Constant-power energy-saving dragging method of pumping unit

A technology of pumping unit and constant power, which is applied in the field of constant power driving energy saving method with new large torque output characteristics, can solve the problems of AC induction motor idling and other problems, achieve large starting torque, reasonable pumping speed, and improve operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The constant power dragging method of the beam pumping unit is realized by a system composed of the following parts.

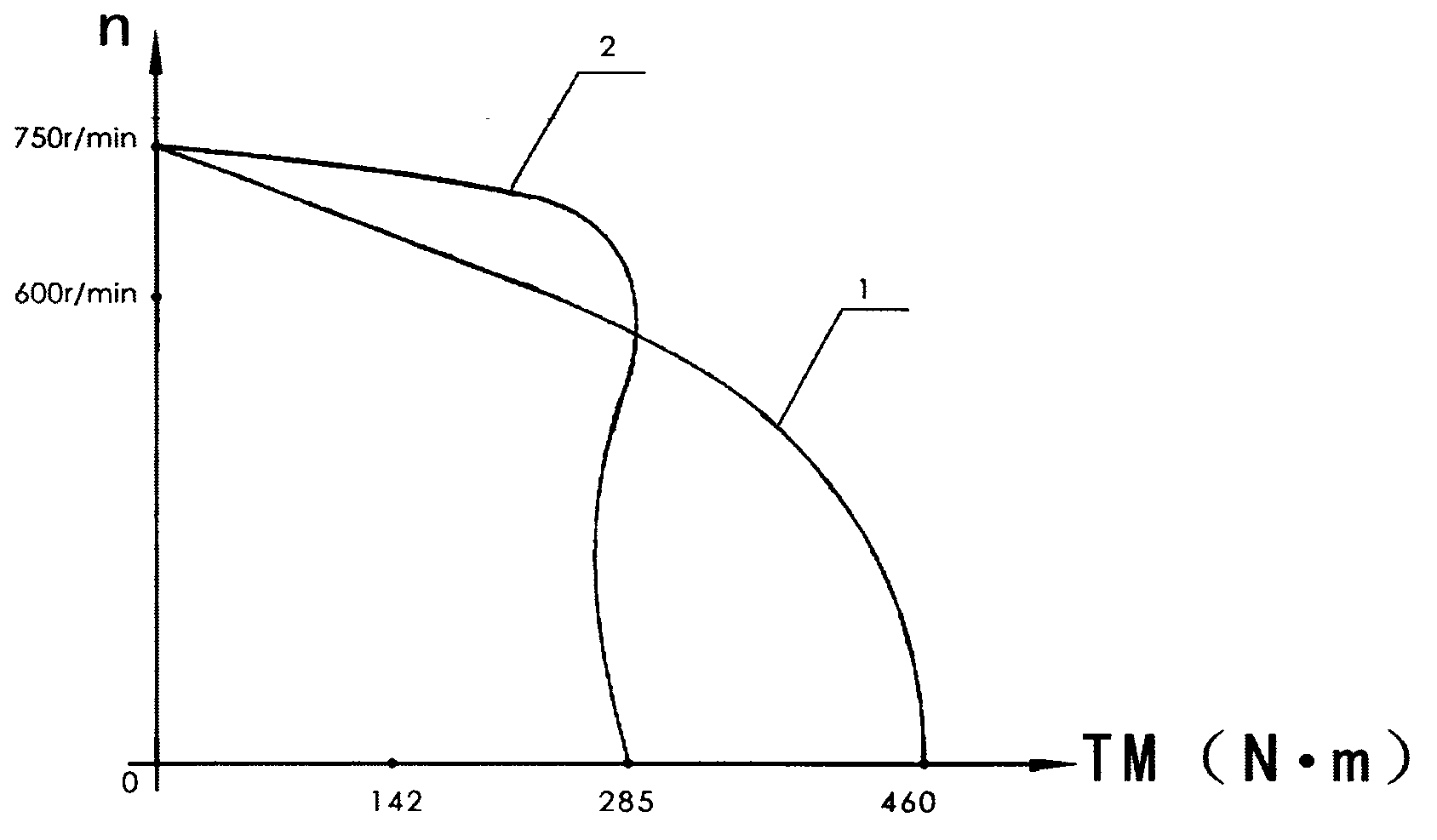

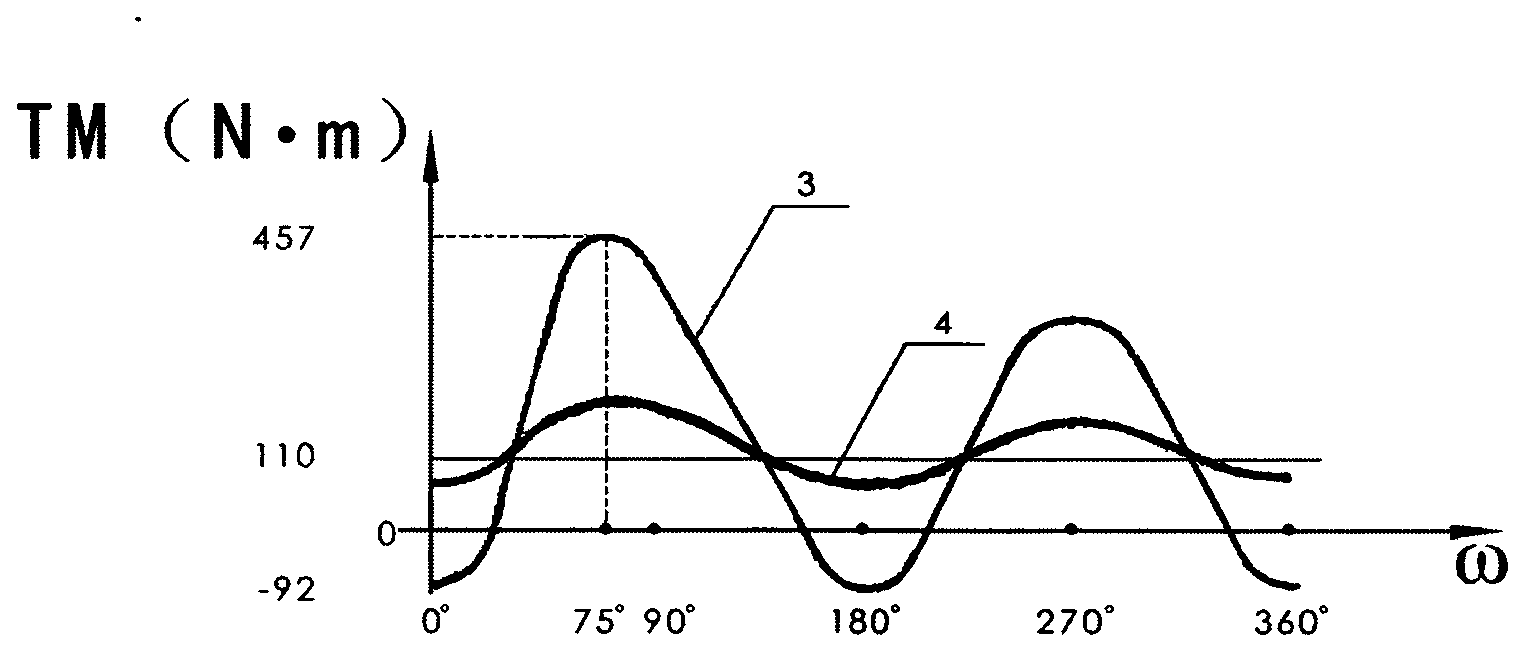

[0024] The power required by the long piston pump installed in the lower part of the oil well is passed down from the wellhead on the ground through a long tie rod of thousands of meters. The crossbeam and two long connecting rods are connected to the two crankshafts, and then connected to the AC induction motor through heavy components such as a heavy-duty reducer and a large pulley, as well as several large balance weights with a weight of several tons mounted on the rocker arm. . Due to the particularly large inertia of the entire transmission system, and the inherent transmission characteristics of the crankshaft and connecting rod on the upper stroke between 10° and 70°, the heavy-duty transmission system forms a linear motion with a large acceleration. In addition to providing the load torque required for liquid extraction and lifting, a larger i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com