LED heat radiator based on heat pipe technology

A kind of LED heat sink technology, which is applied in semiconductor devices of light-emitting elements, lighting and heating equipment, cooling/heating devices of lighting devices, etc., can solve the problem of large temperature gradient, low heat conduction efficiency, and slow start of heat dissipation of radiators, etc. problem, to achieve the effect of reducing thermal gradient, rapid heat dissipation, and fast start of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention.

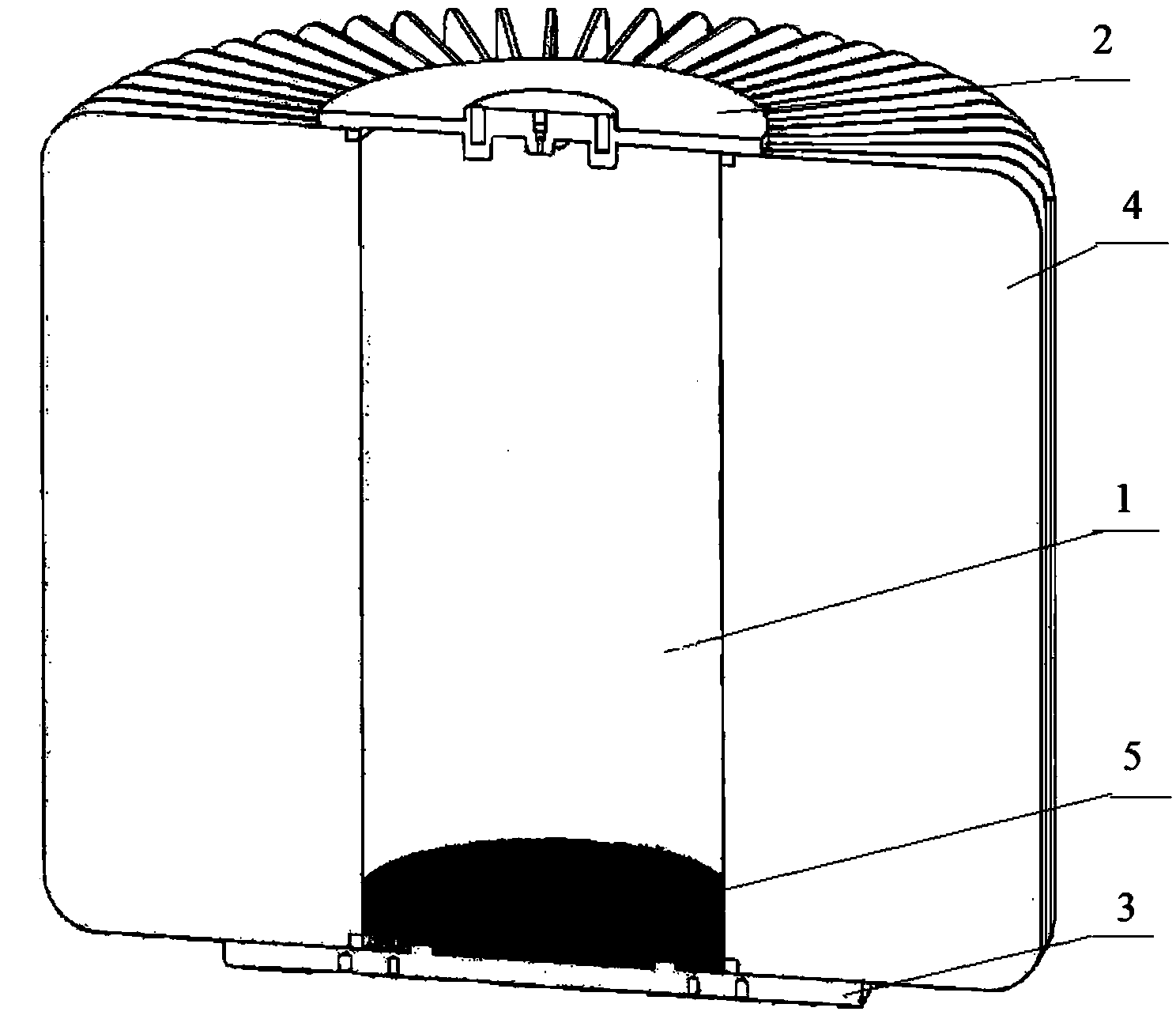

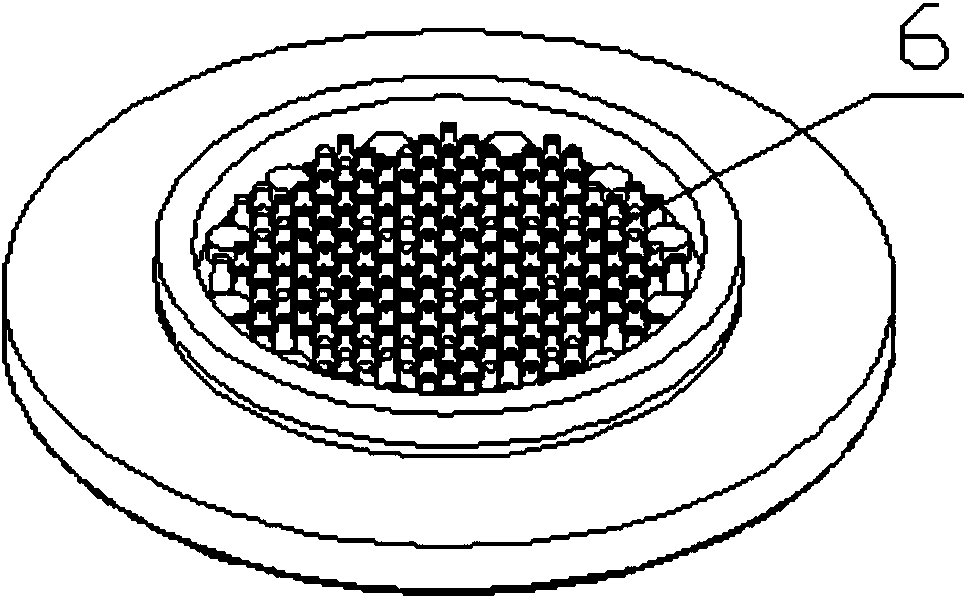

[0023] An LED heat sink based on heat pipe technology, including a gravity heat pipe arranged in the center and sunflower-shaped heat dissipation fins 4 arranged around the gravity heat pipe. The gravity heat pipe includes a through pipe 1 in the middle, an upper cover 2 and a bottom cover 3. The through-pipe 1 in the middle is welded together with the upper cover 2 and the bottom cover 3, sealed to form a vacuum, the middle is filled with a refrigerant 5, the heat dissipation fins 4 are arranged around the through-pipe 1, and the bottom cover 3 is The part of the surface located in the through pipe is provided with evenly distributed multi-point protruding groove structure 6, the upper cover 2 has a sealing hole 7 in the middle, and the bottom of the bottom cover 3 is connected with the LED lamp.

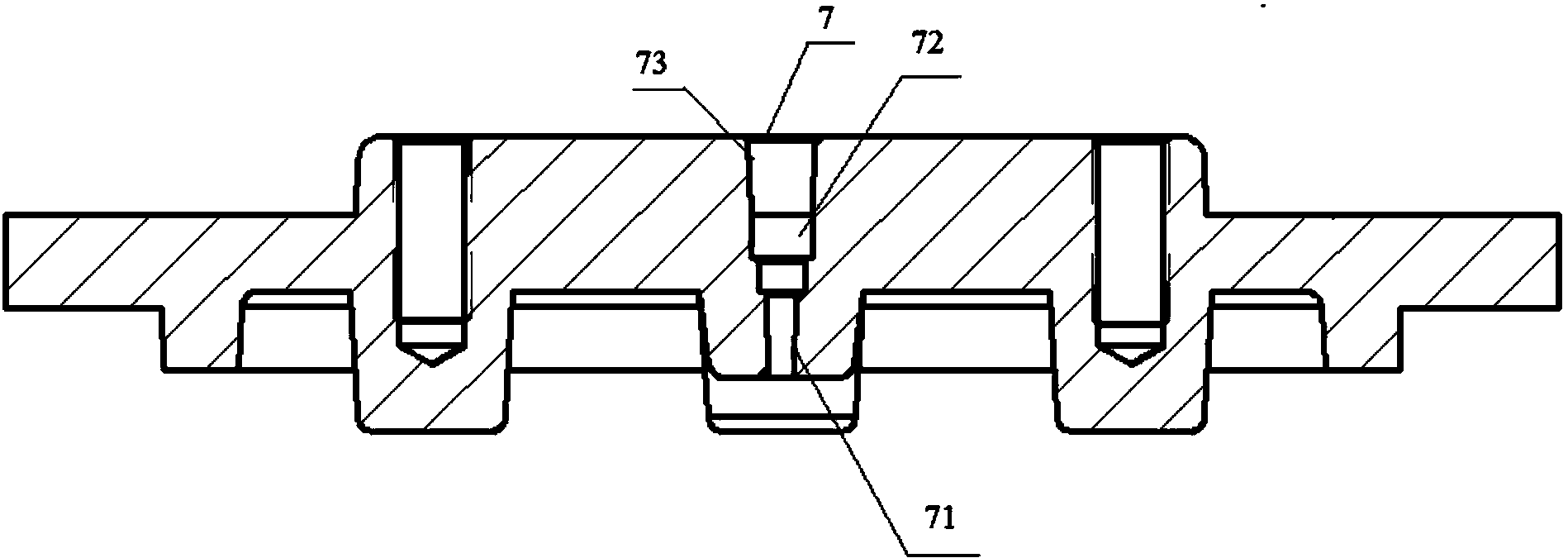

[0024] The sealing hole 7 includes a lower inverted tapered hole section 71 , a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com