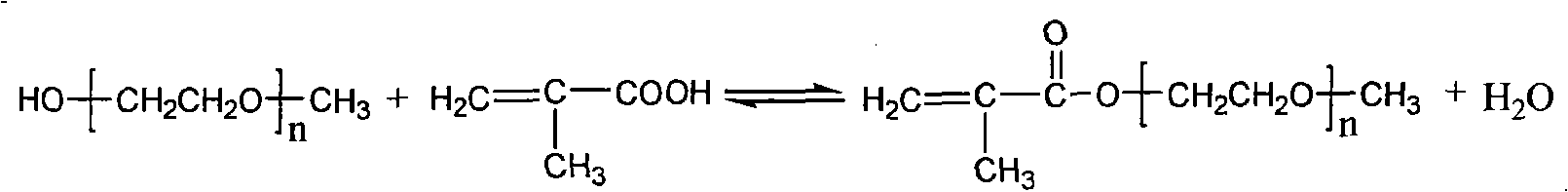

Controllable method for preparing methoxy polyethylene glycol methacrylate-styrene polymer under condition of high vacuum degree

A technology of polyethylene glycol methacrylate and methoxypolyethylene glycol, which is applied in the direction of organic chemistry, can solve the problems of difficult extraction, difficult catalyst recovery, limited entrainment effect, etc., and achieves mild reaction conditions and high reaction temperature. Low, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 30.2000g of methoxypolyethylene glycol (the degree of polymerization n is 13) into the reaction kettle, add catalyst 4-(dimethylamino)pyridine 1.0351g under stirring, heat to dissolve, weigh 0.0086g of polymerization inhibitor and dissolve in 4.3045 In 1 g of methacrylic acid, connect constant pressure drop liquid and controllable vacuuming device, control the vacuum at 0.095MPa, raise the temperature to 63°C, add methacrylic acid dropwise within 3 hours, react for 5 hours, and cool down to obtain methoxy Polyethylene glycol methacrylate.

Embodiment 2

[0021] Add 50.3000g of methoxypolyethylene glycol (the degree of polymerization n is 45) in the reaction kettle, add the catalyst 4-(dimethylamino)pyridine 2.1239g under stirring, heat to dissolve, weigh 0.0084g of polymerization inhibitor and dissolve in 2.7979 In 1 g of methacrylic acid, connect constant pressure drop liquid and controllable vacuuming device, control the vacuum at 0.097MPa, raise the temperature to 50°C, add methacrylic acid dropwise within 2 hours, react for 5.5 hours, and cool down to obtain methoxy Polyethylene glycol methacrylate.

Embodiment 3

[0023] Add 110.8000g of methoxypolyethylene glycol (polymerization degree n is 100) in the reaction kettle, add catalyst 4-(dimethylamino)pyridine 5.7014g under stirring, heat to dissolve, weigh 0.0129g of polymerization inhibitor and dissolve in 3.2284 In 1 g of methacrylic acid, connect constant pressure drop liquid and controllable vacuuming device, control the vacuum at 0.099MPa, raise the temperature to 30°C, add methacrylic acid dropwise within 2.5 hours, react for 6 hours, and cool down to obtain methoxy Polyethylene glycol methacrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com