Antibacterial rubber gloves

An antibacterial rubber glove and rubber technology, applied in the direction of protective clothing, etc., can solve the problems of water stains, easy to produce bacteria, etc., and achieve the effect of reducing cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

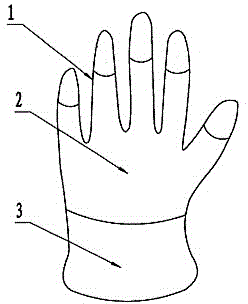

[0014] see figure 1 , providing an antibacterial rubber glove, comprising a thumb part 1, a palm part 2 and a wrist part 3, the thumb part 1, the palm part 2 and the wrist part 3 are sequentially connected from top to bottom, and the material of the glove It is rubber, and the composition of the rubber is: in parts by mass, 100 parts of acrylate rubber, 56 parts of quick extruded carbon black, 3.5 parts of N,N-nickel di-n-butyl dithiocarbamate, potassium stearate 0.7 parts, 1.5 parts of anti-aging agent, 0.8 parts of sulfur, 0.7 parts of polyvinyl butyral, and 1.4 parts of tributoxyethyl phosphate.

Embodiment 2

[0016] An antibacterial rubber glove is provided, comprising a thumb part, a palm part and a wrist part, the thumb part, the palm part and the wrist part are sequentially connected from top to bottom, the material of the glove is rubber, and the rubber The composition is: in parts by mass, 100 parts of acrylate rubber, 50 parts of quick extruded carbon black, 4 parts of nickel N,N-di-n-butyldithiocarbamate, 1 part of potassium stearate, and 1 part of anti-aging agent , 1 part of sulfur, 0.5 parts of polyvinyl butyral, and 1.5 parts of tributoxyethyl phosphate.

Embodiment 3

[0018] An antibacterial rubber glove is provided, comprising a thumb part, a palm part and a wrist part, the thumb part, the palm part and the wrist part are sequentially connected from top to bottom, the material of the glove is rubber, and the rubber The composition is: in parts by mass, 100 parts of acrylate rubber, 60 parts of quick extruded carbon black, 2.5 parts of nickel N,N-di-n-butyl dithiocarbamate, 0.5 parts of potassium stearate, 2 parts of anti-aging agent , 0.5 parts of sulfur, 1 part of polyvinyl butyral, and 1.2 parts of tributoxyethyl phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com