Hourglass type pore channel nuclear pore filtering film and preparation method thereof

A nuclear pore filter membrane, hourglass type technology, applied in the field of nuclear pore filter membrane preparation, can solve the problem of low filtration speed of the nuclear pore filter membrane, affecting the use conditions and service life of the nuclear pore filter membrane, easy blockage of the nuclear pore filter membrane, etc. problem, to achieve the effect of being conducive to repeated washing, improving anti-pollution ability and improving pollution-holding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

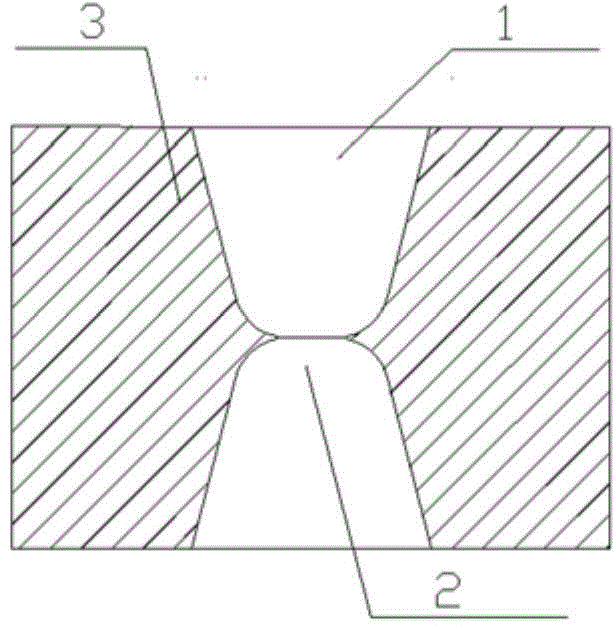

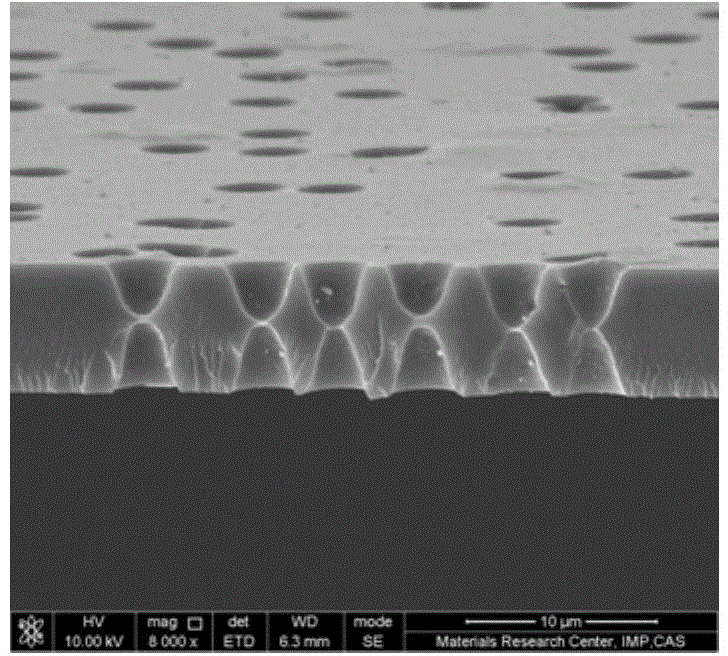

[0021] Example 1: see figure 1 , an hourglass-shaped pore nuclear pore filter membrane, which includes nuclear pores formed by heavy ion irradiation etching on the polymeric film 3, and the nuclear pore channel section is two cups connected by inner holes at the bottom of the cup, which is hourglass-shaped; The film is PET with a thickness of 10 μm. The nuclear pore channel is an hourglass shape, the diameter of the outer hole 1 is 4 μm, and the diameter of the inner hole 2 is 2 μm.

Embodiment 2

[0022] Embodiment 2: An hourglass-shaped pore nuclear pore filter membrane, which includes nuclear pores irradiated with heavy ions on a polymeric film 3, the film is PET, and the thickness is 30 μm. The cross-section of the nuclear pore is two cups connected by the inner hole at the bottom of the cup, which is hourglass-shaped. The diameter of the outer hole 1 is 3 μm, and the diameter of the inner hole 2 is 1 μm.

Embodiment 3

[0023] Embodiment 3: An hourglass-shaped pore nuclear pore filter membrane, which includes nuclear pores irradiated with heavy ions on a polymeric film 3, the film is PC, and the thickness is 10 μm. The cross-section of the nuclear pore is two cups connected by the inner hole at the bottom of the cup, showing an hourglass shape; the diameter of the outer hole 1 is 3 μm, and the diameter of the inner hole 2 is 0.4 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com