A kind of raw shelling device of tartary buckwheat whole grain

A technology of tartary buckwheat and tartary buckwheat kernels, which is applied in the fields of application, grain processing, agriculture, etc., can solve the problems of high damage rate, many broken pieces of tartary buckwheat kernels, and decreased shelling efficiency, so as to achieve high whole kernel rate and prevent nutrition Loss of substances and health ingredients, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

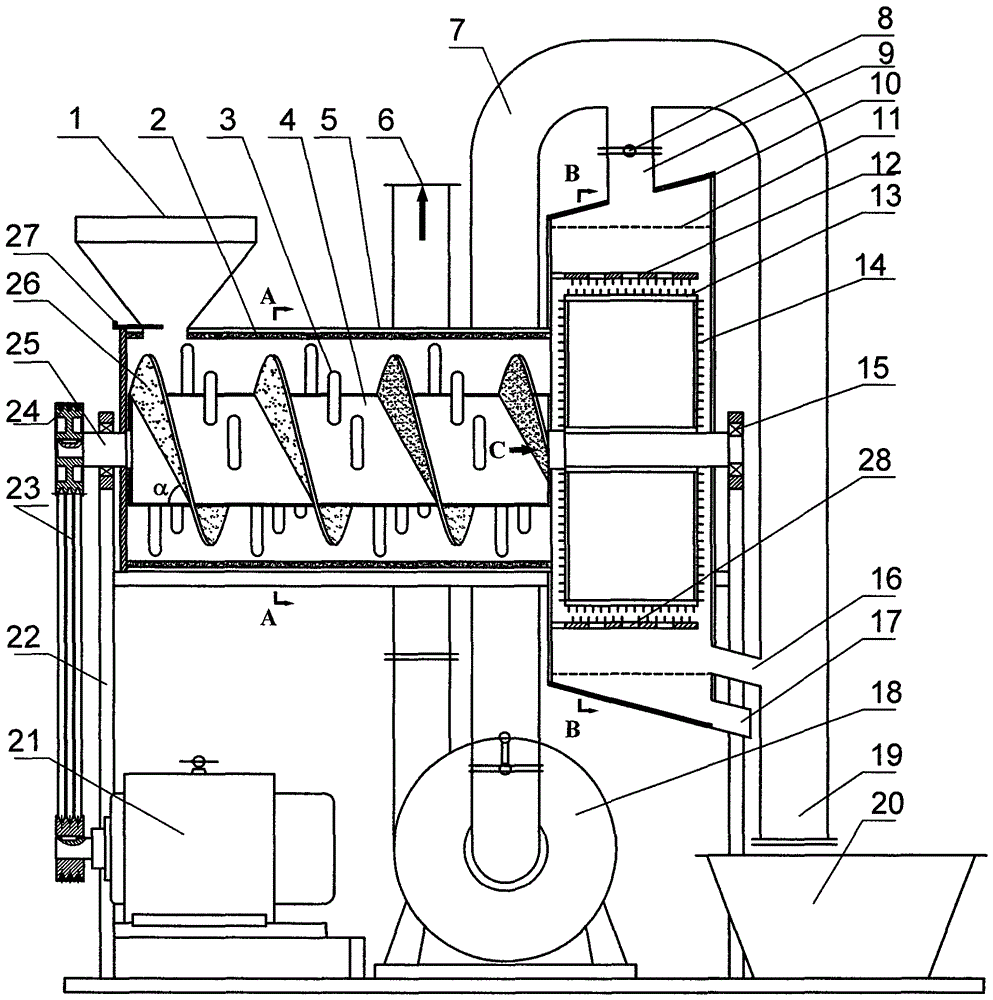

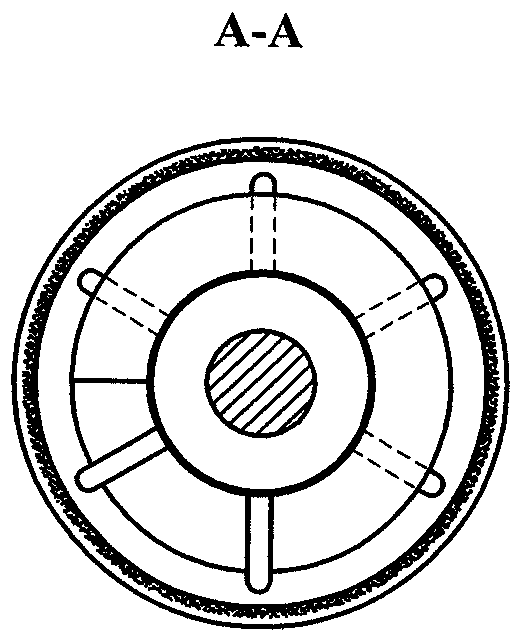

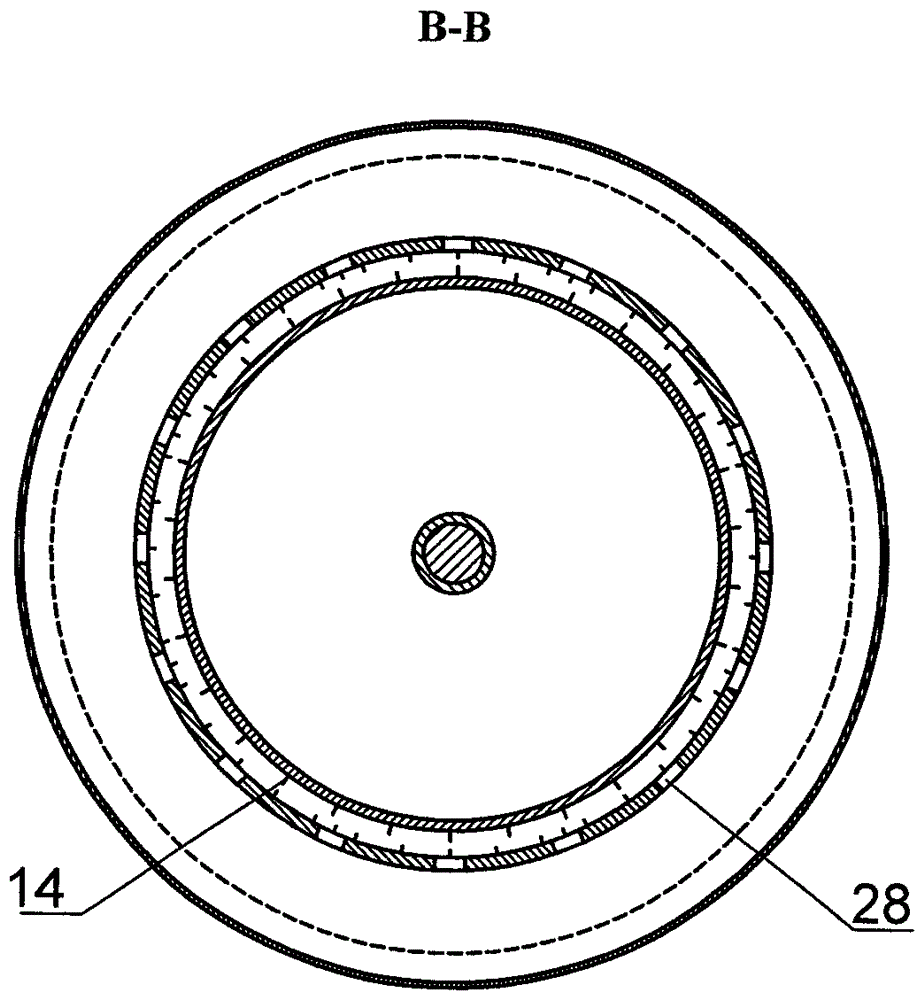

[0032] Such as figure 1As shown, a kind of tartary buckwheat whole seed shelling device of the present invention comprises a feed hopper 1, an abrasive material inner sleeve 2, a grinding rotor 4, a grinding cylinder 5, a shelling chamber 10, a screen 11, Shelling inner cylinder 13, tartary buckwheat discharge opening 16, tartary buckwheat kernel collecting hopper 20, motor 21 and frame 22, main shaft 25, winnowing device, described main shaft 25 is installed on the frame 22 by bearing 15, described The motor 21 is installed under the frame 22, and is connected with the main shaft 25 through the belt 23 and the pulley 24; the feeding hopper 1 is installed on the upper left of the grinding cylinder 5; the inner wall of the grinding cylinder 5 is fixed with an abrasive inner sleeve 2. A shelling chamber 10 is arranged at its right end; the shelling chamber 10 is directly connected to the inside of the grinding cylinder 5; the grinding rotor 4 and the shelling inner cylinder 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com