Metal section dual glue injection thermal insulation method and component

A metal profile, double-injection technology, which is applied in building components, building structures, windows/doors, etc. demand, processing convenience, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

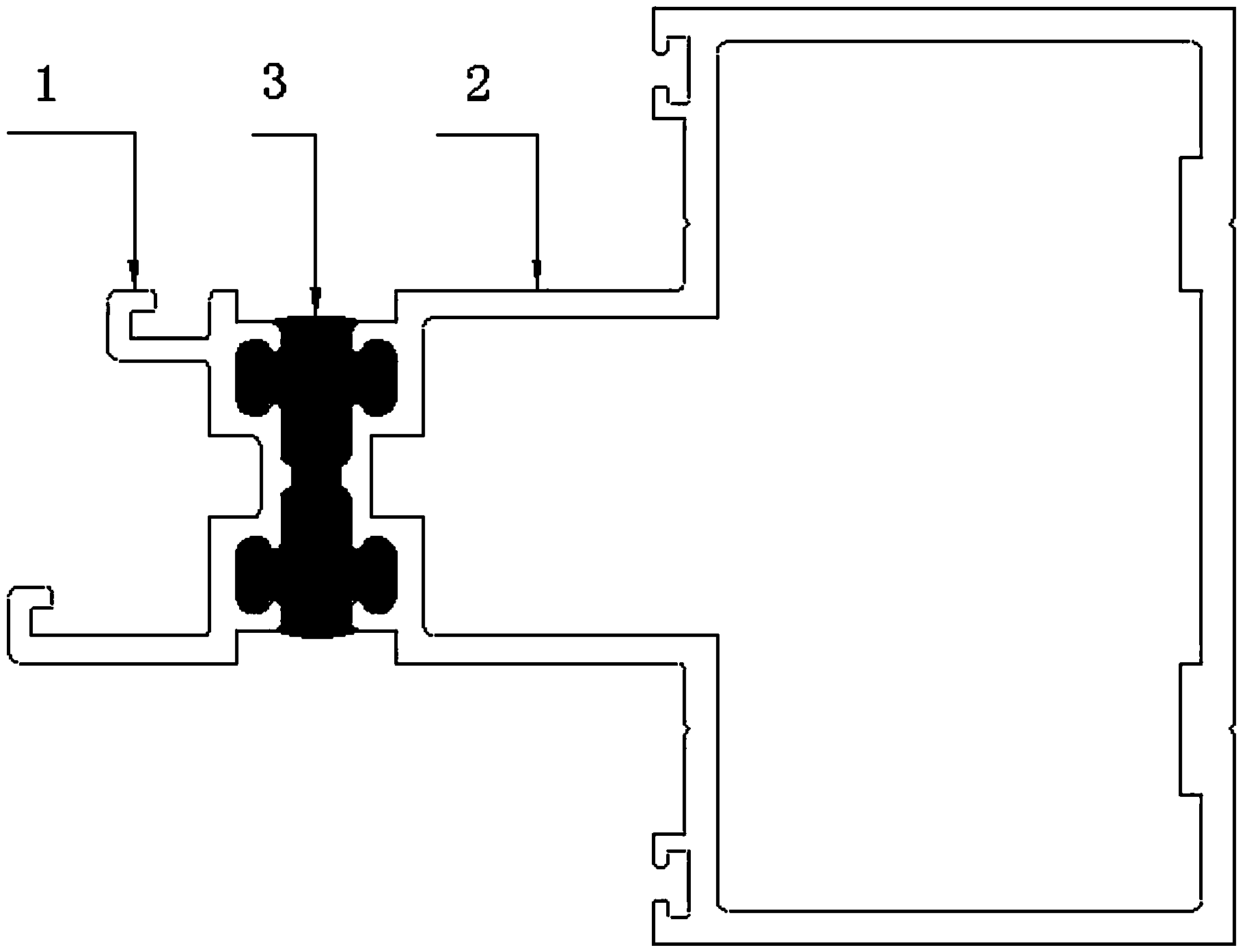

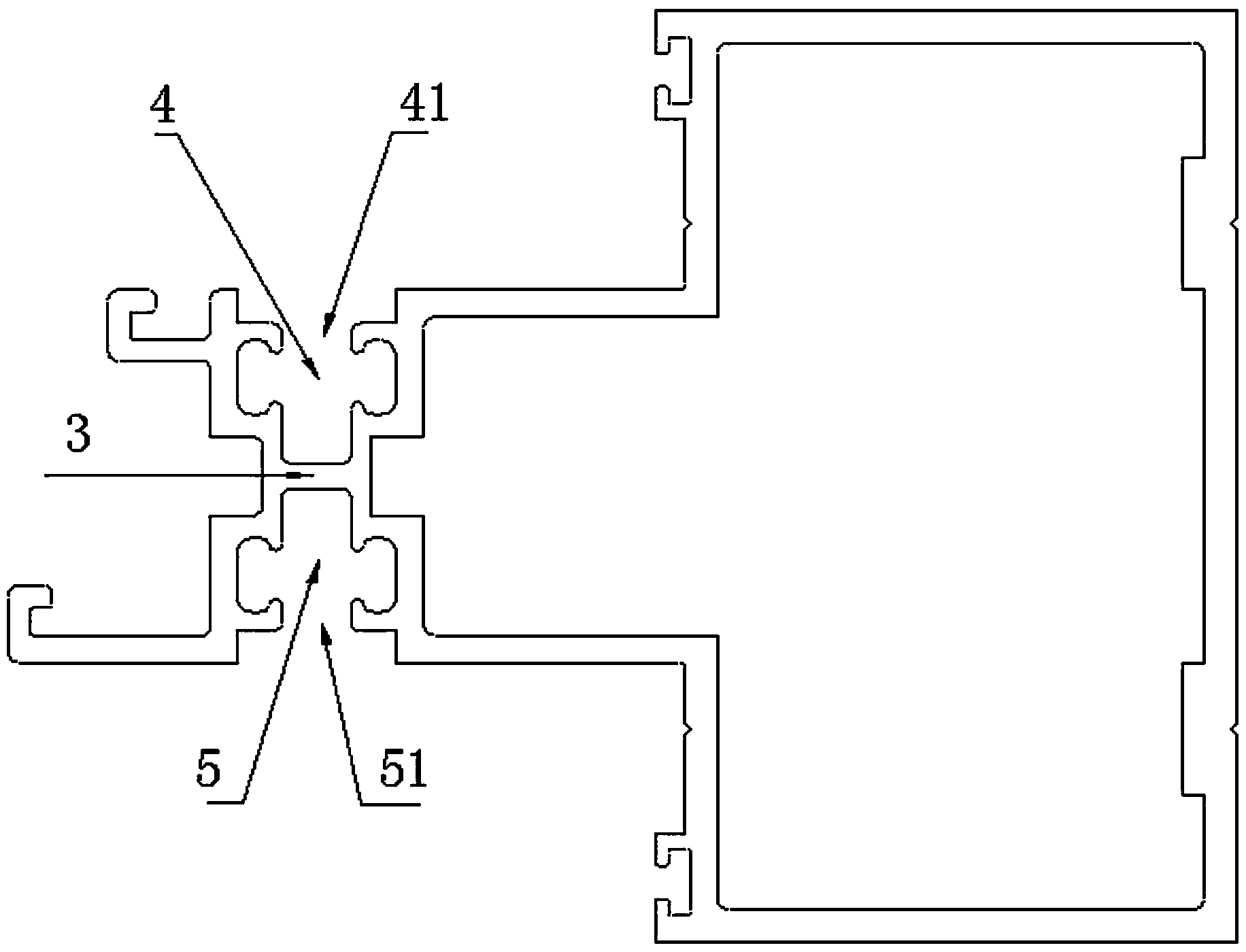

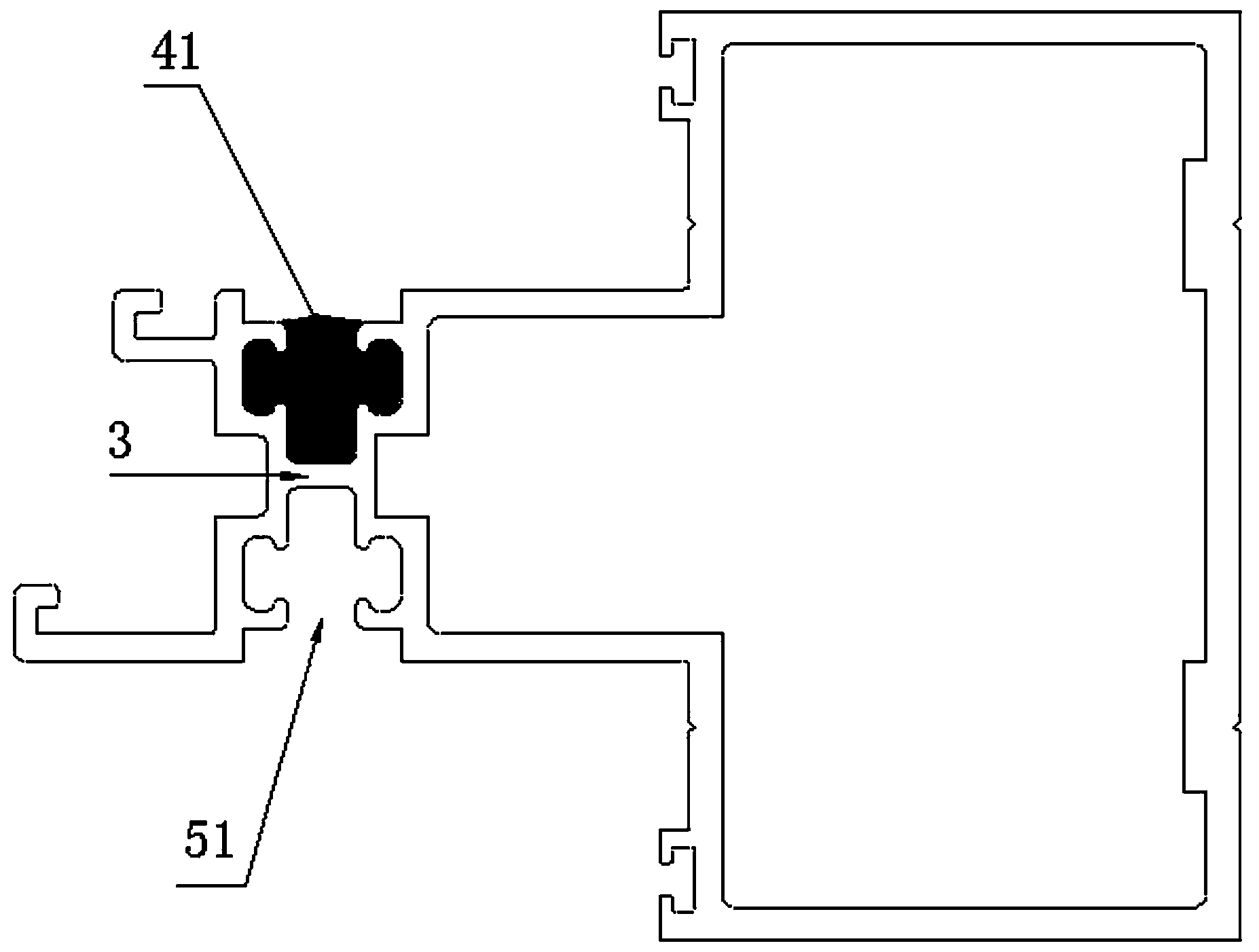

[0022] see Figure 2 to Figure 5 , a metal profile double injection glue heat insulation method is to use heat insulating glue (with the prior art) 3 to connect the first profile 1 and the second profile 2 into one, it is characterized in that it includes the following steps:

[0023] 1) First, the first profile 1 and the second profile 2 are connected through the connecting rib 3 to form an integral profile, and the two sides of the connecting rib 3 are respectively provided with the first heat-insulating glue connection cavity 4 and the second heat-insulating glue connection Cavity 5, first glue injection notch 41 and second glue injection notch 51 are respectively provided on the outside of first heat insulation glue connection cavity 4 and second heat insulation glue connection cavity 5;

[0024] 2) Inject heat insulating glue in the first glue injection slot 41, so that the heat insulating glue fills the first heat insulating glue connection cavity 4;

[0025] 3) Afte...

Embodiment 1

[0030] see figure 1 , the metal profile member made by the metal profile double injection glue heat insulation method is characterized in that it includes two parallel first profile 1 and second profile 2, the opposite side of the first profile 1 and the second profile 2, Each is provided with at least two corresponding slots that can form two connected heat-insulation glue connection cavities (two independent heat-insulation glue connection cavities can be formed before the middle connecting rib is cut off, such as figure 2 The first heat-insulating glue connects the cavity 4 and the second heat-insulating glue connects the cavity 5, and the two cavities are connected after cutting off), the first profile 1 and the second profile 2 pass through the connected heat-insulating cavity filled with the two cavities The glue is tightly connected and spaced apart, and a first glue injection notch 41 and a second glue injection notch 51 are respectively provided on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com