Compact false twist spindle device with novel structure

A compact and new structure technology, applied in textiles and papermaking, etc., can solve the problems of high production capacity and energy consumption, and affect the quality of false twisted textured yarn, so as to achieve high production capacity, increase spindle density and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

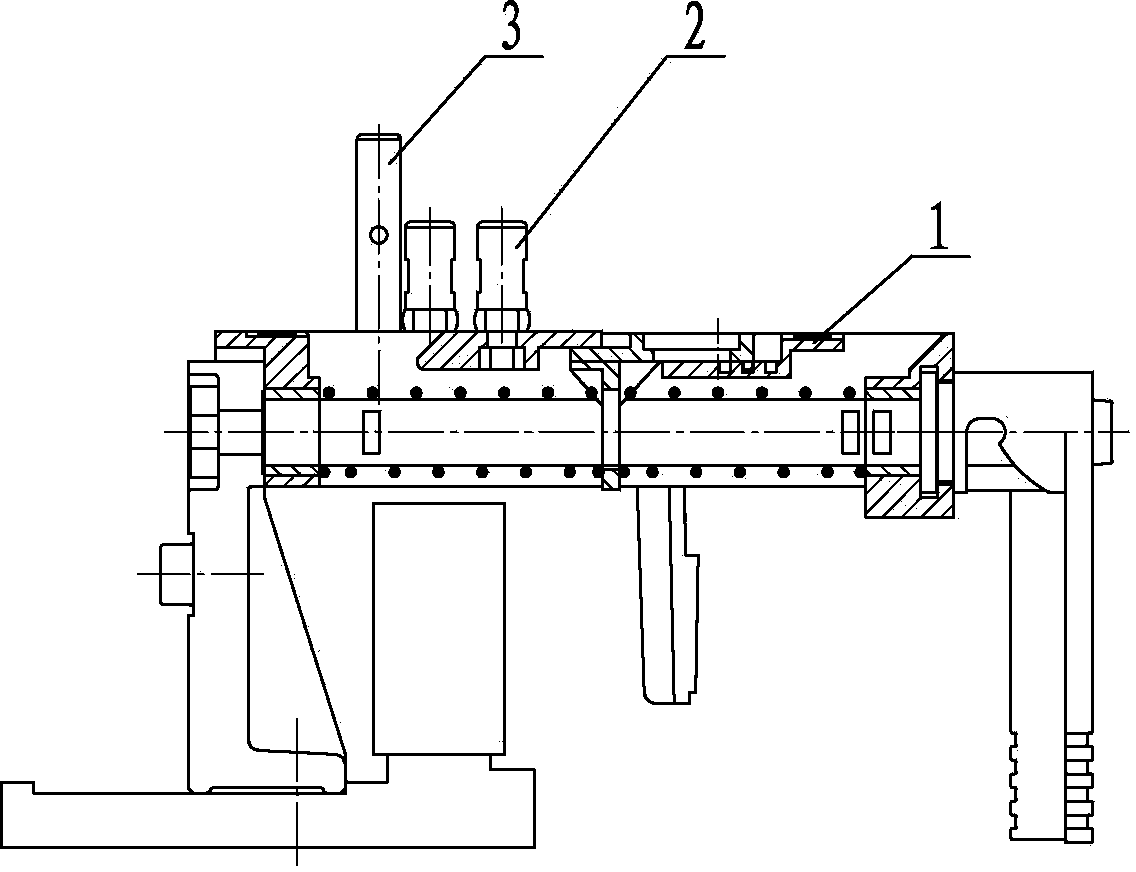

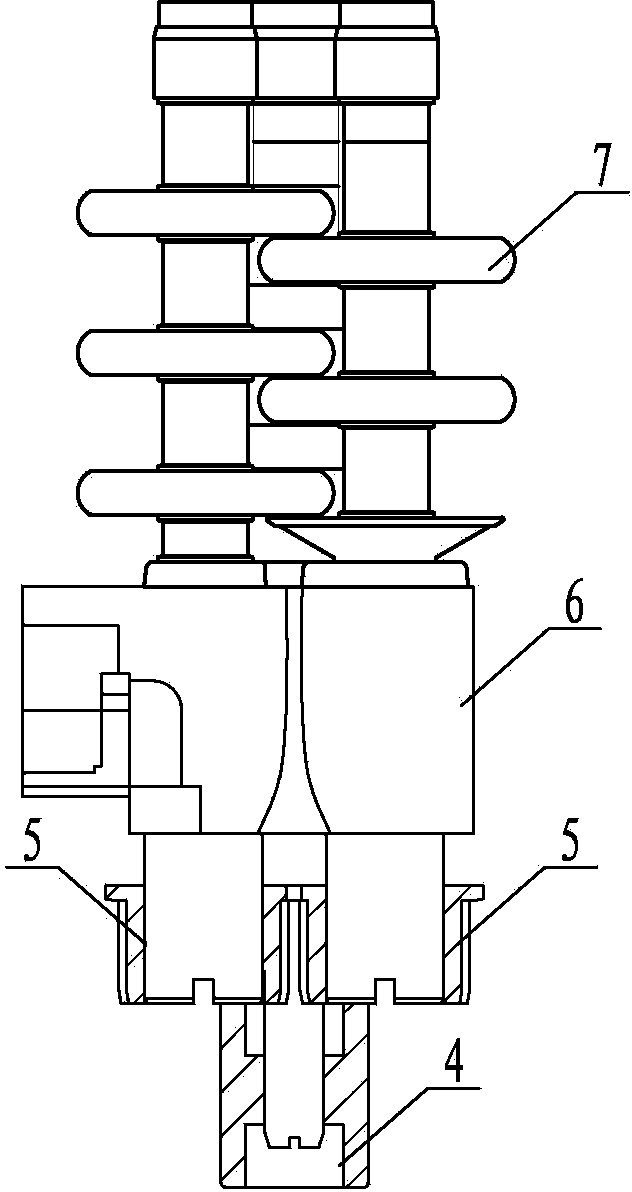

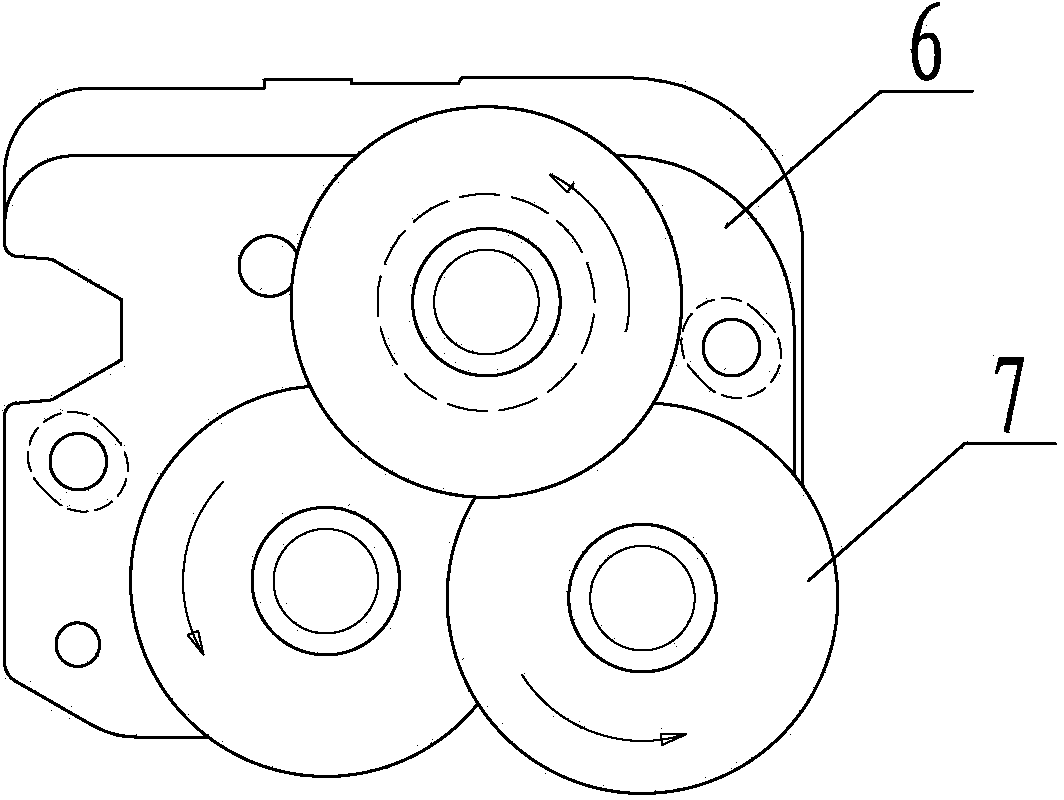

[0019] as attached figure 1 As shown in -7, the present invention includes a seat body 6 on the upper part of the false twister. Two driven bearings 5 and a driving bearing 4 are installed on the seat body 6. The center distances of their three spindle shafts form a triangle , the friction discs 7 superimposed on each other in a certain order at the center of the triangle are installed on the three spindle shafts, the driving bearing 5 and the driven bearing 4 are connected by a synchronous toothed belt, and the three spindles are connected by the toothed belt. The friction discs 7 on the shaft rotate in the same direction. The base body 6 is installed on the lower part of the false twister through a spindle position pin 3 and two fixed pins 2, and the bracket joint 1 at the lower part of the false twister adopts a lateral groove (such as Figure 8 As shown), the bracke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com