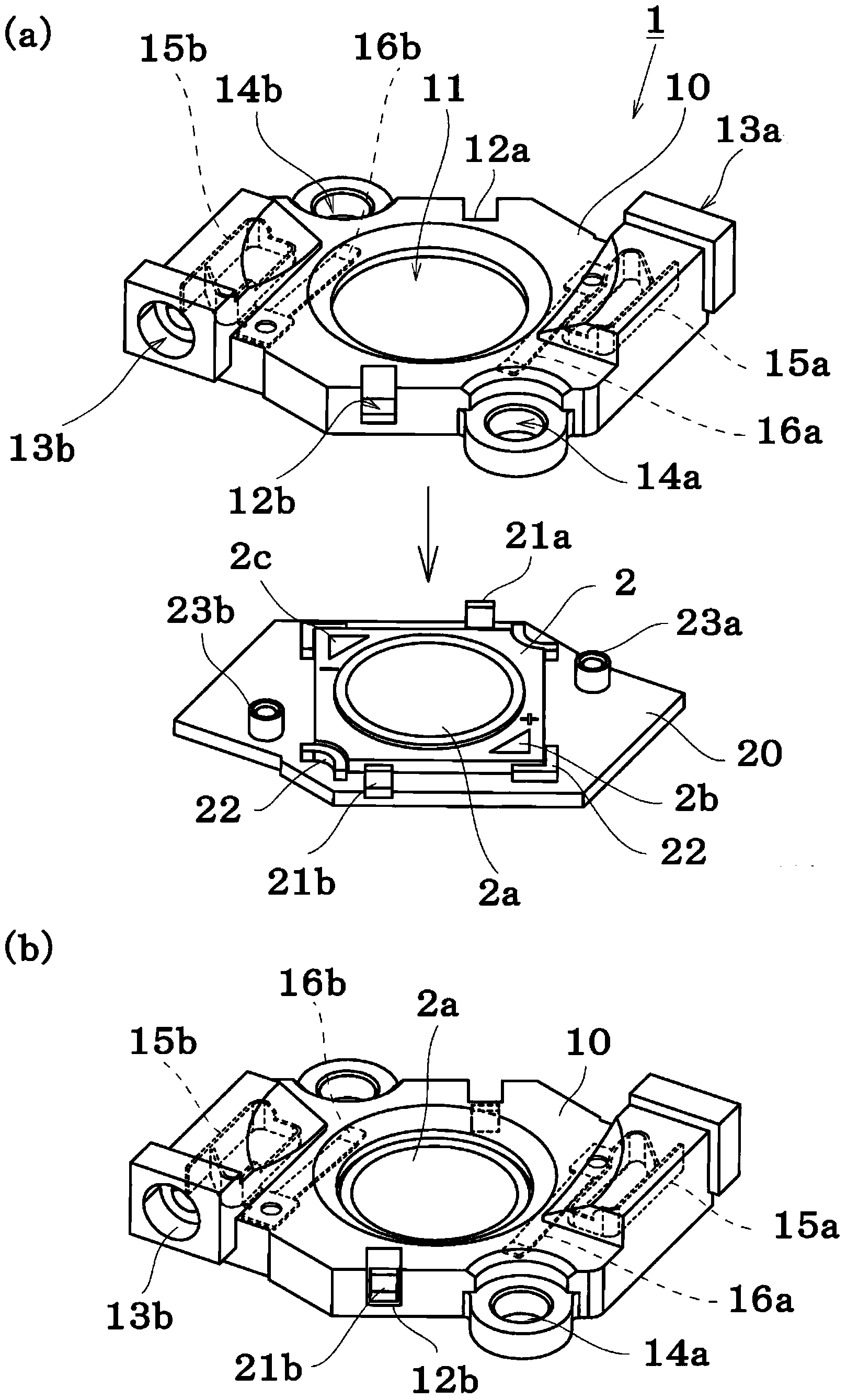

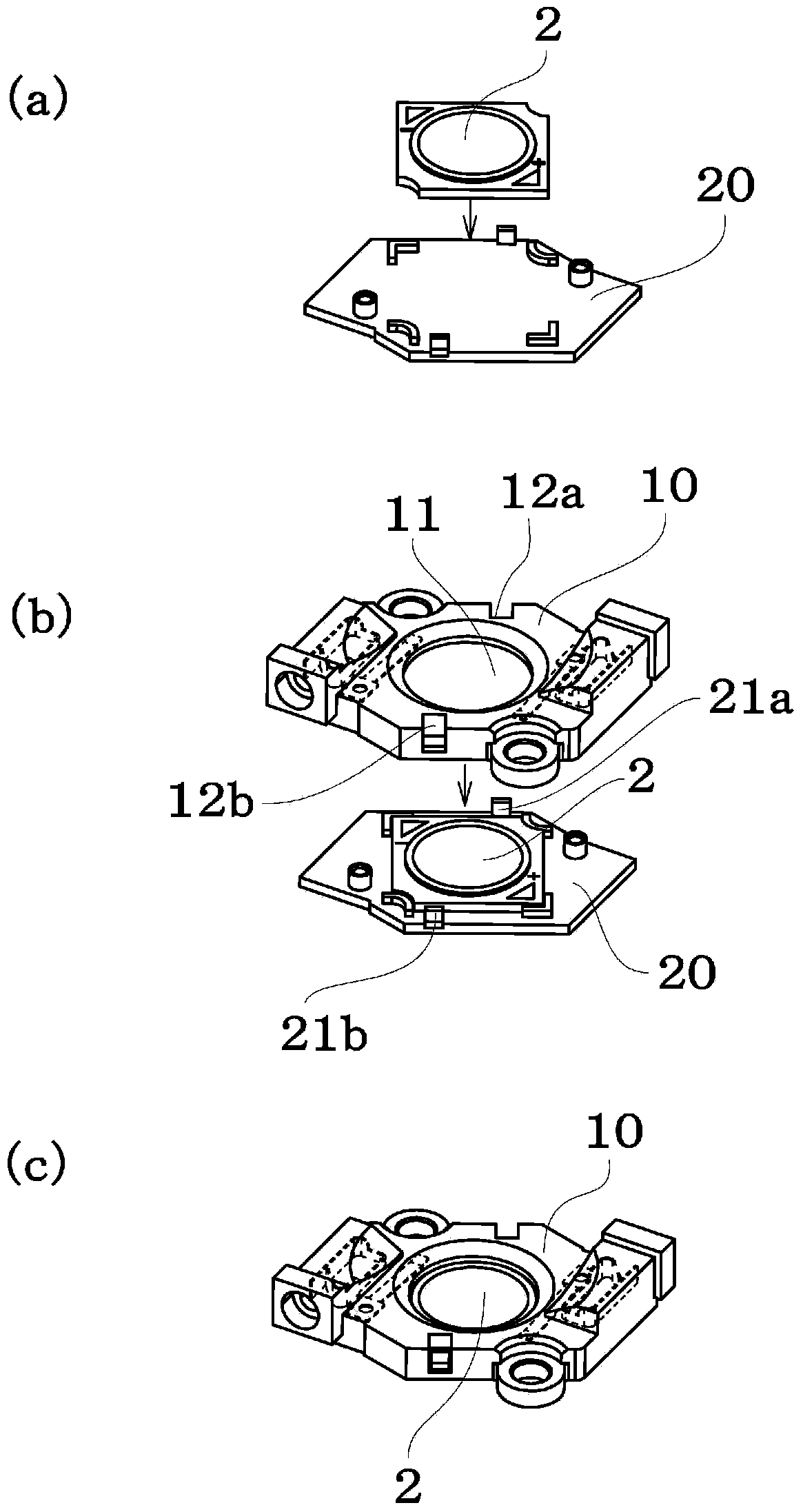

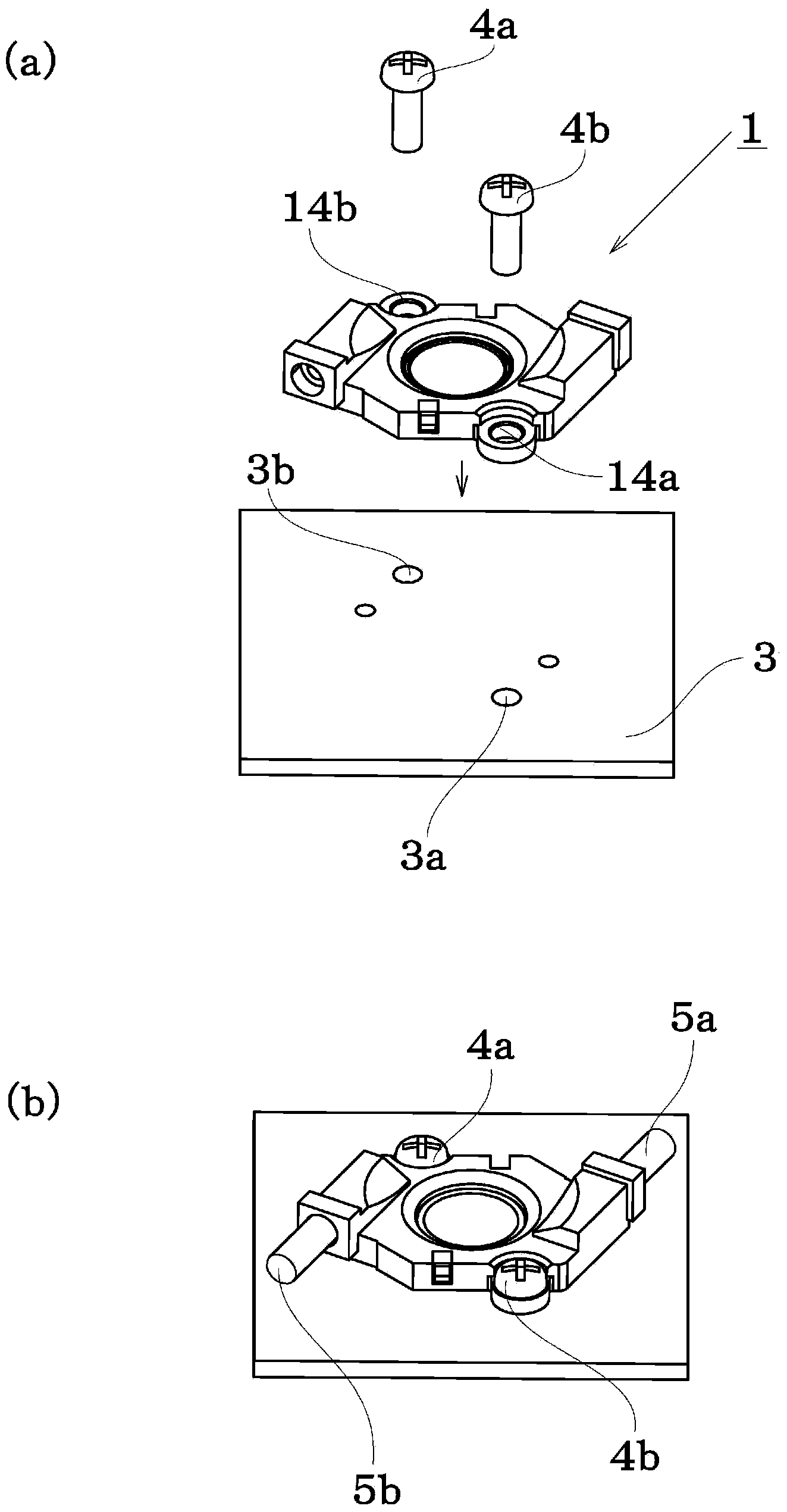

[0054] figure 1 represents the first embodiment, figure 2 Indicates the assembly sequence.

[0055] The lower cover member 20 is molded from a thermally conductive insulating resin material having a thermal conductivity (steady state method) of 1.5 W / mK or higher, preferably 5.0 W / mK or higher, and a dielectric breakdown voltage of Insulation above 1KV.

[0056] In an embodiment of the present invention, at least the portion of the lower cover member 20 located on the bottom surface of the LED module substrate is formed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com