Ultraviolet-proof cable with high temperature resistance

An anti-ultraviolet and high-temperature-resistant technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of not having anti-ultraviolet rays, etc., and achieve the effects of excellent anti-interference performance, superior electrical performance, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

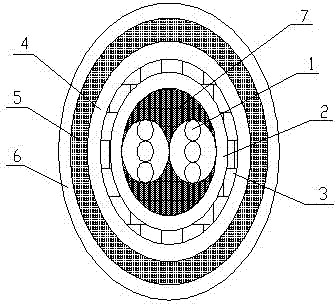

[0008] A high-temperature-resistant and UV-resistant cable, which is composed of a conductor 1, an insulating layer 2, a steel tape armor layer 5 and an outer sheath 6, and the outside of the conductor 1 is formed by extruding the shielding layer 3 and the insulating layer 2; The conductor 1 is provided with three wire cores; the two groups of three wire cores constitute the cable core; the high temperature resistant glass filament is arranged between the cable core and the insulating layer 2 to form the filling layer 7; the shielding layer 3 is from outside to inside The outer sheath 6, the steel tape armor layer 5 and the high flame-retardant wave fiber tape are extruded around the cladding layer 4; the wire core is made of twisted strands of tinned copper wires; the steel tape armor layer The steel strip braiding density of 5 is not less than 88%; the material of the outer sheath 6 is anti-ultraviolet plastic.

[0009] Although the specific mode of the present invention has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com