Rubber modification methacrylate resin composition

A methacrylate and resin composition technology, which is applied in the field of rubber-modified methacrylate resin composition, can solve the problem that the impact resistance strength is poor, and the physical properties such as impact resistance strength and heat resistance cannot be achieved. Industry requirements and other issues to achieve the effect of good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

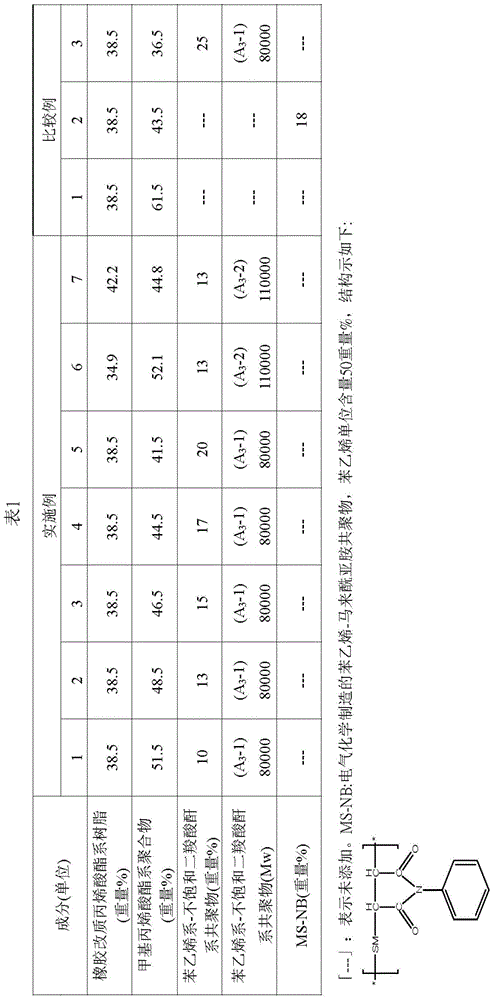

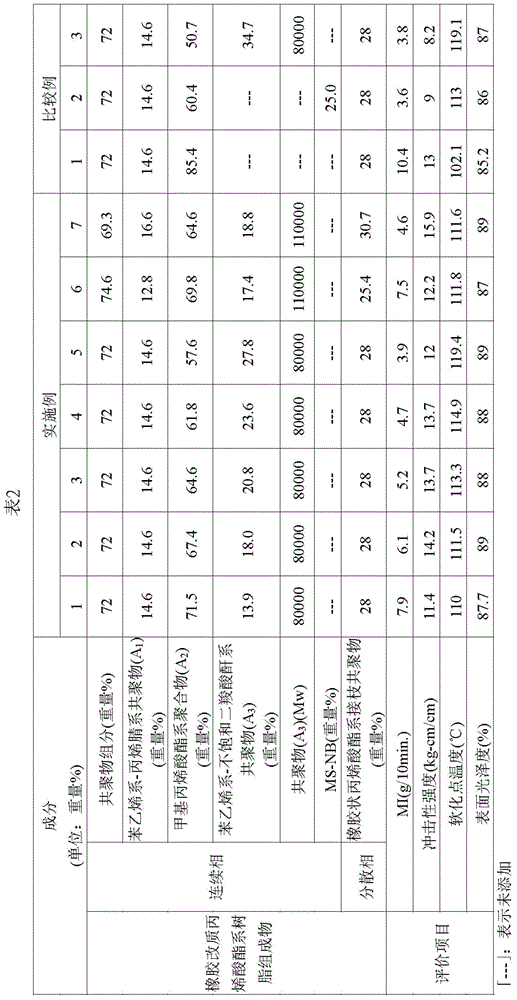

Examples

preparation example 1

[0060] [Preparation Example 1] graft copolymer mixture

[0061] Styrene-acrylonitrile copolymer (A 1 ) and rubbery acrylate graft copolymer (B) form a graft copolymer mixture, and the graft copolymer mixture manufacture method is as follows:

[0062] (1) First, the acrylic rubber emulsion with a weight average particle size of 0.1 μm is obtained by polymerizing 99.0% n-butyl acrylate and 1.0% allyl methacrylate, with a solid content of about 38% and a weight average particle size of 0.1 μm.

[0063] (2) The acrylic rubber emulsion with a weight average particle size of 0.4 μm is obtained by polymerizing 99.0% of n-butyl acrylate and 1.0% of allyl methacrylate, with a solid content of about 38% and a weight average particle size of 0.4 μm .

[0064] (3) Finally, 70% by weight of the above-mentioned acrylate rubber emulsion with a weight average particle diameter of 0.1 μm and 30% by weight of the above-mentioned acrylate rubber emulsion with a weight average particle diamete...

preparation example 2

[0067] [Preparation example 2] methacrylate copolymer (A 2 )

[0068] The product model Acryrex CM-211 manufactured by Chi Mei Corporation was used.

preparation example 3

[0069] [Preparation Example 3] Styrene-Unsaturated Dicarboxylic Anhydride Copolymer (A 3 -1)

[0070] SZ-26080 manufactured by Polyscope Corporation was used, the maleic anhydride monomer unit content was 26% by weight, the styrene monomer unit content was 74% by weight, and the weight average molecular weight was 80,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com