Recycling method for phthalic anhydride residues

A technology of residue and phthalic anhydride, which is applied in the field of recycling and utilization of phthalic anhydride residue to achieve high recovery rate and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the present invention is further described:

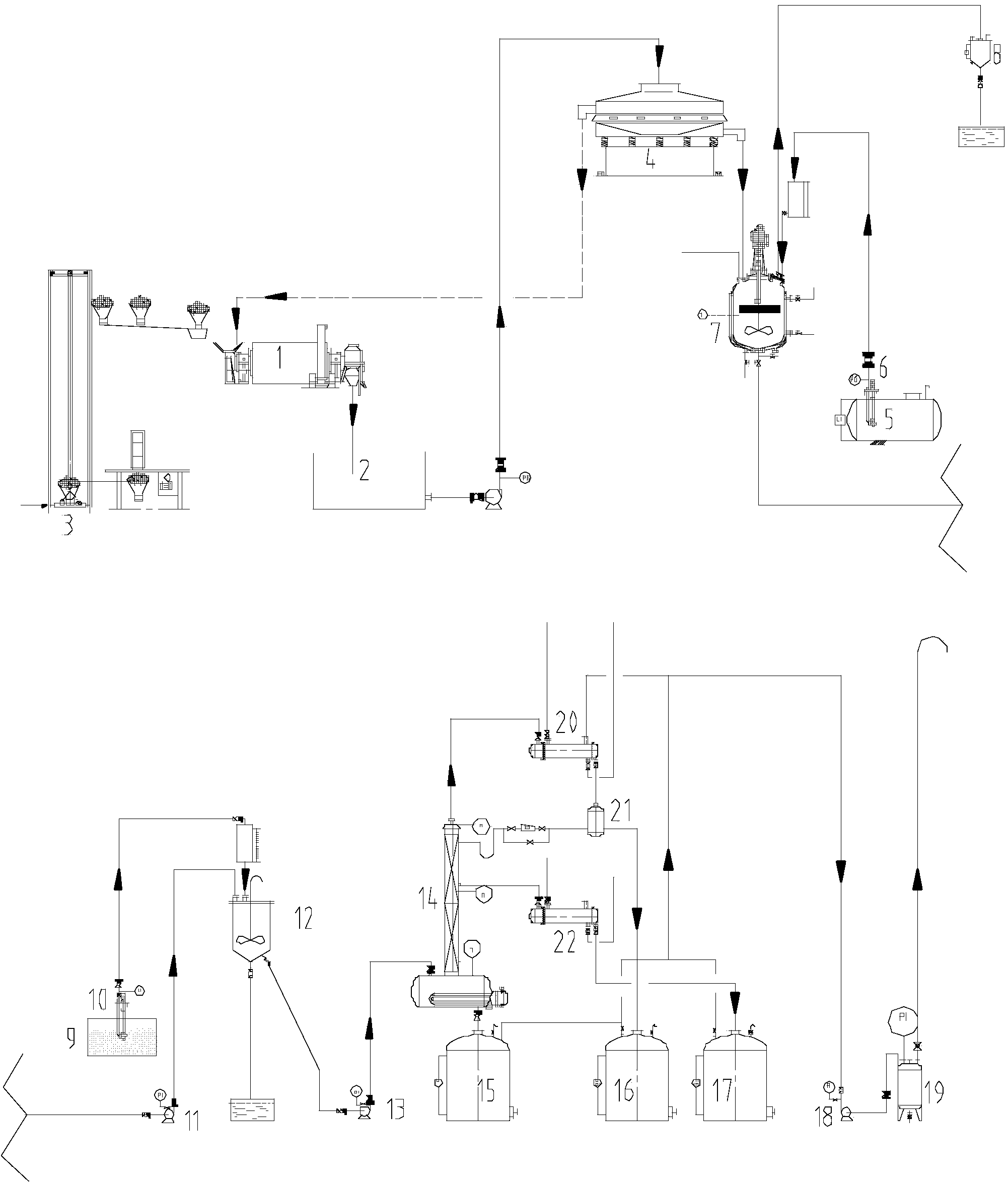

[0013] Such as figure 1 Shown:

[0014] Phthalic anhydride residue recovery di-n-butyl phthalate concrete steps are as follows:

[0015] 1) Grinding and screening of phthalic anhydride residues: After the phthalic anhydride residues to be treated are ball-milled by the ball mill 1, they are put into the ball mill tank 2, and the ball-milled powder is lifted to the rotary vibrating screen 4 by the elevator 3 for screening. The particle size of the phthalic anhydride residues is l~5mm;

[0016] 2) Esterification: under stirring, add 74 grams of phthalic anhydride residue powder and 155 grams of n-butanol into the esterification reaction kettle 7 for esterification, and n-butanol passes through the n-butanol feeding pump from the n-butanol storage tank 5 6 was added to the esterification reactor 7, and at the same time, 2.22 grams of catalytic sulfuric acid was added to the esterification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com