Simple mop

A mop and simple technology, applied in the field of mops, can solve the problems of complicated use methods, cost of mop materials, and reduced utilization rate, etc., and achieve the effects of high work efficiency, increased work efficiency, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

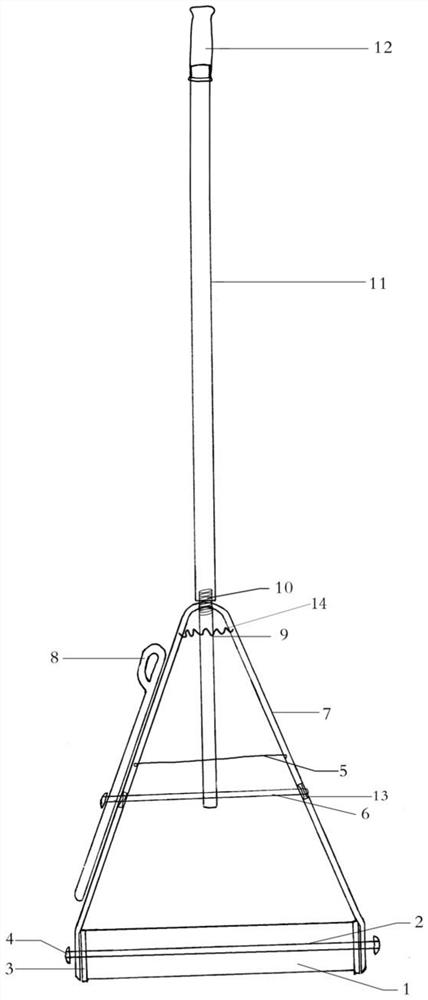

[0024] Such as figure 1 As shown, this example discloses a simple mop, which includes a mop rod 11, a mop rod bracket and a mop head connected in sequence. The upper end of the mop rod 11 is detachably connected to the cap head 12 of the mop rod, and the lower end is connected with the upper end of the mop rod support through a fastener 10; Drawbar 5, the upper end of the inverted V-shaped splint 7 is connected to the mop rod 11, and the two lower ends of the inverted V-shaped splint 7 are respectively sleeved on the horizontal axis 2 at both ends of the cleaning body 1, and can be placed on the horizontal axis 2 Sliding; the left and right sides of the inverted V-shaped splint 7 are respectively provided with a mounting hole 13 for the cross bar 6 to pass through. Shape splint 7 both sides make it extrude inwardly, loosen wrench 8 then inverted V-shaped splint 7 both sides restore to original state.

[0025] The left side of the cross bar 6 passes through the installation h...

Embodiment 2

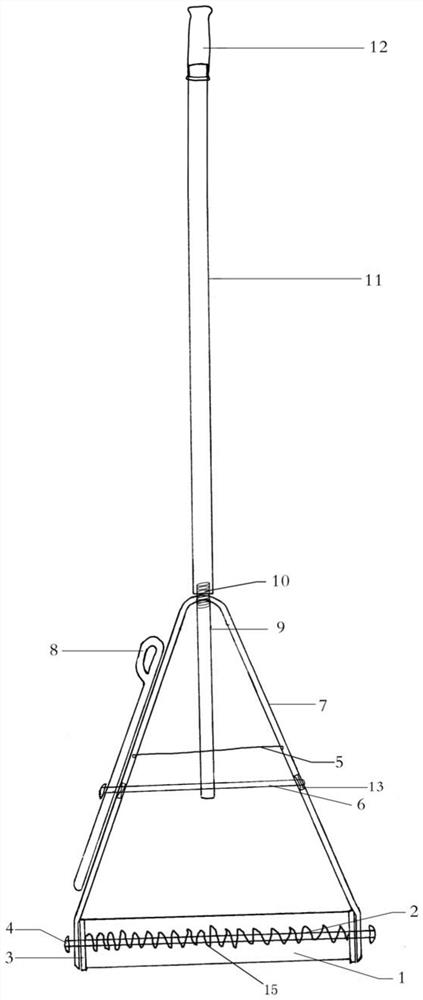

[0032] Different from Embodiment 1, the mop of this embodiment also includes a second spring 15, and the two ends of the second spring 15 are fixed to the two ends of the cleaning body 1, as figure 2 shown. Specifically, the two ends of the second spring 15 can be fixed directly with the two ends of the cleaning body, or can be fixed on the pressing pieces 3 at the two ends of the cleaning body. The second spring 15 can be sleeved on the horizontal shaft 2 , or installed between the horizontal shaft 2 and the cleaning body 1 .

[0033] Utilizing the elastic recovery force of the second spring, after the cleaning body made of sponge and other materials is compressed and squeezed out of water, when the inverted V-shaped splint is released, the cleaning body can automatically return to the unfolded state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com