Anti-shock and power-wasting uniform section joist steel and framed girder comprising same

A technology of I-beam and constant section, applied in the direction of joists, girders, truss beams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

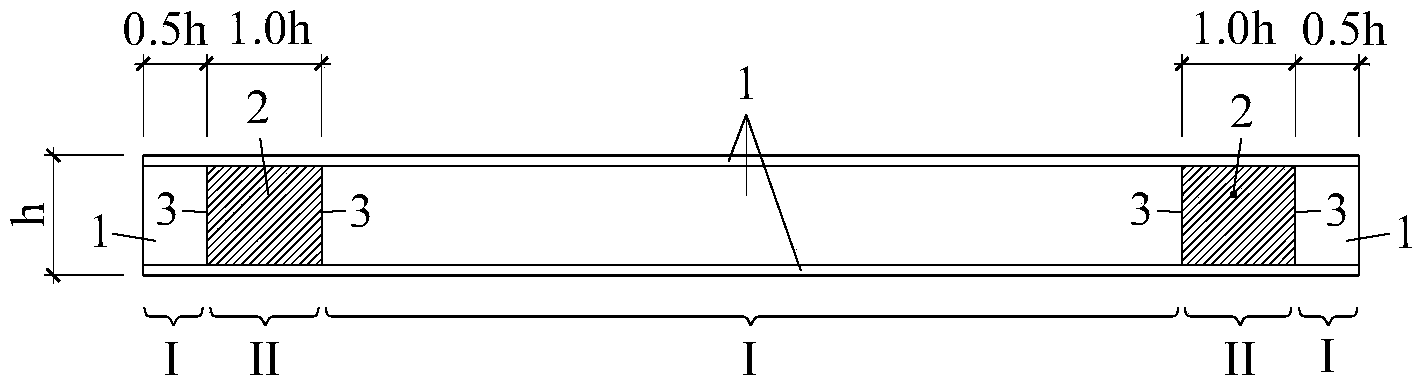

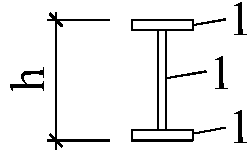

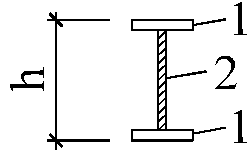

[0033] see figure 1 , 2 , 3, a kind of anti-seismic energy consumption equal-section combined I-steel frame beam, adopts the equal-section combined I-steel of anti-seismic energy consumption, I-steel comprises flange and web, the section height h=600mm of I-steel, The web includes three sections of the first web I and two sections of the second web II that are connected side by side in sequence. The first web I and the flange are made of high-yield point steel 1, and the second web II is made of low-yield steel. Made of point steel 2, the upper and lower ends of the first web I and the second web II are connected to the wing plate, the length of the second web II is 1.0h=600mm, the distance from the second web II to the beam end The distance is 0.5h=300mm. The yield strength of low yield point steel 2 is 235N / mm 2 , the yield strength of high yield point steel 1 is 345N / mm 2 , the ratio of the two is 0.68, which is between 0.5 and 0.7. The web low yield point steel mater...

Embodiment 2

[0035] see figure 1 , 2 , 3, a kind of anti-seismic and energy-dissipating equal-section combined I-steel frame beam, adopting anti-seismic and energy-dissipating equal-section combined I-steel, I-steel includes flange and web, I-steel section height h=480mm, web The plate consists of three sections of the first web I and two sections of the second web II that are connected together in sequence. The first web I and the flange are made of high-yield point steel 1, and the second web II is made of low-yield point steel. Made of steel 2, the upper and lower ends of the first web I and the second web II are connected to the wing plate, the length of the second web II is 1.0h=480mm, the distance from the second web II to the beam end It is 0.5h=240mm. The yield strength of low yield point steel 2 is 155N / mm 2 , the yield strength of high yield point steel 1 is 235N / mm 2 , the ratio of the two is 0.66, which is between 0.5 and 0.7. The web low yield point steel material 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com