Multi-shoe integral brake

A brake and integral technology, which is applied in the direction of mechanically driven drum brakes, brake actuators, gear transmission mechanisms, etc., can solve the problems of increasing the power consumption of the pusher, increasing the temperature of the brake pad, and small frictional contact area. problem, to achieve the effect of increasing the braking friction area, increasing the braking torque, and good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment.

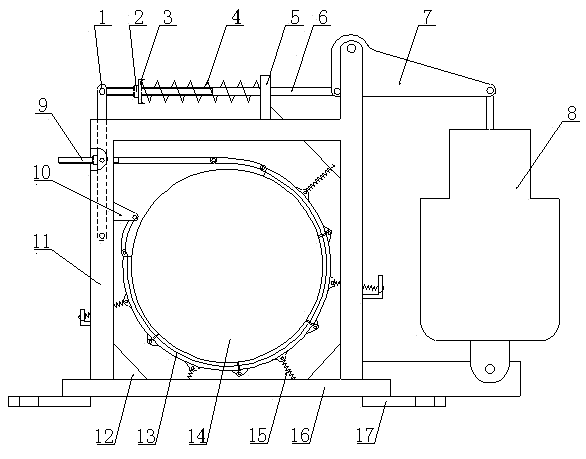

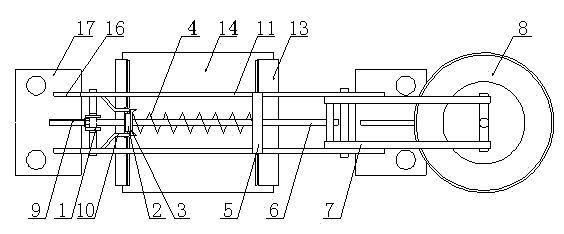

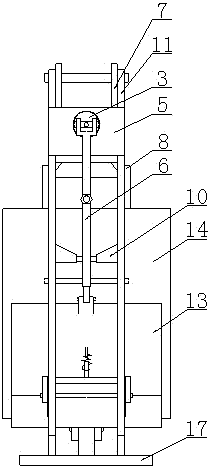

[0024] Depend on Figures 1 to 5 It can be seen that the multi-watt integral brake includes a brake shoe 21, a brake pad 20, a base 16, an electric pusher 8 and a top pressure spring 4, a frame 11 and a pusher are arranged on the base, and a rocker arm is arranged on the frame. 7. The pull rod mechanism composed of push-pull rod 6, connecting rod 9 and lever 1, one end of the pull rod mechanism is connected to the pusher, and the other end is connected to the frame; a brake chain belt 13 formed by five brake tiles is arranged in the frame to make The dynamic chain belt is formed into a circle and floats on the surface of the brake drum 14. One end of the brake chain belt is connected to the frame, and the other end is connected to the connecting rod. Shake to drive the brake chain to move.

[0025] Depend on figure 1 , 6 It can be seen that the pull rod mechanism is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com