Paraffin finishing and paraffin block cutting surface sealing device of paraffin embedding box

A paraffin-embedding and wax-repairing technology is applied in the field of medical devices, which can solve the problems of laboriousness, low efficiency, delayed production time, etc., and achieve the effects of improving wax removal efficiency, fast heating speed and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

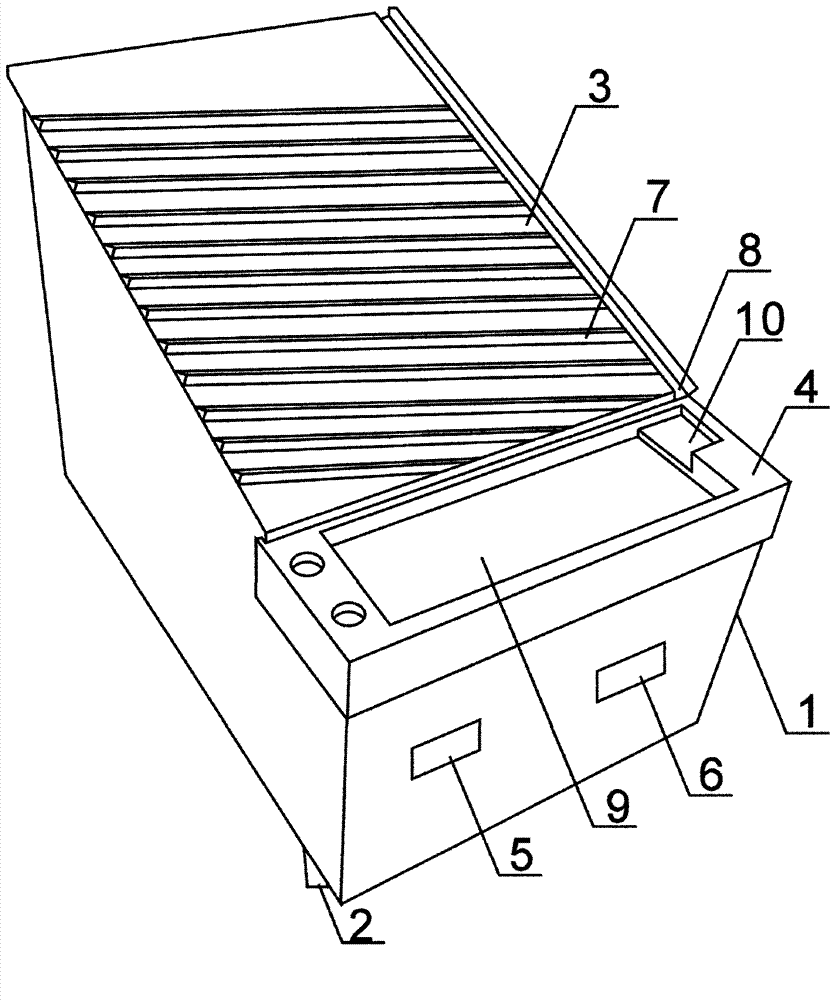

[0012] figure 1 The most preferred embodiment of the present invention is shown. The paraffin embedding box wax sealing instrument of the present invention has a main body 1, and the bottom of the main body 1 is provided with 4 legs 2, and on the top platform of the main body 1 There is a wax repairing heating plate 3 and a wax sealing heating plate 4 inclined to the wax repairing heating plate 3. The installation angle between the wax repairing heating plate 3 and the wax sealing heating plate 4 is 40 degrees. The outer wall of the main body There is a wax repair heating plate switch 5 connected to the wax repair heating plate 3 and a wax sealing heating plate switch 6 connected to the wax sealing heating plate 4. The wax repair heating plate 3 is obliquely provided with a plurality of parallel pointed Angle edge 7, the angle of angle edge 7 is 10~80 degree, has the guiding groove 8 that can divert wax liquid on the side of many sharp angle edge 7; The sealing wax heating pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com