Separation method for removing styrene from ethylbenzene-dehydrogenation tail gas and recovering hydrogen

A technology for dehydrogenation of ethylbenzene and catalytic dehydrogenation of ethylbenzene, applied in the petrochemical field, can solve the problems of reducing the gas permeation rate, unfavorable regeneration of adsorbents, affecting the lubrication of rotating parts, etc., to achieve separation efficiency and equipment service life guarantee, The effect of reducing service life and separation efficiency and ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

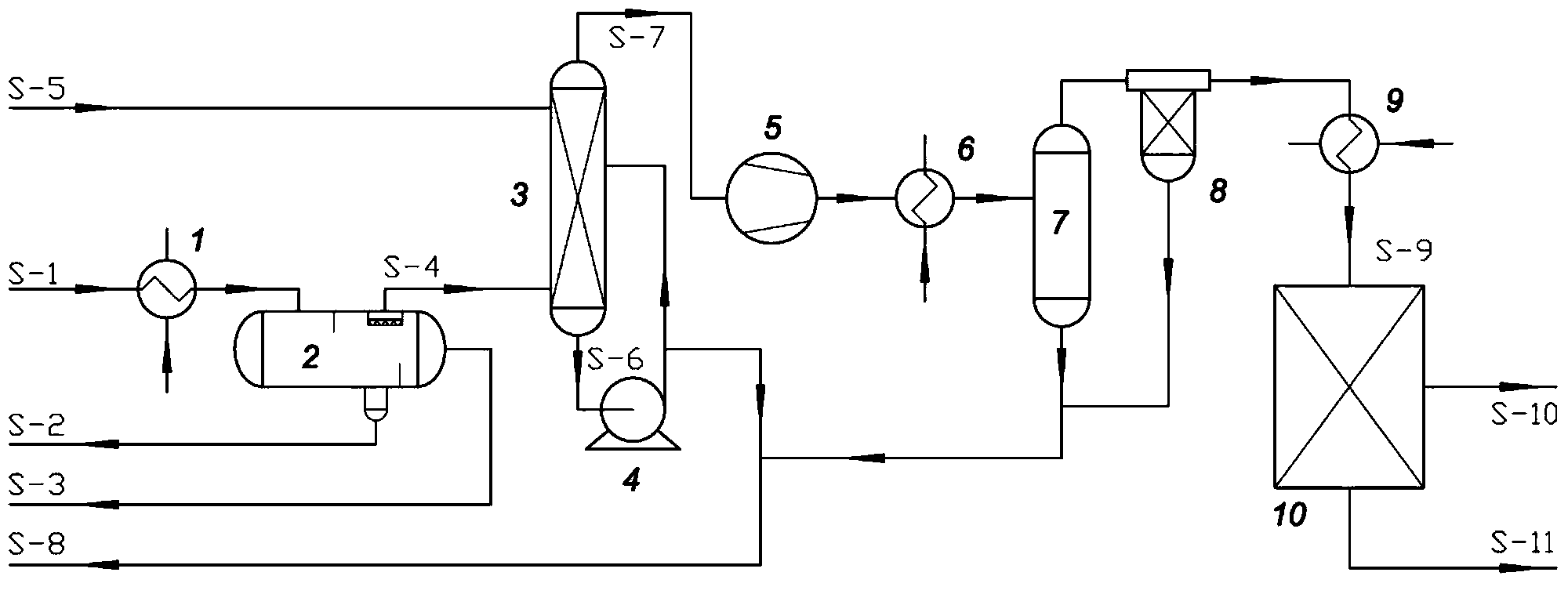

[0031] Example 1 Regarding the ethylbenzene dehydrogenation tail gas produced in a 100,000-ton / year styrene production device, the method for deep styrene removal of the present invention is used for pretreatment and compression, and then a pressure swing adsorption separation device is used to separate and purify hydrogen. Such as figure 1 As shown, the ethylbenzene dehydrogenation tail gas S-1 (3406Nm3 / h, 0.02MPag, 40°) produced by the styrene production unit is input into the first heat exchanger 1 and cooled to 20°C, and then enters the three-phase separation tank 2 Among them, the condensed water S-2 and crude styrene S-3 are extracted from the bottom and middle of the three-phase separation tank 2 respectively, and the uncondensed ethylbenzene dehydrogenation tail gas S-4 is extracted from the top of the three-phase separation tank 2. It enters from the bottom of the circulating absorption tower 3 and contacts with the ethylbenzene S-5 (2.5t / h, 20°C) input from the top of ...

Embodiment 2

[0036] Example 2 Regarding the ethylbenzene dehydrogenation tail gas produced in a 100,000-ton / year styrene production device, the method for deep styrene removal of the present invention is used for pretreatment and compression, and then a hydrogen membrane separation device is used to separate and purify hydrogen.

[0037] Such as figure 1 As shown, the ethylbenzene dehydrogenation tail gas S-1 (3406Nm3 / h, 0.02MPag, 40°) produced by the styrene production unit is input into the first heat exchanger 1 and cooled to 20°C, and then enters the three-phase separation tank 2 Among them, the condensed water S-2 and crude styrene S-3 are extracted from the bottom and middle of the three-phase separation tank 2 respectively, and the uncondensed ethylbenzene dehydrogenation tail gas S-4 is extracted from the top of the three-phase separation tank 2. It enters from the bottom of the circulating absorption tower 3, and contacts with the ethylbenzene S-5 (4.0t / h, 20℃) input from the top of t...

Embodiment 3

[0042] Example 3 Regarding the ethylbenzene dehydrogenation tail gas produced by a 100,000-ton / year styrene production device, the method for deep removal of styrene of the present invention is used for pretreatment and compression, and then a pressure swing adsorption coupled hydrogen membrane separation device is used for separation and purification hydrogen.

[0043] Such as figure 1 As shown, the ethylbenzene dehydrogenation tail gas S-1 (3406Nm3 / h, 0.02MPag, 40°) produced by the styrene production unit is input into the first heat exchanger 1 and cooled to 20°C, and then enters the three-phase separation tank 2 Among them, the condensed water S-2 and crude styrene S-3 are extracted from the bottom and middle of the three-phase separation tank 2 respectively, and the uncondensed ethylbenzene dehydrogenation tail gas S-4 is extracted from the top of the three-phase separation tank 2. It enters from the bottom of the circulating absorption tower 3, and contacts with the ethylbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com