Car strength and fatigue early-warning method and system

A car fatigue technology, which is applied in the field of car reliability and durability testing, can solve problems such as potential safety hazards and resource waste, and achieve the effect of avoiding resource waste and reducing car fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

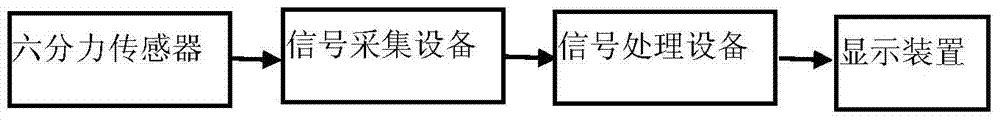

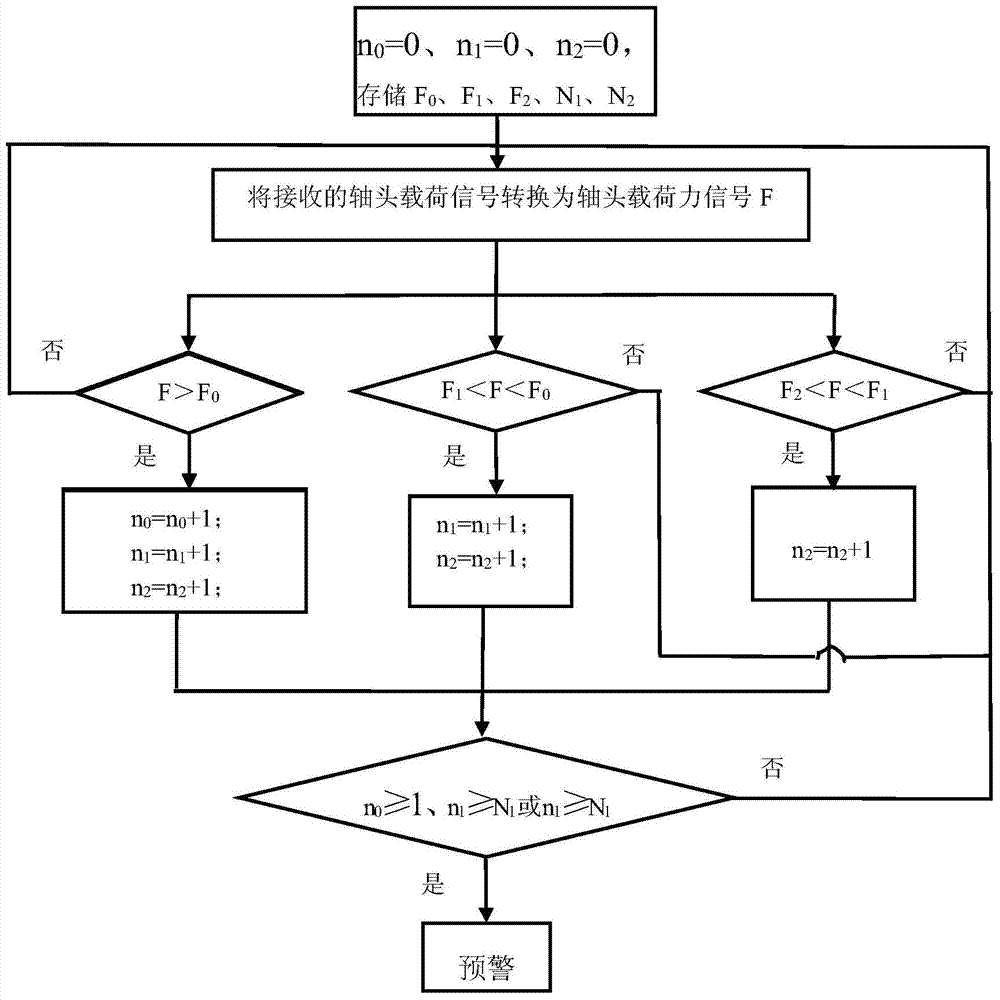

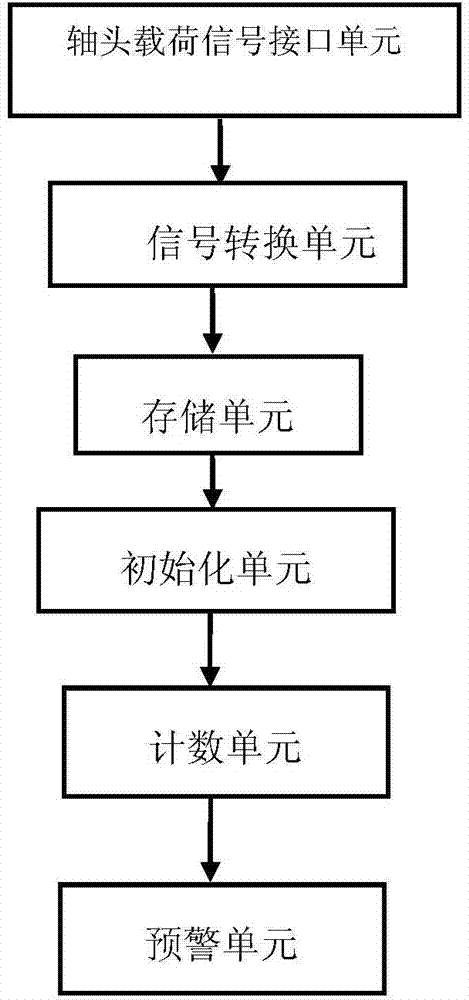

[0025] Such as figure 1 As shown, the car strength and fatigue early warning device of the present invention includes a six-component force sensor, signal acquisition equipment, signal processing equipment and a display device. The six-component force sensor is installed on the four wheel axle heads, and the signal processing device is an on-board computer (ECU); the output of the six-component force sensor is connected to the ECU through the signal acquisition device. The signal acquisition device can use an A / D conversion chip to convert the analog signal of the shaft head load output by the six-component force sensor into a digital signal acceptable to the signal processing device; the signal acquisition device can also use a level conversion chip to convert the The digital signal of the shaft head load output by the six-component force sensor is converted into a shaft head load level signal acceptable to the signal processing equipment. The signal processing equipment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com