Micro-power sewage biological rapid filtration system and technology using the same

A sewage biological and micro-dynamic technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Changes, sewage treatment and discharge management problems such as inconvenience, to achieve the effect of beautifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below we combine the accompanying drawings and specific examples to further describe this microdynamic sewage biological rapid filtration system and process in detail.

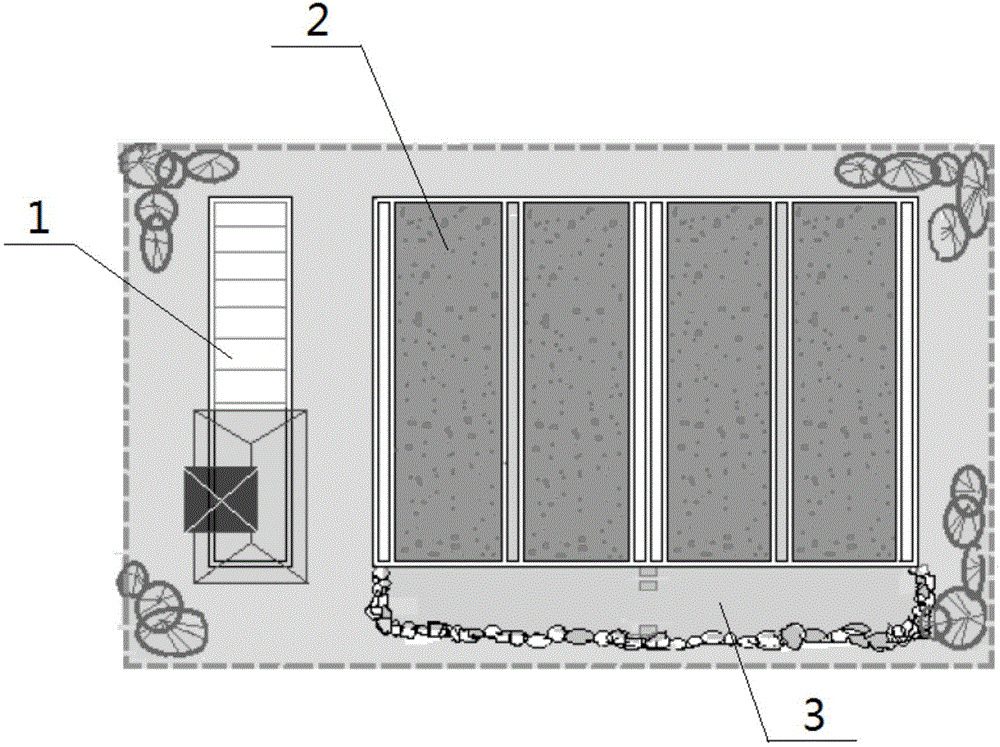

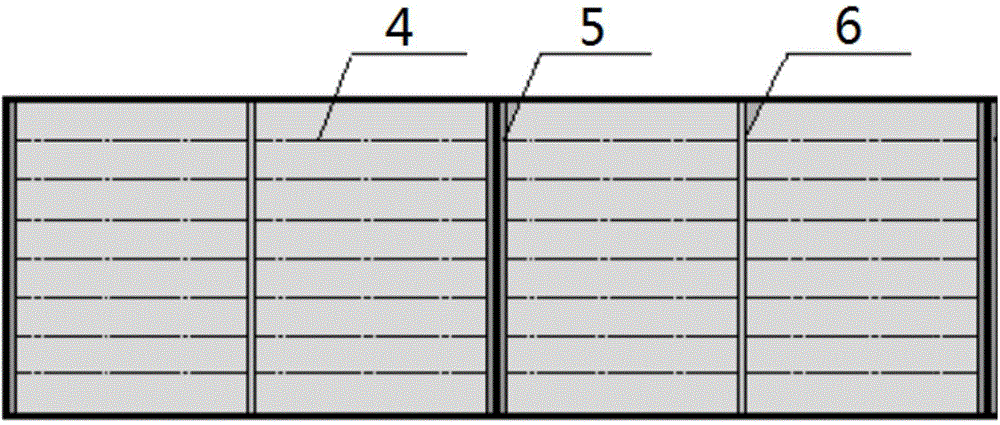

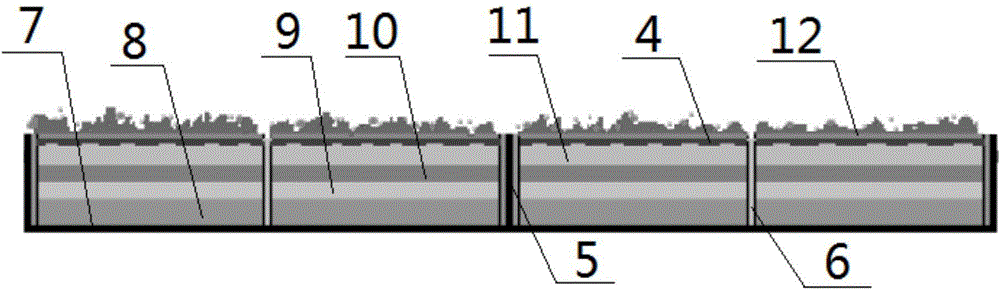

[0047] This microdynamic sewage biological fast filtration system includes a pretreatment pool 1, a program-controlled fast filter field 2 and a disinfection reaction pool 3 connected in sequence, and is characterized in that: the program-controlled fast filter field 2 includes the main body of the first fast filter field and The main body of the second quick filter field, the water inlet and air intake mechanism arranged at the center of the main body of the quick filter field, and the return mechanism symmetrically arranged on both sides of the main body of the quick filter field; Interconnected perforated return pipes 4; the main body of the quick filter field is filled with multiple functional filter material layers, and an anti-seepage film 7 is laid on the inner wall of the main body of the quick f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com