Novel evaporative condenser

An evaporative condenser and condenser technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems that cannot meet the needs of modern customers, require a large amount of condensing medium, and cannot be miniaturized, etc. problems, to achieve the effect of reducing power, reducing system circulating water and air flow, and convenient cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

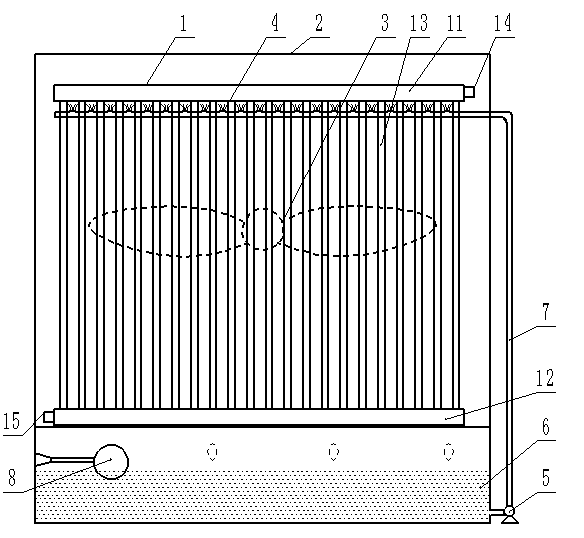

[0012] The simple structural diagram of this embodiment is as follows: figure 1 Shown, the present invention will be further described below in conjunction with accompanying drawing. The main structure of the system device involved in the realization of the present invention consists of a heat exchanger (1), a gas collecting pipe (11), a liquid collecting pipe (12), and an intermediate flat tube between the gas collecting pipe (11) and the liquid collecting pipe (12). (13), medium inlet (14), medium outlet (15), condenser shell (2), fan (3), spray water device (4), water pump (5), water collection tank (6), pipe Road (7) and float valve (8) form. The implementation process of the present invention is as follows: the refrigerant steam flows into the middle flat tube (13) of the heat exchanger from the medium inlet (14) of the heat exchanger through the gas collector (11), and is sprayed with the spray water device (4) The cold water coming out is subjected to heat exchange, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com