Gas well single well gas recovery system and low-pressure recovery method thereof

A technology for gas production and gas wells, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of high energy consumption and high operating cost, and achieve the effect of high single-stage pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The natural gas wells in the middle and late stages become low-pressure gas wells due to the reduction of formation pressure. Bottom water and condensate oil will stay at the bottom of the well and form bottom-hole fluid accumulation, resulting in deterioration of production conditions and reduction of natural gas production. In order to effectively eliminate bottom-hole accumulation, increase single-well production of low-pressure gas wells, and overcome the defects of existing techniques such as jet drainage, drainage gas recovery, and gas lift, this embodiment provides a gas well single-well gas recovery system.

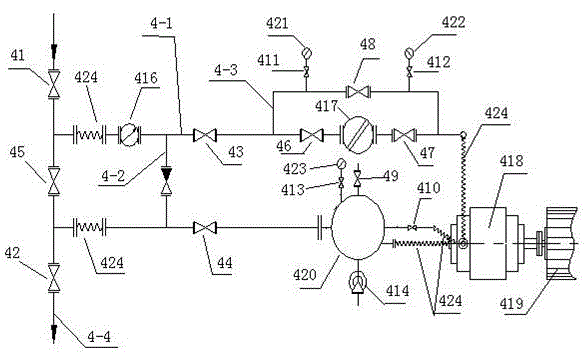

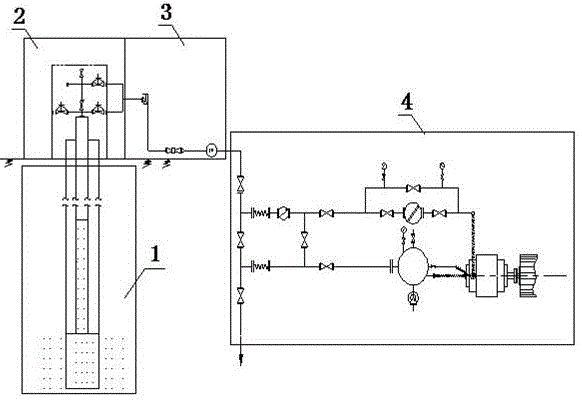

[0032] Such as figure 2 As shown, a gas well single-well gas production system includes a downhole oil casing 1, a wellhead gas production device 2, a wellhead gas production valve group 3 and a gas gathering station, which are sequentially connected through a gas production main pipe 4-4. The gas well single well gas production system of this embodiment a...

Embodiment 2

[0043] Adopt the gas well single well gas production system described in embodiment 1, combine figure 1 with figure 2 , this embodiment describes the low-pressure drainage method.

[0044] Normally, the natural gas produced by the downhole oil casing 1 and the bottomhole liquid carried in the natural gas enter the wellhead gas production valve group 3 through the wellhead gas production device 2, and are transported to the downstream gas collection through the gas production main pipe 4-4 stand. In this embodiment, a synchronous rotary pressurization integrated device 4 is installed on the main gas production pipe 4-4 between the wellhead gas production valve group 3 and the gas gathering station. The principle of synchronous rotary supercharging integrated device 4 to realize pressurization and discharge of bottom-hole fluid can be described as: through the suction effect of the synchronous rotary compressor unit in the synchronous rotary supercharging integrated device, t...

Embodiment 3

[0048] In order to compare the change of the natural gas production of a gas well single well before and after boosting, the low-pressure extraction method of the gas well single well gas production system provided by the present invention is applied to the Sulige Gas Field, and the change of the natural gas flow rate of the gas well single well before and after boosting is recorded . In order to better illustrate the beneficial effect of this method, a brief overview of the Sulige Gas Field is now given.

[0049] The Sulige gas field is a typical "low pressure, low permeability, and low abundance" three-low gas field. It is very difficult to develop, and effective development is a world-class problem. Single well production is low, with an average of only 1×10 4 m 3 / d, the original formation pressure of the gas well is as high as above 25MPa; after the well is opened, the pressure drops below 5MPa within a short period of time (6-8 months). Current pressurization situation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com