Micro-airflow sand belt position detection device and control method for broadband sander

A wide-band sanding machine and detection device technology, which is applied to belt grinders, workpiece feed motion control, manufacturing tools, etc., can solve problems such as poor internal environment of the machine and affect the normal use of the machine, and achieve timely correction and detection. Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

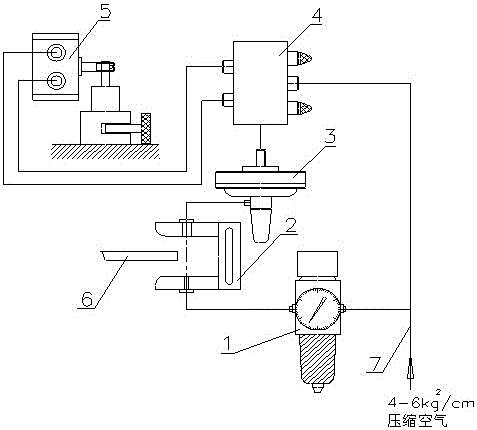

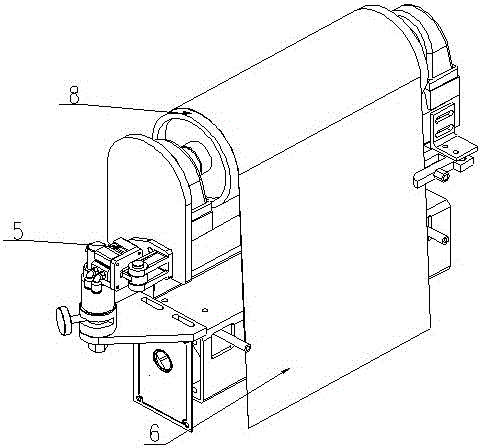

[0011] Embodiment 1: with reference to attached Figure 1-3 . A device for detecting the position of the micro-airflow abrasive belt of a wide-band sander. The compressed air pipeline 7 communicates with the inlet end of the reversing valve 4 through a three-way connection, and communicates with the inlet end of the blowing pressure regulating valve 1 through a three-way connection. The air outlet of the pressure valve 1 communicates with the air inlet of the small air hole in the air control board 2, and the air blown from the outlet of the air inlet end of the small air hole in the air control board 2 blows into the air inlet of the large air hole opposite to the small air hole in the air control board 2 Accept the airflow, the airflow at the air outlet end of the large hole communicates with the air inlet end of the air pressure amplifier 3 through the air circuit, and the air flow passes through the air pressure amplifier 3 to increase force and push the thimble to realize...

Embodiment 2

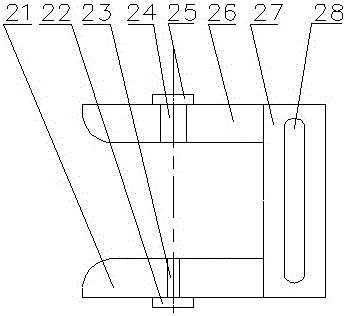

[0012] Embodiment 2: On the basis of Embodiment 1, a detection method of a micro-airflow sand belt position detection device of a wide-band sander, the compressed air gas delivery pipeline 7 inlet end leads to 4-6kg / cm 2 Compressed air, the compressed air is divided into two paths by the tee in the compressed air pipeline 7, one path directly enters the reversing valve 4, and the other path goes to the air blowing pressure regulating valve 1, and the compressed air passes through the air blowing pressure regulating valve 1 into the air Control board 2, the airflow blown out by blowing hole 23 in air control board 2 blows into the air connection hole 24 on the opposite side to receive the air flow, because the aperture of air blowing hole 23 is smaller than the diameter of air connection hole 24, the micro airflow received by air connection hole 24 flows in Air pressure amplifier 3, the air flow is amplified by the air pressure amplifier 3 to force the thimble in the air pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com