Bus mounting and fixing device

A fixing device and busbar technology, applied in the direction of open busbar installation, etc., can solve the problems of excessive force and easy damage at the corner of the bracket, achieve good fixing effect, improve product performance, and ensure safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

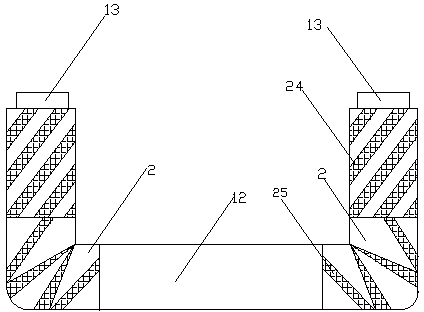

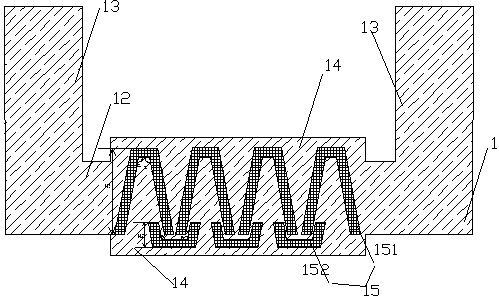

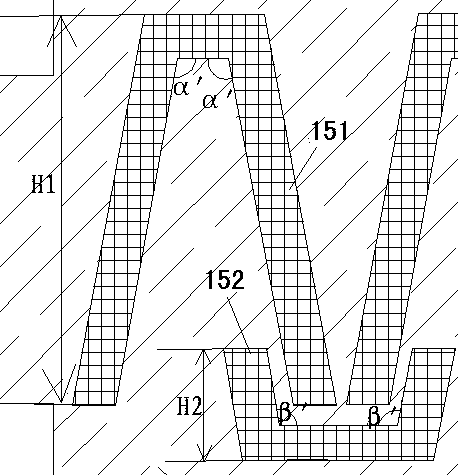

[0029] As shown in the figure, a busbar installation and fixing device includes a load-bearing bracket 1 and a pressure-bearing component 2, wherein the load-bearing bracket 1 includes a beam 12 and a support arm 13, and the beam is located in the middle of the two support arms 13 in a U-shaped structure , the load-bearing bracket 1 is an integrated structure; the upper and lower ends of the beam 12 are respectively provided with square protrusions 14, and the beam 12 is provided with a load-bearing member 15, and the load-bearing member 15 includes a first load-bearing member 151 and a second load-bearing member. Two load-bearing members 152, the cross-section of the first load-bearing member 151 is an inverted V-shaped structure; the cross-section of the second load-bearing member 152 is a U-shaped structure; the second load-bearing member 152 covers the bottom connection of the first load-bearing member 151; The ratio of the height H1 of the first load-bearing member 151 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com