Protective film

A protective film, anti-shock technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., to achieve the effect of preventing crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

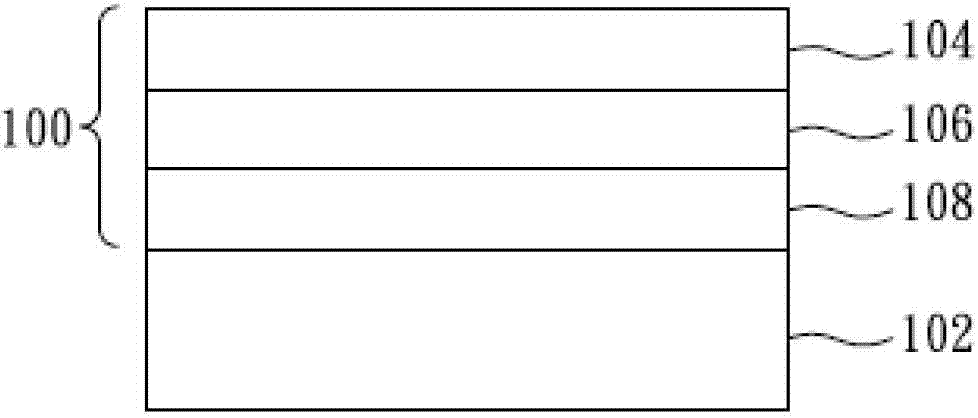

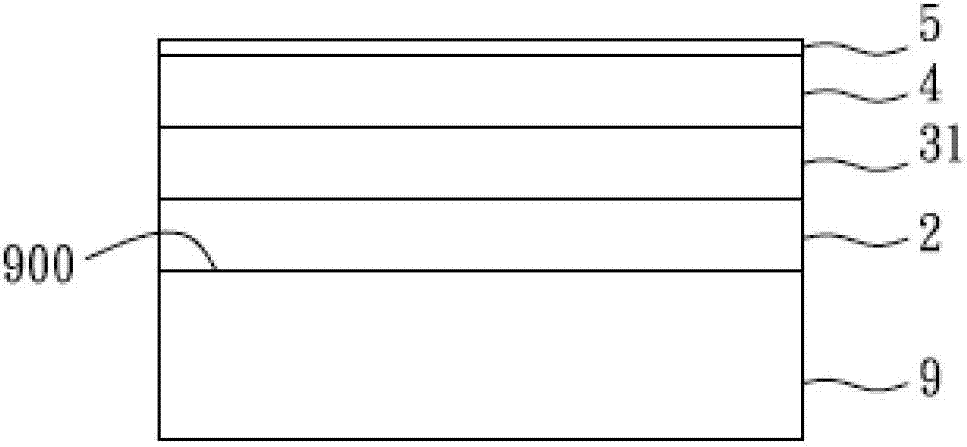

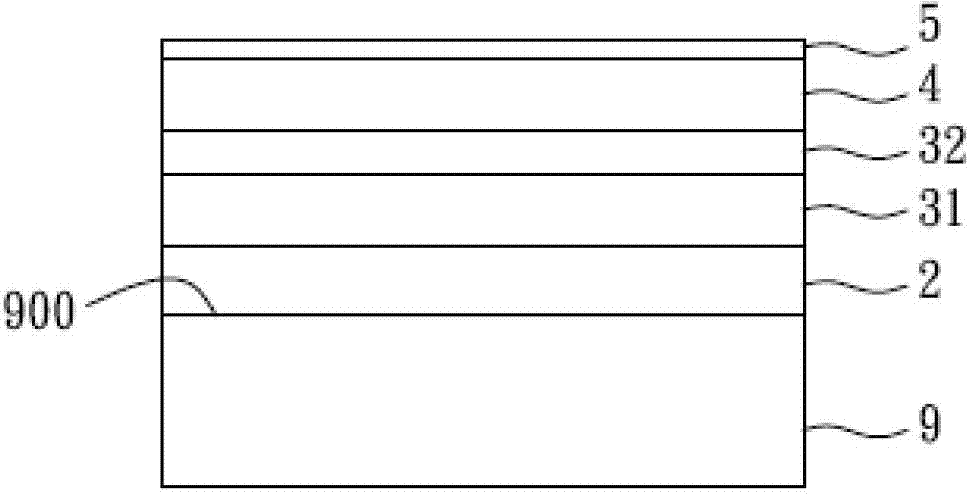

[0030] refer to figure 2 A first preferred embodiment of the protective film of the present invention comprises a layer of adhesive layer 2 for sticking on the surface 900 of a glass 9, an impact-resistant layer 31 on the adhesive layer 2, a layer of The support layer 4 connected to the impact-resistant layer 31, and a layer of scratch-resistant layer 5 located on the surface of the support layer 4, and the light transmittance of the protective film of the present invention for visible light (visible light) is greater than 85%, more preferably The light transmittance is greater than 90%, and the haze is less than 7%; especially when the glass 9 is used for touch screens or window glass of electronic products, good optical properties will make the protective film of the present invention stick It will not hinder the chromaticity of the user's viewing of the scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com