A method of improving the service life of the mud cannon nozzle of the blast furnace front equipment

A nozzle and equipment technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems affecting the tightness of the nozzle and the taphole, the roundness of the mud sleeve is not accurate enough, and the service life of the nozzle is discounted, etc. problems, to achieve the effect of reducing nozzle rupture, avoiding mud leakage and iron permeation, and prolonging the maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

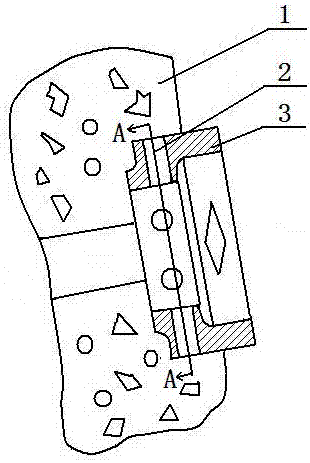

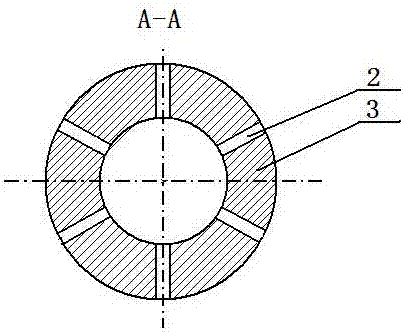

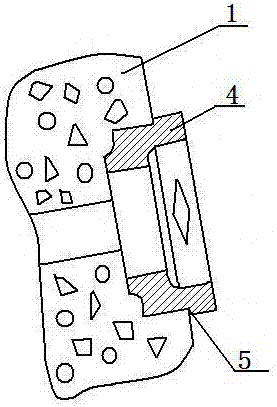

[0018] The parts and components indicated by the symbols in the accompanying drawings are as follows:

[0019] Mud sheath mold: mud sheath 1, vent hole 2, hollow cylinder 3; nozzle: cylindrical nozzle body 4, mouth step 5, pin hole 6, tangent plane 7.

[0020] The present invention will be further described below in conjunction with embodiment:

[0021] The present invention is a method for improving the service life of the mud cannon nozzle of the equipment in front of the blast furnace, including the improvement of the manufacturing method of the mud sheath and the improvement of the nozzle structure, and is characterized in that:

[0022] The manufacturing method of the mud jacket is improved as follows: use the mud jacket mold to open the mud jacket mold with air holes on the surface, and make it from refractory materials or ramming materials through three steps of mud stacking, compaction molding, and drying and curing;

[0023] The improved nozzle structure is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com