Air dust collection equipment and air purifying device comprising same

A technology of air purification device and dust collection equipment, which is applied in the direction of electrode conveying device, external electrostatic separator, electrode structure, etc., which can solve the problems of dielectric strength drop, electrode breakdown, filter unusable, etc., and achieve creepage distance Effect of increasing, enhancing charge retention, reducing the risk of electrode breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

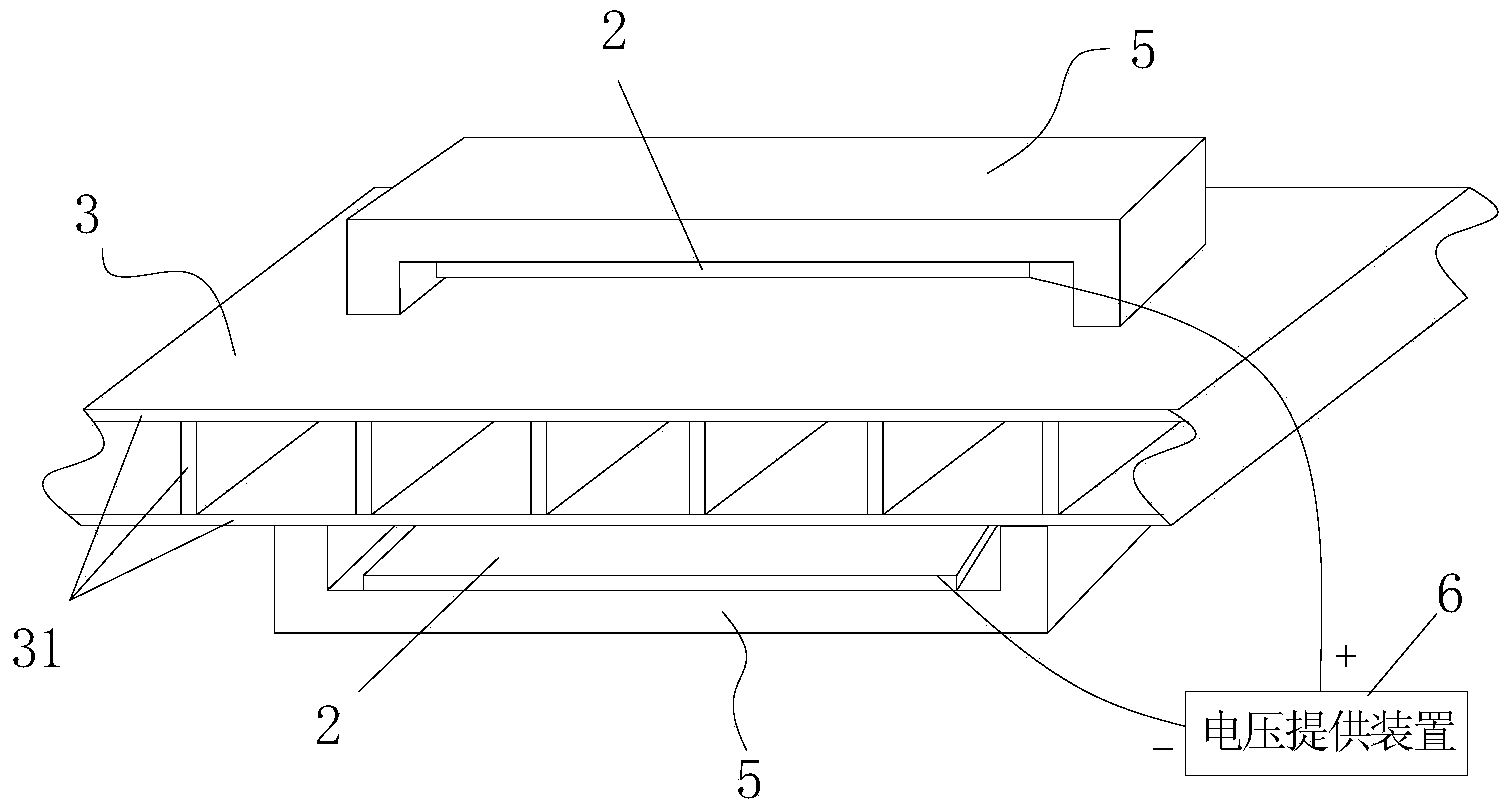

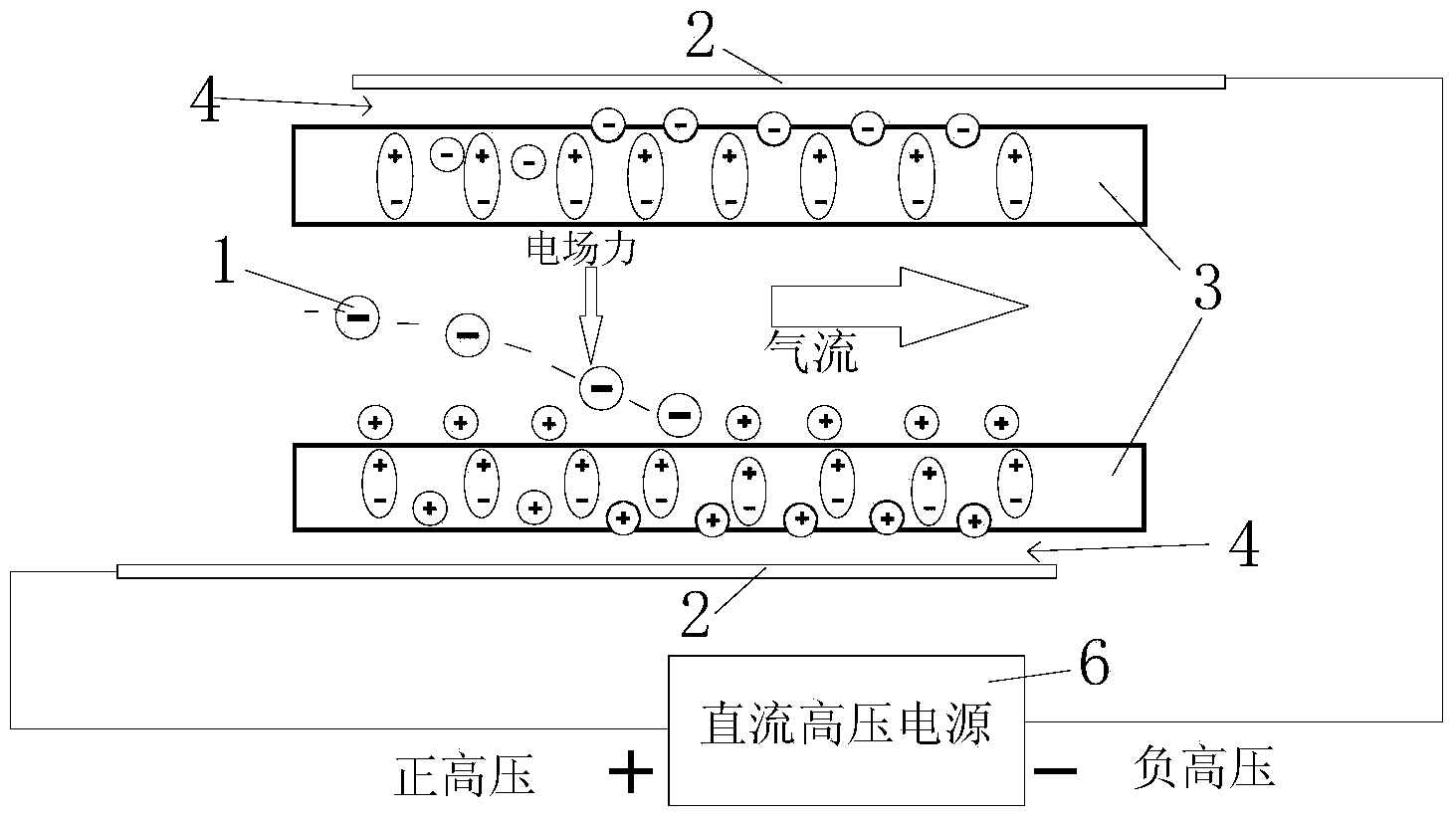

[0044] Such as figure 2 and image 3As shown, the air dust collection equipment of this embodiment includes a dust collection plate 3 surrounded by plates with more than one dust collection channel for air to pass through, an electrode bracket 5 arranged on the surface of the dust collection plate, and an electrode bracket 5 arranged on the surface of the dust collection plate. The conductive material layer 2 forming an air gap 4 between the electrode support 5 and the dust collecting plate 3 , and a voltage supply device 6 electrically connected to the conductive material layer are composed.

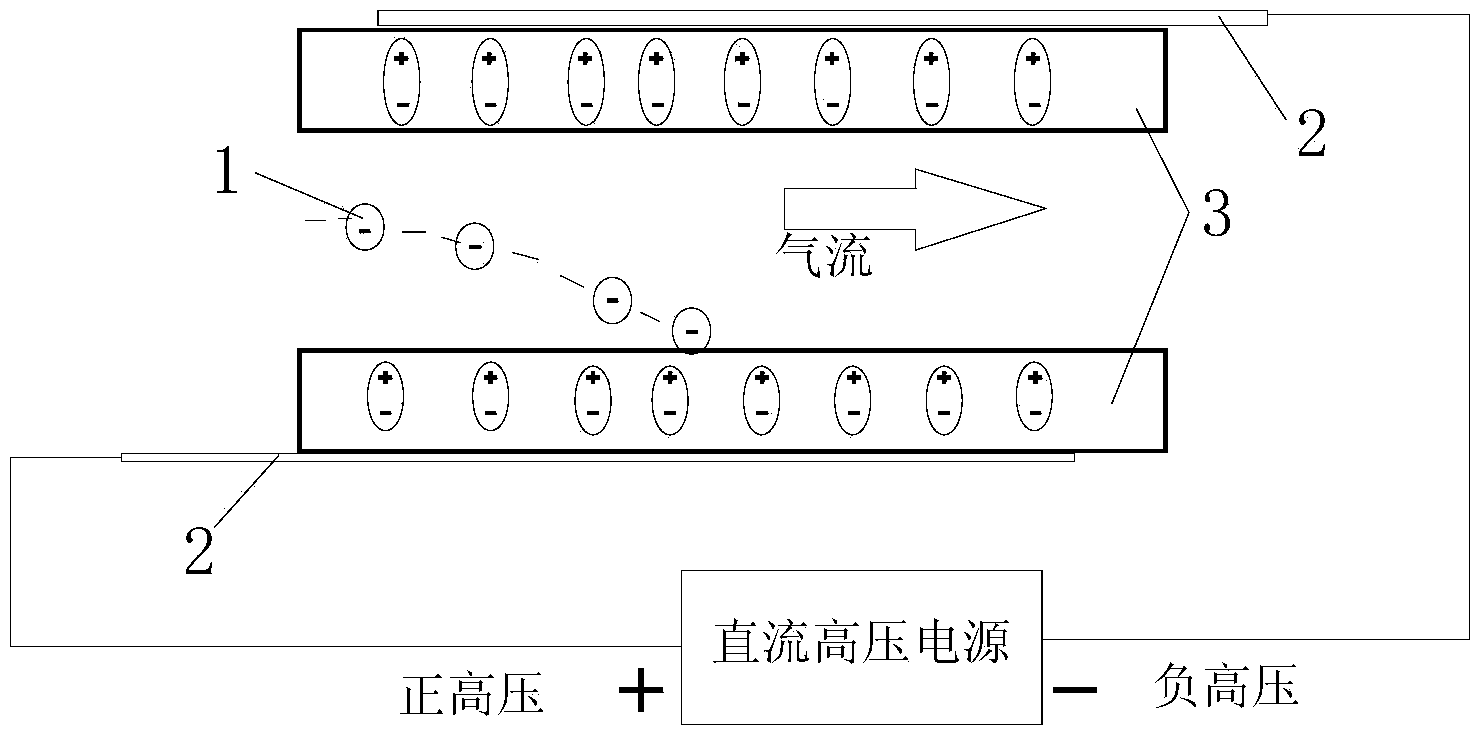

[0045] image 3 The middle airflow flows from the left side to the right side of the dust collection channel, where the electrode bracket is not drawn. In the figure, the lower conductive material layer is connected to the positive high-voltage output terminal of the DC high-voltage power supply, and the upper conductive material layer is connected to the negative high-voltage output...

Embodiment 2

[0049] The difference between this embodiment and the first embodiment is that it further includes an air driving device for driving air to pass through the dust collection channel. The air-driven device can be a blowing fan arranged at one end of the dust collection passage, or a suction fan. Through the function of the fan, the air can be quickly and effectively pushed to the dust collection channel, so as to accelerate the purification of charged particles in the air.

Embodiment 3

[0051] This embodiment is improved on the basis of embodiment one or two. Such as image 3 As shown, each electrode support 5 in this embodiment includes two support feet 51 and a support plate 52 . The support plate 52 is a long plate structure, its area is larger than the surface area of the conductive material layer 2, its two ends are respectively connected to the middle of the support foot 51, and the entire electrode support 5 forms a symmetrical structure along the plane of the support plate. Since the electrode bracket is arranged between the two dust-collecting passages, its bracket feet are respectively in contact with the adjacent dust-collecting plates, and the conductive material layer is closely attached to the two planes of the bracket plate 52 . The conductive material layer 2 on the two planes of the support plate 52 may be in a conducting state or in an insulating state. When the material of the support plate 52 is a metal material, the two conductive mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com