High-intensity small pump uncoupling device

A disconnector and high-strength technology, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of unsuitable small pumps, etc., and achieve the effects of increasing oil pumping capacity, prolonging service life and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

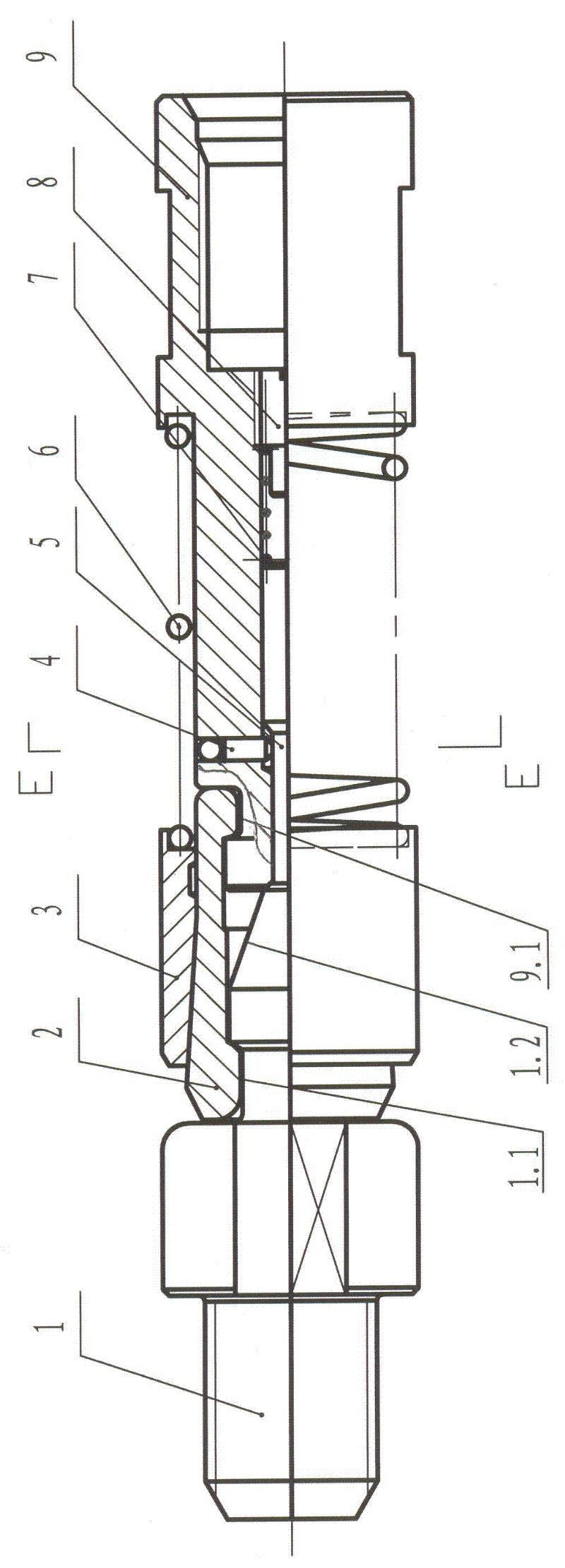

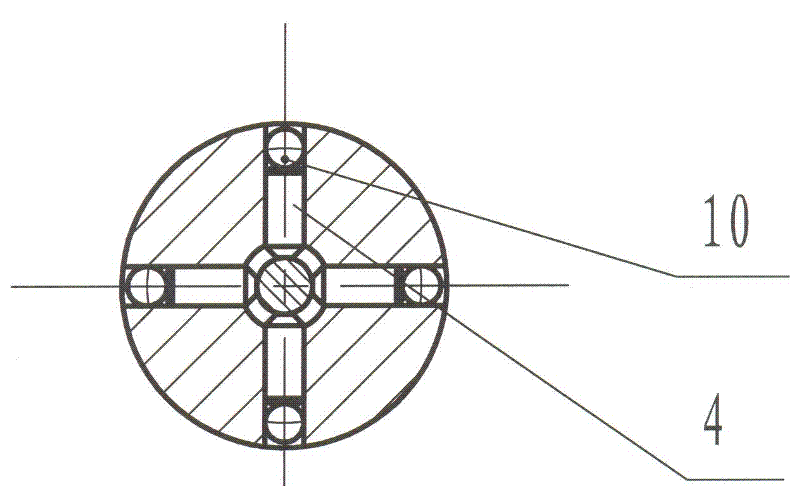

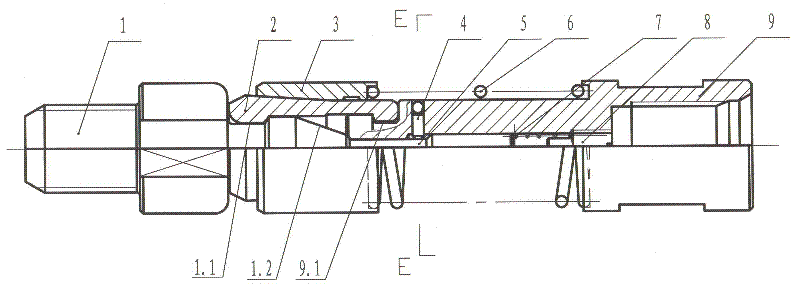

[0011] See figure 1 , 2 , the specific structure is as follows: on the outer sliding sleeve 3 of the limit short-circuit 9, the inner surface of the lock sleeve 3 is provided with an annular lock groove; A large spring 6 is set between the lower end faces of the cover 3; a spring seat 8 and a lock bar 5 are fixedly assembled in the inner hole of the limit short circuit 9, and a small spring 7 is arranged between the spring seat 8 and the lock bar 5; The thin section of the part and the thick section of the lower part are composed; the ejector rod 4 is assembled along the circumference on the limit short connection 9, the outer end of the ejector rod 4 is provided with a steel ball 10, and the inner end of the ejector rod 4 is pressed against the surface of the locking rod 5, The steel ball 10 contacts the annular lock groove of the lock sleeve 3; the upper end of the limit short 9 is provided with an annular lock groove 9.1, the upper end of the center rod 1 has an external t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com