Rotary demister

A demister and porous media technology, applied in external electrostatic separators, chemical instruments and methods, electrode cleaning, etc., can solve problems such as inapplicability of demisting, short circuit, loss of inertial capture effect, etc., to avoid short circuit phenomenon, Improve the collection efficiency and the effect of high-efficiency collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

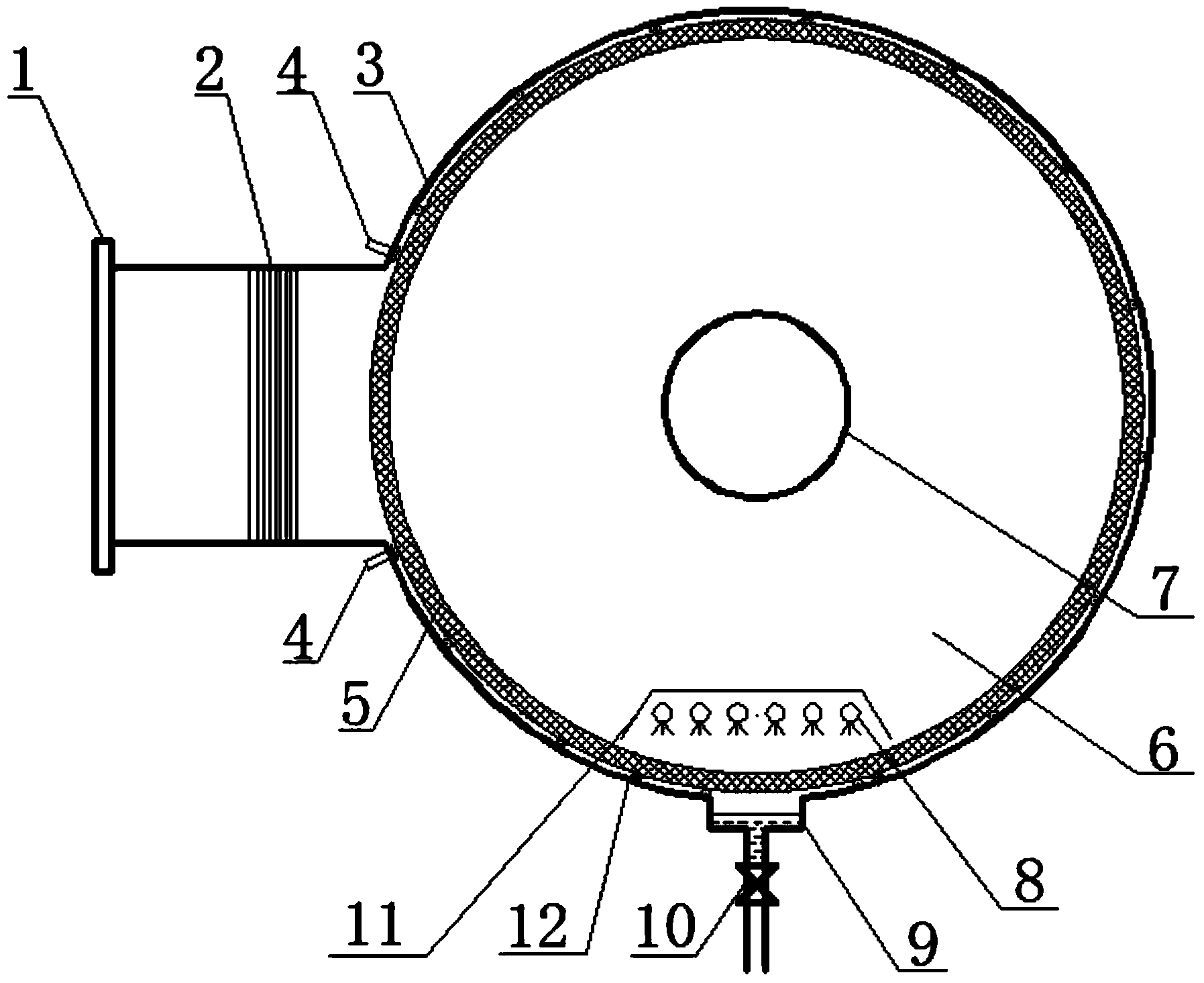

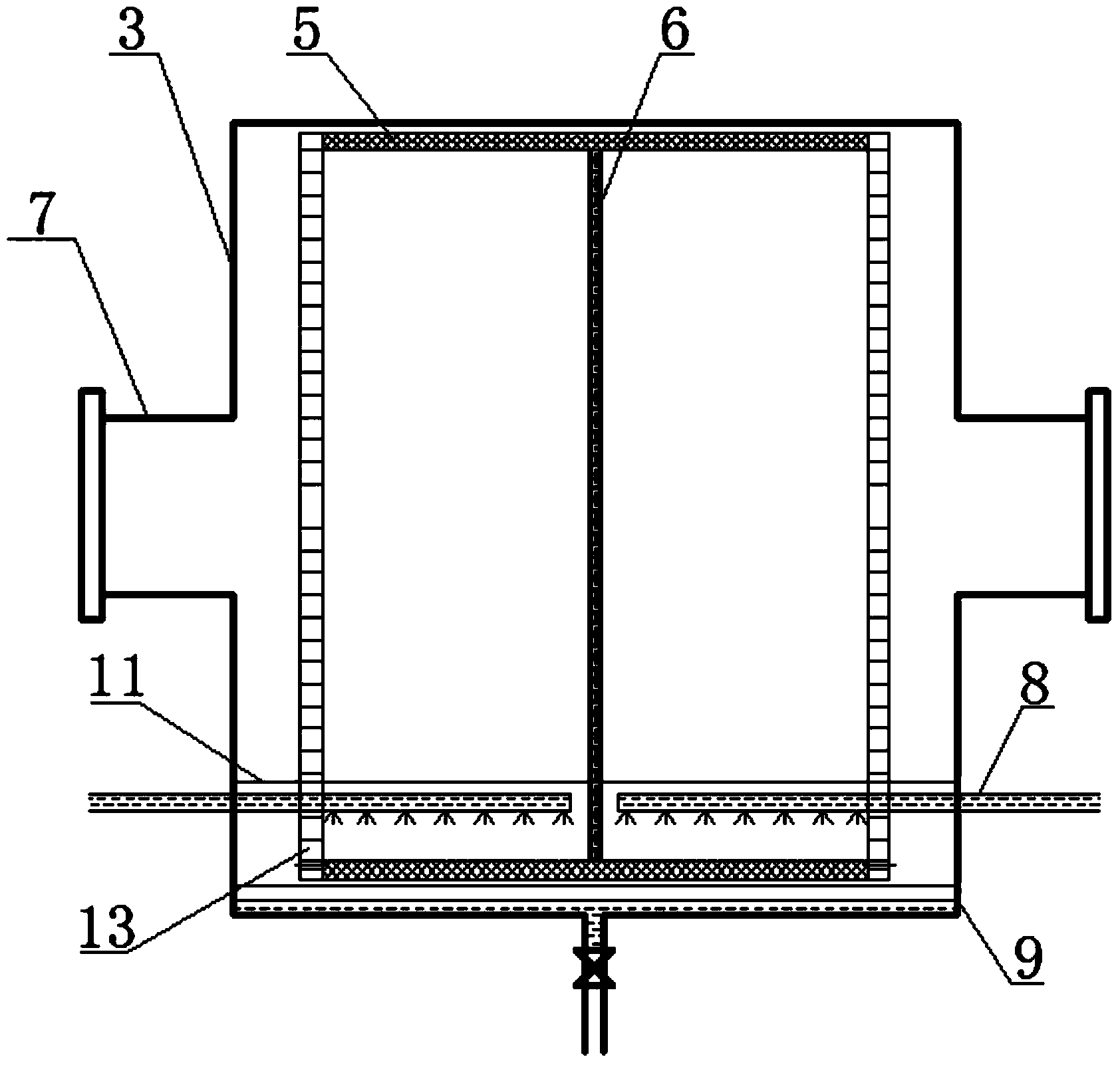

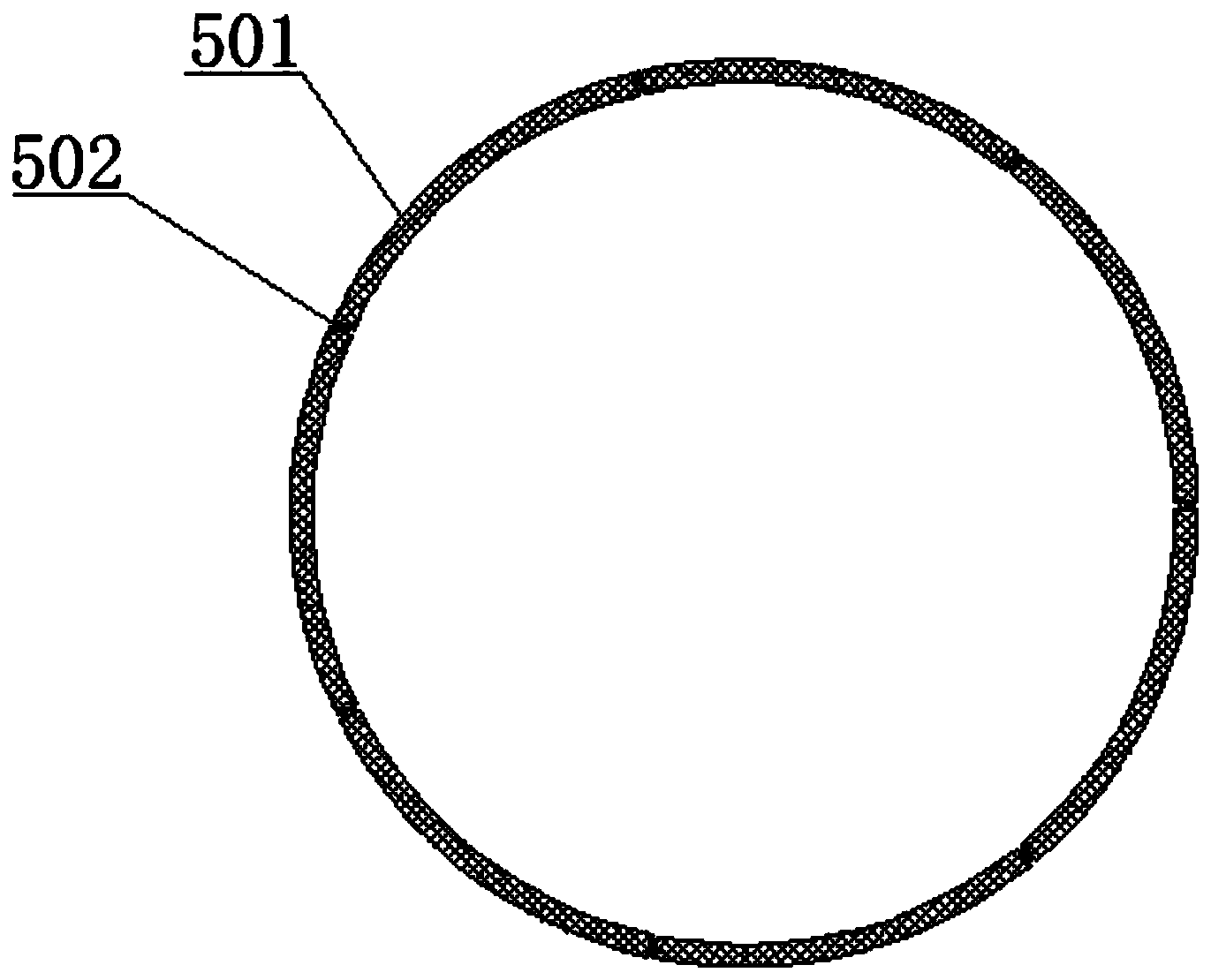

[0021] see figure 1 and figure 2 , the present invention includes a demister cylinder 3 provided with an air inlet pipe 1, a compression spring electrode 4, an air outlet 7 and a liquid discharge tank 9, a cathode line 2 arranged inside the cylinder 3, and a drum structure porous medium filter layer 5 , support clapboard 6 and roller 12, also comprise the cleaning of spray pipe 8, throttle valve 10 and clapboard 11 and its isolation structure and gear mechanism 13, intake pipe 1, cylinder body 3, drum structure porous medium filter layer 5 Coincides with the central axis of the air outlet 7.

[0022] When working, the flue gas entering from the intake pipe 1 enters the electric field formed by the strong voltage formed by the cathode line 2 and the drum structure porous medium filter layer 5 connected to the compression spring electrode 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com