Semiconductor LED fluorescent packaging structure

A packaging structure and semiconductor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low efficiency and low efficiency of phosphors, and achieve the effects of improving light efficiency, reducing total reflection, and improving light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

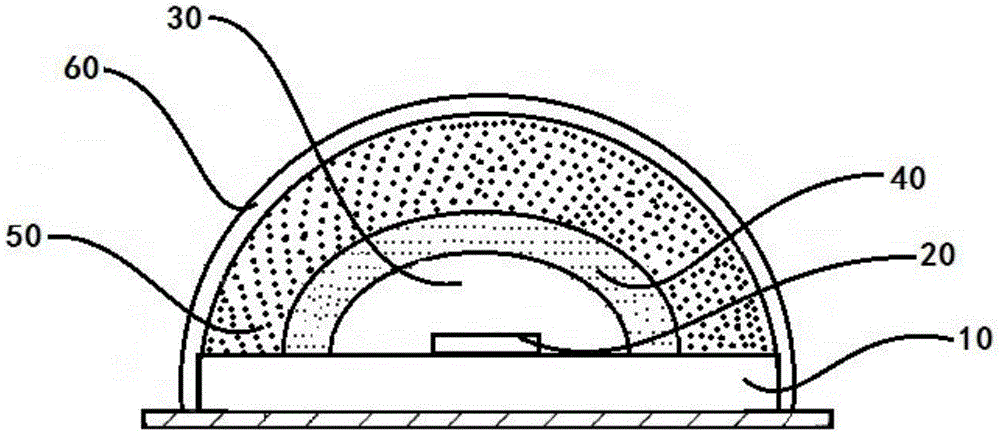

Embodiment 1

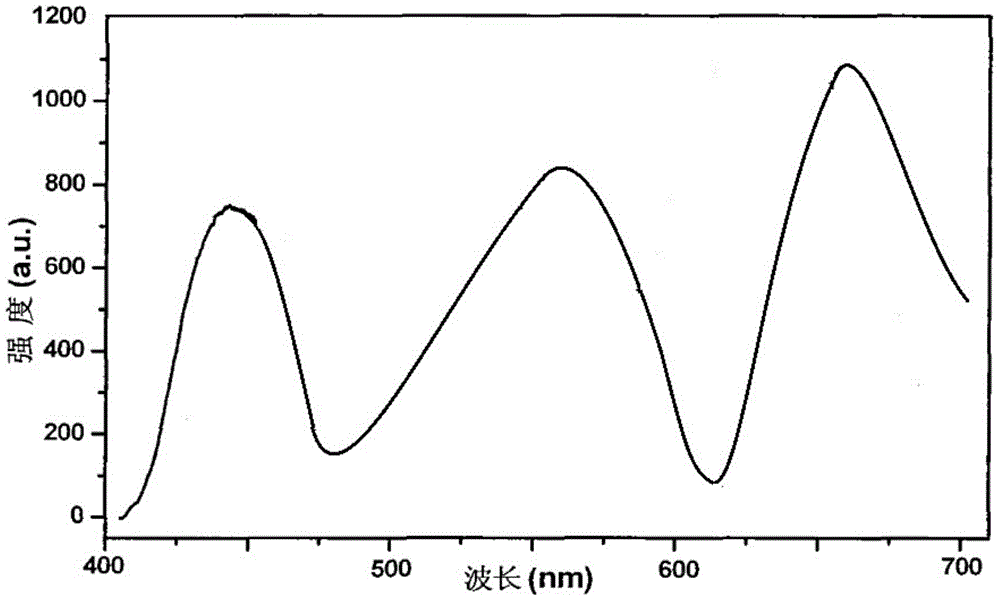

[0024] The phosphor contained in the first phosphor layer is Eu 26 al 12 Ca 2 MnO 60 . The phosphor contained in the second phosphor layer is Eu 15 Y 3 Ba 2 mn 1 o 30 . The average particle size of the phosphors is 4.2 μm. Using silicone resin as the transparent material, mixing the fluorescent powder with the transparent material, heating and curing to form the first fluorescent layer and the second fluorescent layer. The transparent resin of the first transparent diffuse reflection layer and the second transparent diffuse reflection layer is also selected from silicone resin. And use the blue LED package to form an attached figure 1 Package structure shown (without clear protective layer). After running the LED, measure its excitation spectrum, the result is as attached figure 2 shown.

[0025] transparent protective layer

[0026] In the present invention, the transparent protective layer can provide sufficient protection for the fluorescent layer, has good ...

Embodiment 2

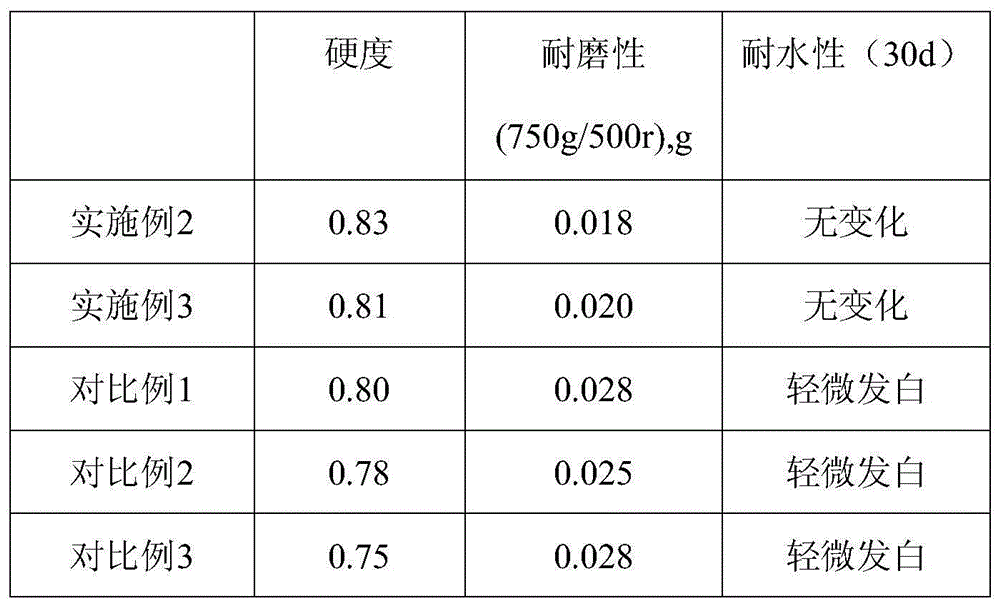

[0028] The transparent protective layer described in this embodiment has a thickness of about 500 μm, which is composed of 21.0wt% MDI, 15.0wt% PEG1000, 4.0wt% terephthalic acid, 1.3wt% trimethylolpropane, 1.2wt% % of ethoxylated bisphenol F diacrylate, 2.0wt% of phenylthioethane ethyl acrylic acid, 1.5wt% of 2-undecylimidazole, 0.15wt% of defoamer BYK-052, 0.15wt% of Leveling agent BYK-307, 0.20wt% dibutyltin dilaurate, 5.5wt% nano-alumina, 8.0wt% isopropanol and the rest of butyl acetate at a stirring speed of 300-400 rpm, Stir for 30 minutes to obtain a prepolymer, and then apply and cure at 100° C. for 30 minutes.

Embodiment 3

[0030] The transparent protective layer described in this embodiment has a thickness of about 500 μm, which is composed of 20.5wt% MDI, 13.5wt% PEG1000, 3.5wt% terephthalic acid, 1.2wt% trimethylolpropane, 1.1wt% % of ethoxylated bisphenol F diacrylate, 2.2wt% of phenylthioethane ethyl acrylic acid, 1.8wt% of 2-undecylimidazole, 0.15wt% of defoamer BYK-052, 0.15wt% of Leveling agent BYK-307, 0.20wt% of dibutyltin dilaurate, 5.0wt% of nano-alumina, 7.5wt% of isopropanol and the rest of butyl acetate at a stirring speed of 300 to 400 rpm, Stir for 30 minutes to obtain a prepolymer, and then apply and cure at 100° C. for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com