Water heater noise self-adaptive control method and water heater

A control method, water heater technology, applied in the direction of combustion method, controlled combustion, fluid heater, etc., to achieve the effect of precise wind pressure value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

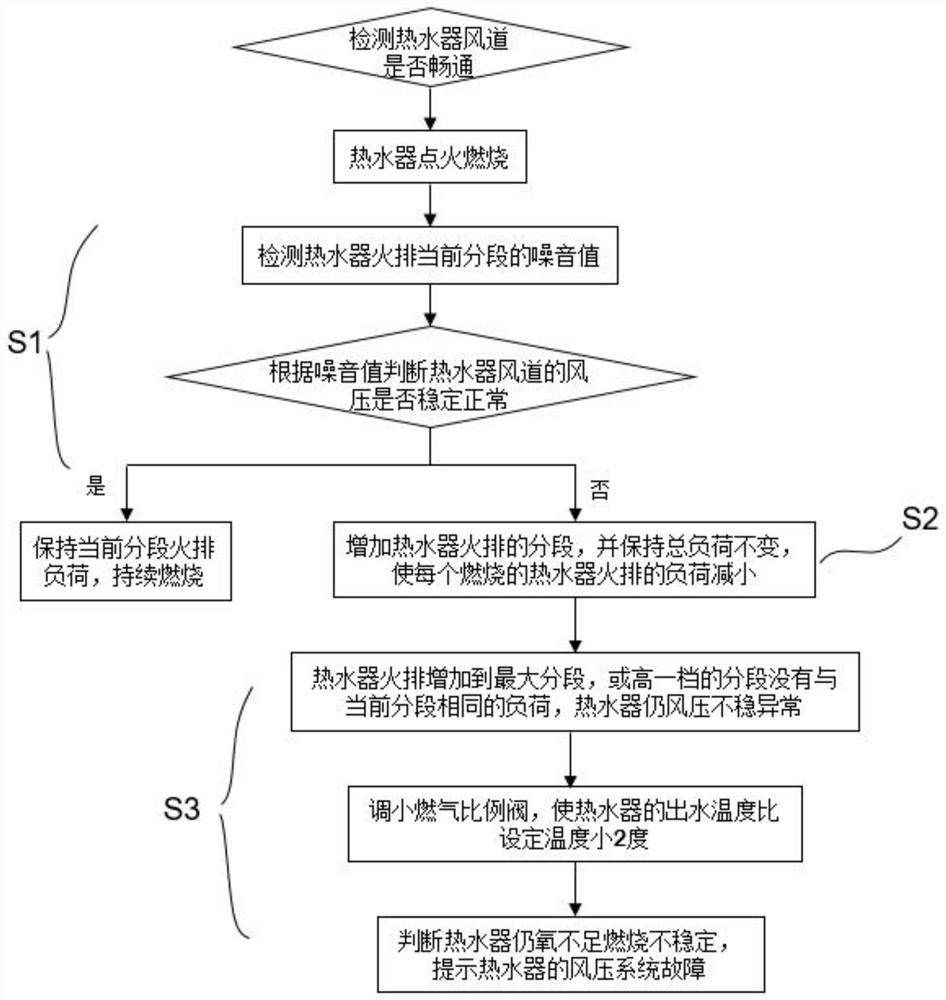

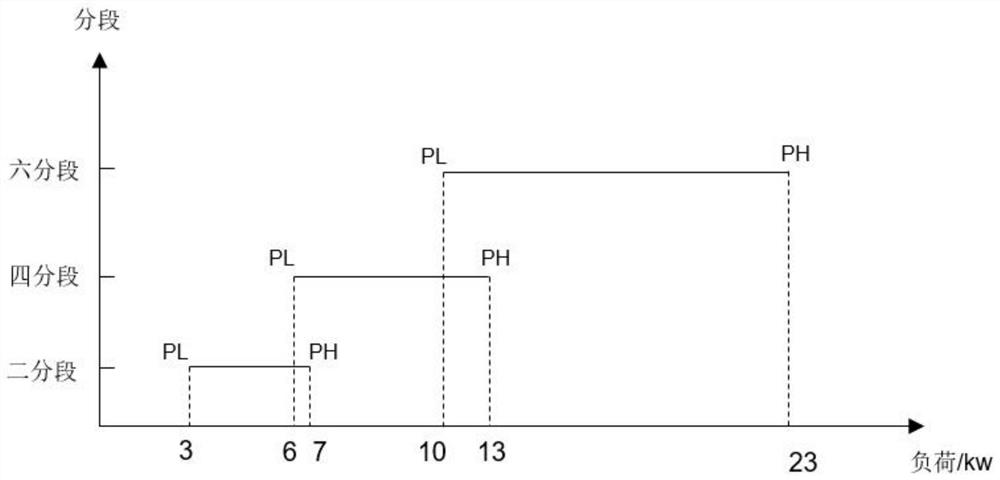

[0040]The first embodiment of the present invention provides a noise adaptive control method of a water heater, such asfigure 1 with2As shown, the water heater fire row is set with multiple stages, and the method includes the following steps:

[0041]S1. Detect the noise value of the current section of the water heater fire row, and judge whether the wind pressure of the water heater duct is stable and normal according to the noise value; if yes, keep the current fire row section load, if not, go to step S2;

[0042]S2, increase the segment of the water heater fire row, and keep the total load unchanged, so that the load of each burning water heater fire row is reduced, and then repeat step S1;

[0043]Through the above method, the noise value of the water heater is detected and matched with the load of the water heater fire exhaust. It is judged whether the air pressure of the water heater is stable and normal, and whether the oxygen supply is sufficient and the combustion is stable. If the...

Embodiment 2

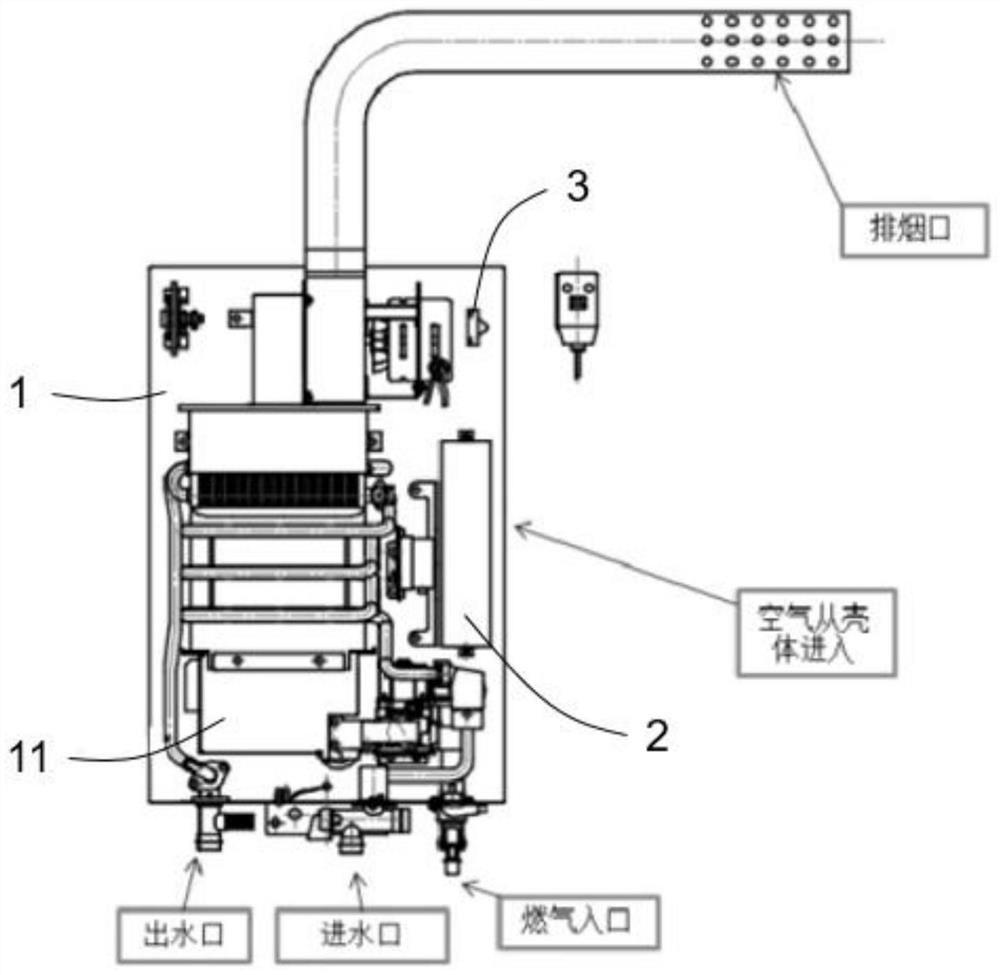

[0067]The second embodiment of the present invention provides a water heater, such asimage 3As shown, it includes a water heater body 1, a noise detection unit 2 and a controller. The controller is arranged on the water heater body 1, and the noise detection unit 2 is arranged on the side of the combustion chamber 11 of the water heater body 1. The controller is based on the noise detection unit 2 The detection value controls the working condition of the fire exhaust in the combustion chamber 11.

[0068]With the above structure, the noise detection unit 2 detects the noise during the combustion of the fire exhaust, and the controller controls the working condition of the fire exhaust according to the self-adaptive control method for noise of the water heater provided in the first embodiment. The water heater can burn stably.

[0069]This embodiment also includes a wind pressure switch 3, which is installed on the water heater body 1, and the controller controls the operation of the combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com