Separate-type pulverized coal nozzle

A separate, pulverized coal technology, which is applied in the direction of burners, combustion methods, and types of combustion of powdered fuel, can solve problems that plague the development of power plants, power plant economics, safety, and NOx emissions. Effects of coking, low NOx emission and flexible arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

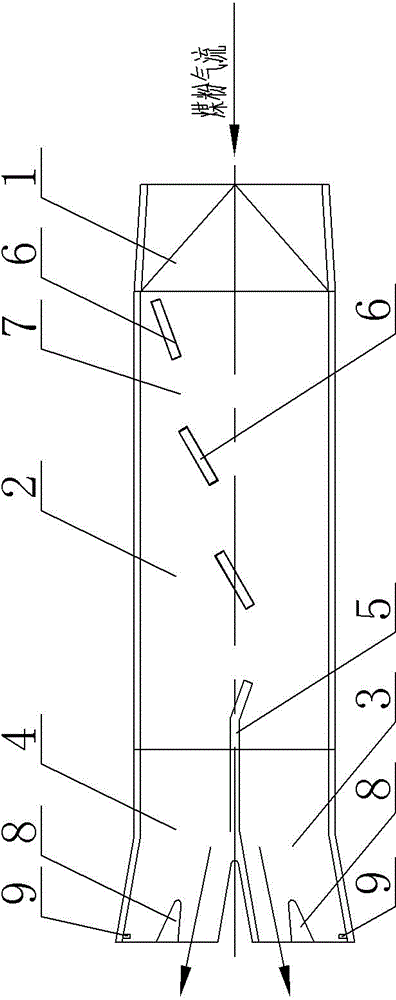

[0013] Specific embodiment one, see figure 1 : When the nozzle outlet 3 on the rich side is located below the nozzle outlet 4 on the light side, the guide plates 6 are arranged at intervals from top to bottom along the direction of the pulverized coal flow, and each guide plate 6 is inclined downward along the direction of the pulverized coal flow. The guide plate 6 is located above the inlet height of the nozzle outlet 3 on the rich side.

specific Embodiment 2

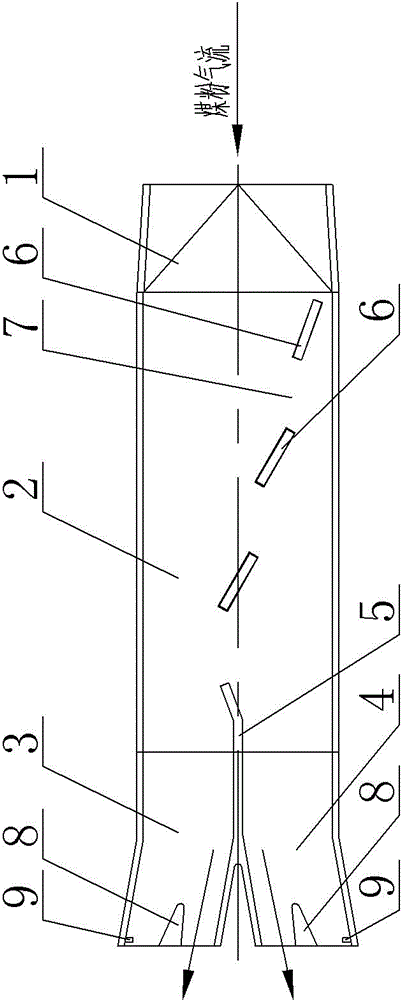

[0014] Specific embodiment two, see figure 2 : When the nozzle outlet 3 on the rich side is located above the nozzle outlet 4 on the light side, the guide plates 6 are arranged at intervals from bottom to top along the direction of the pulverized coal flow, and each guide plate 6 is inclined upward along the direction of the pulverized coal flow. 6 is located below the inlet height of the nozzle outlet 3 on the rich side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com