Hydraulic tensile testing machine for connection devices in mine workshop

A technology of tensile testing machine and connecting device, which is applied in the direction of vehicle testing, measuring devices, testing of mechanical parts, etc., can solve problems such as difficulty, and achieve the effects of ensuring safety performance, simple structure, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

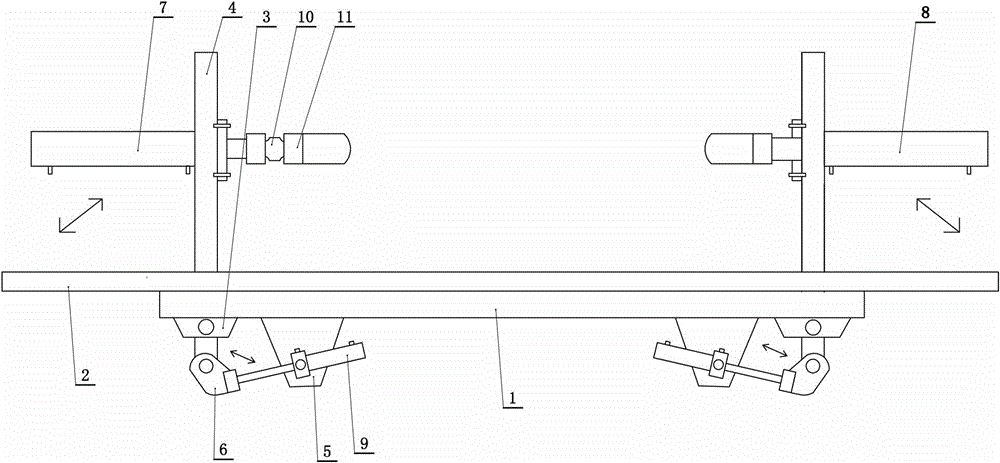

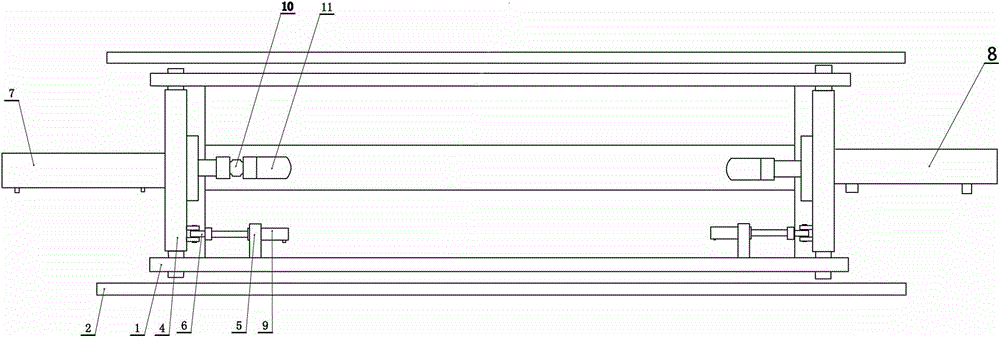

[0019] A hydraulic tensile testing machine for a mine workshop connection device, characterized in that it includes a mine car track 2, a test bench frame 1, a motion mechanism and a hydraulic system;

[0020] The test bench frame 1 is in the middle of the mine car track 2, the horizontal height of the test bench frame 1 is lower than the height of the mine car track 2, and the hydraulic system fixing seat 5 is arranged under the two ends of the test bench frame 1;

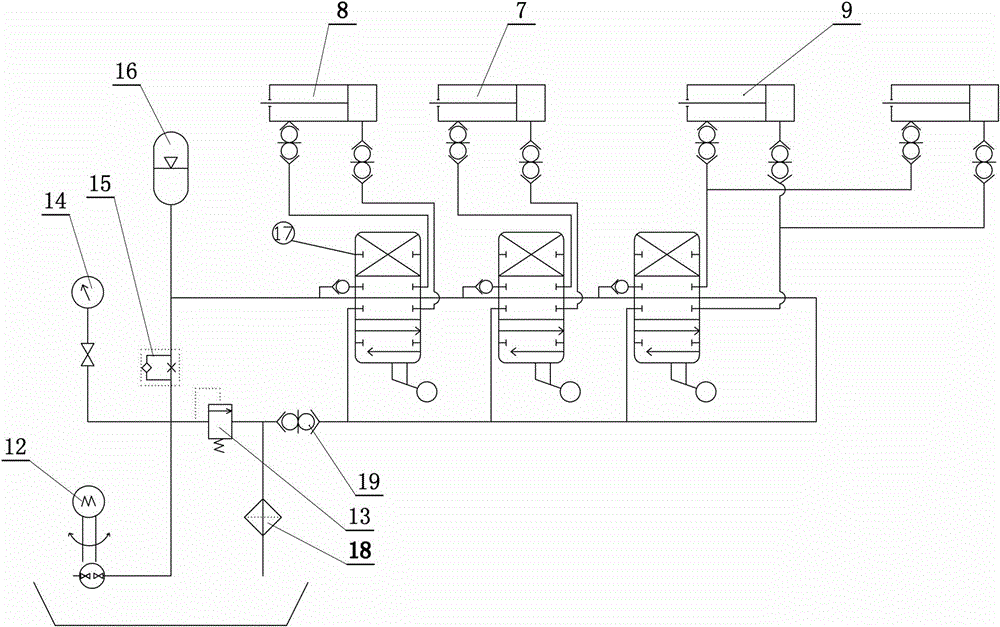

[0021] The motion mechanism includes a pair of traction levers 4, a large hydraulic cylinder 8, a medium hydraulic cylinder 7, two small hydraulic cylinders 9 and a plurality of connecting pins 6, and the lower fulcrum of the traction lever 4 is rotated and connected. On the support beam 3 of the test bench frame 1, the large hydraulic cylinder 8 is arranged on the upper part of the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com