a rice steamer

A technology of steaming grain and grain steaming device, which is applied in the preparation of alcoholic beverages, etc., which can solve the problems of large space occupation, poor energy saving effect, and overcapacity, and achieve the effects of small space occupation, energy and water saving, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

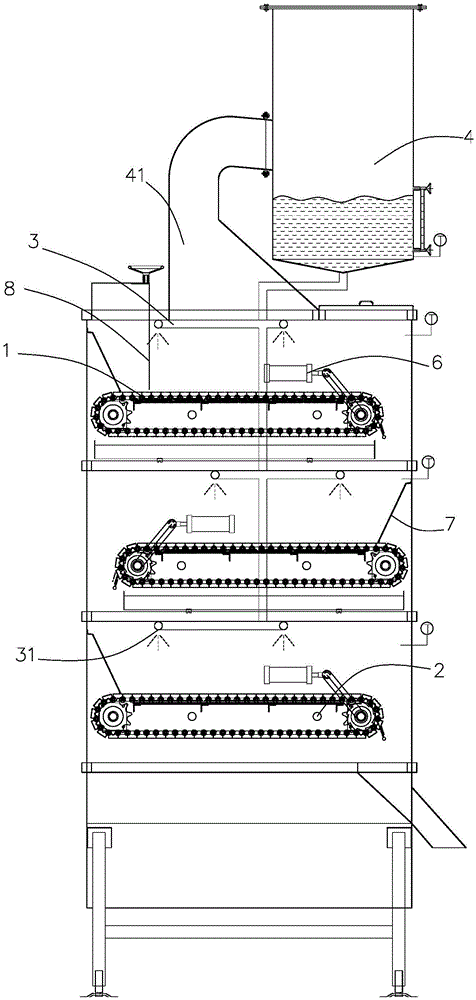

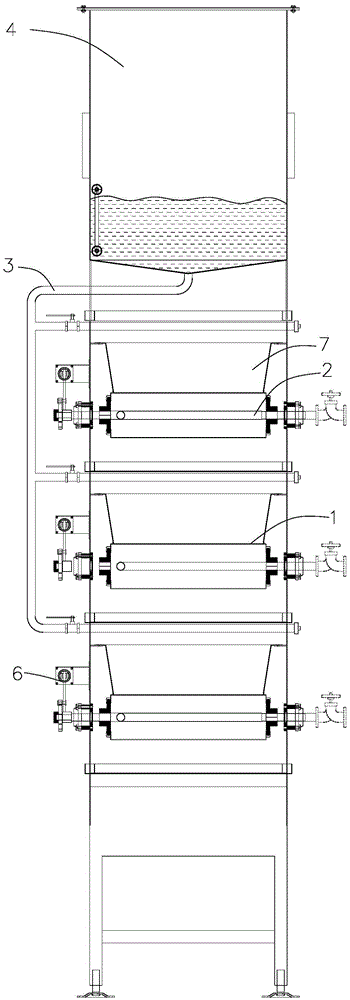

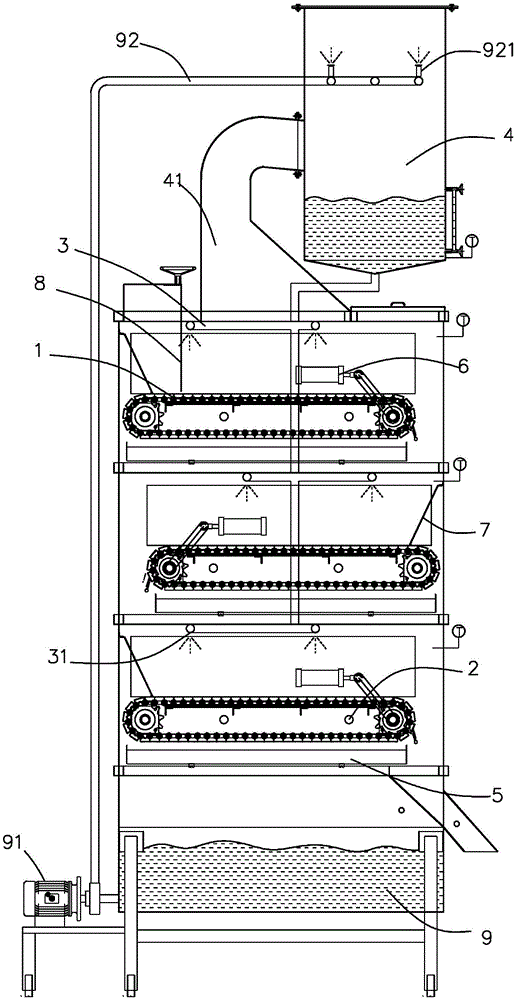

[0024] see figure 1 and figure 2 Shown is an embodiment 1 of a grain steaming machine of the present invention, comprising: a return tank 4 and a grain steaming device. The return water tank 4 is connected with a steam collecting port 41 opening downward. The number of grain steaming devices is three, or two or four or more, and such changes still fall within the protection scope of the present invention. Each grain steaming device is all arranged under the described return water tank 4, and is arranged in parallel up and down.

[0025] The grain steaming device comprises a water supply pipe 3 and a conveyor belt 1 arranged sequentially from top to bottom, the upper surface of the conveyor belt 1 is provided with a conveying channel, and the conveyor belt 1 is provided with a steam pipe 2 with a steam hole, so The water supply pipe 3 is provided with a water supply nozzle 31 and communicates with the return tank 4 , the steam pipe 2 is connected to an external steam genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com