Transmission structure of fully-automatic impeller washing machine

A technology of a pulsator washing machine and a transmission structure, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of high overall material cost, complex transmission structure, and many parts, and avoid hidden dangers and defects. Simple and less parts used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

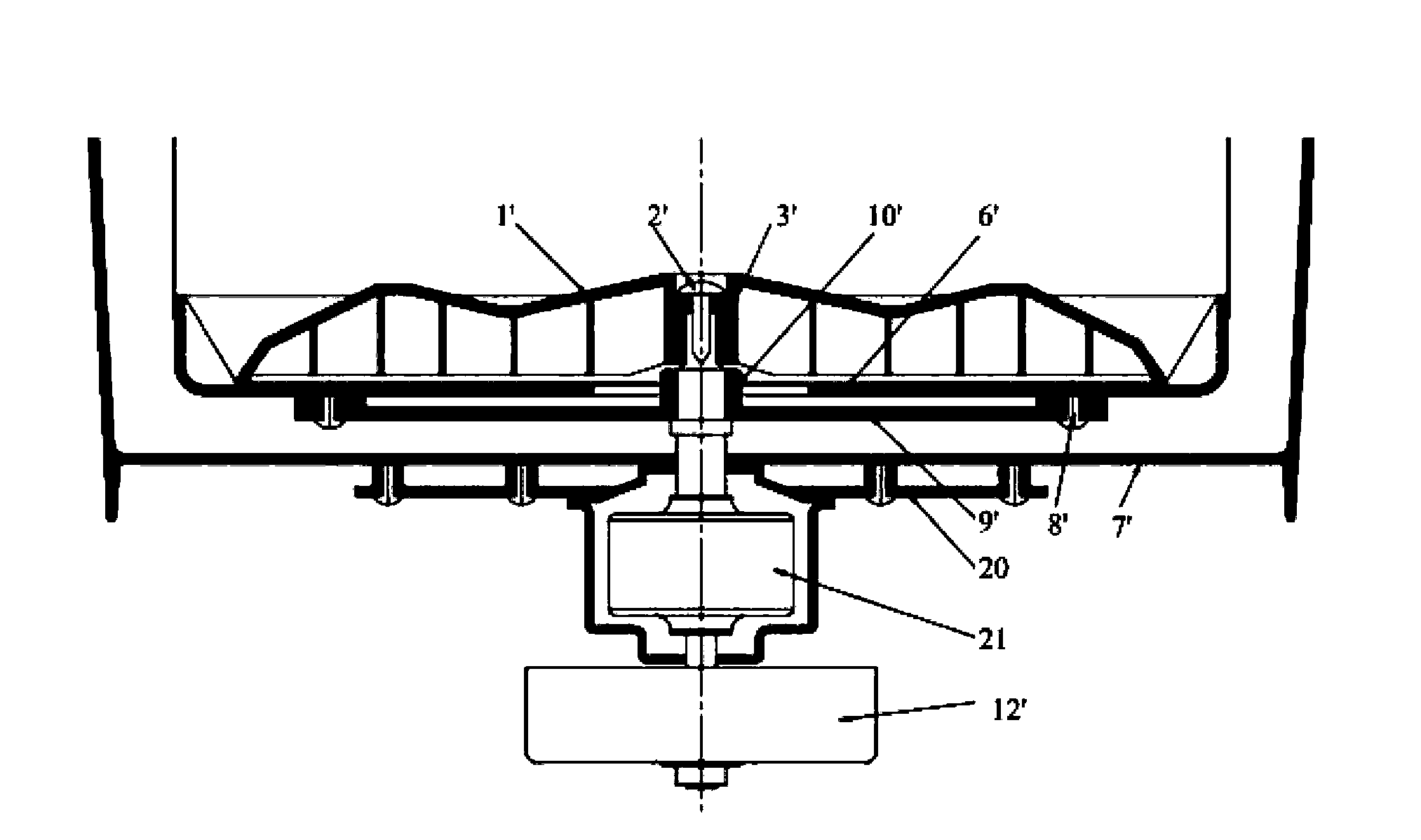

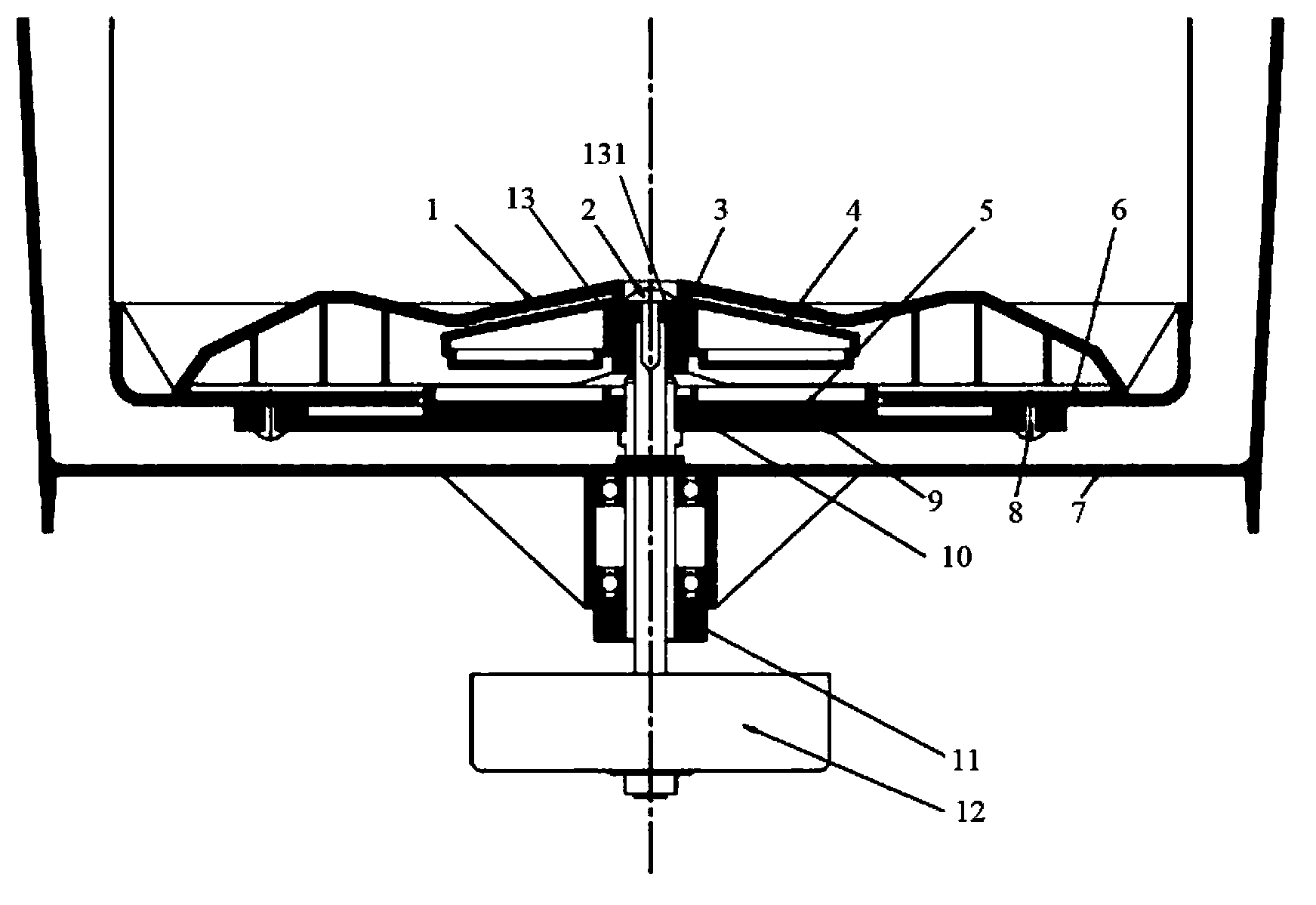

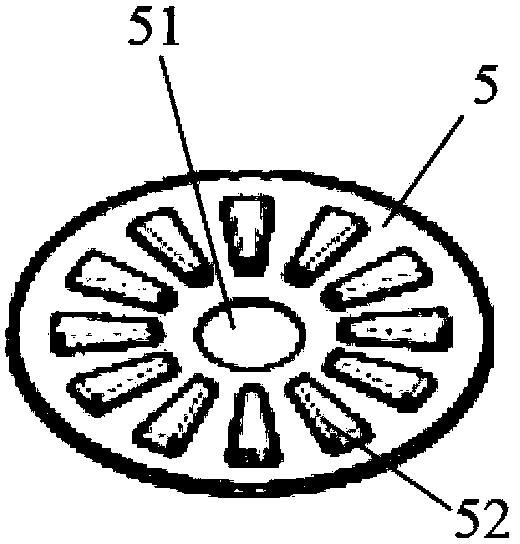

[0028] The invention discloses a transmission structure of a fully automatic pulsator washing machine, which comprises a shaft system and a coaxial motor arranged under the shaft system, an outer cylinder is fixedly installed on the shaft system, and a flange is installed on the shaft system inside the outer cylinder , the inner cylinder is fixedly installed on the flange, and the shaft system inside the inner cylinder is fixed with a pulsator. The bottom surface of the outer cylinder, the bottom surface of the inner cylinder and the flange are arranged in parallel and concentrically. The position of the center of gravity of the flange plate and the bottom surface of the outer cylinder, wherein a floating plate that slides in a vertical position is installed on the shaft system inside the pulsator, and a floating plate that penetrates the shaft system and meshes with the floating plate is fixedly installed on the flange plate. Disc base, wherein, the floating disc and the float...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com