Electrolyte for aluminum electrolytic capacitor

An aluminum electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of low electrical conductivity, low solubility, and large electrical conductivity drop, and achieve long capacitor life, good thermal stability, and low temperature. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

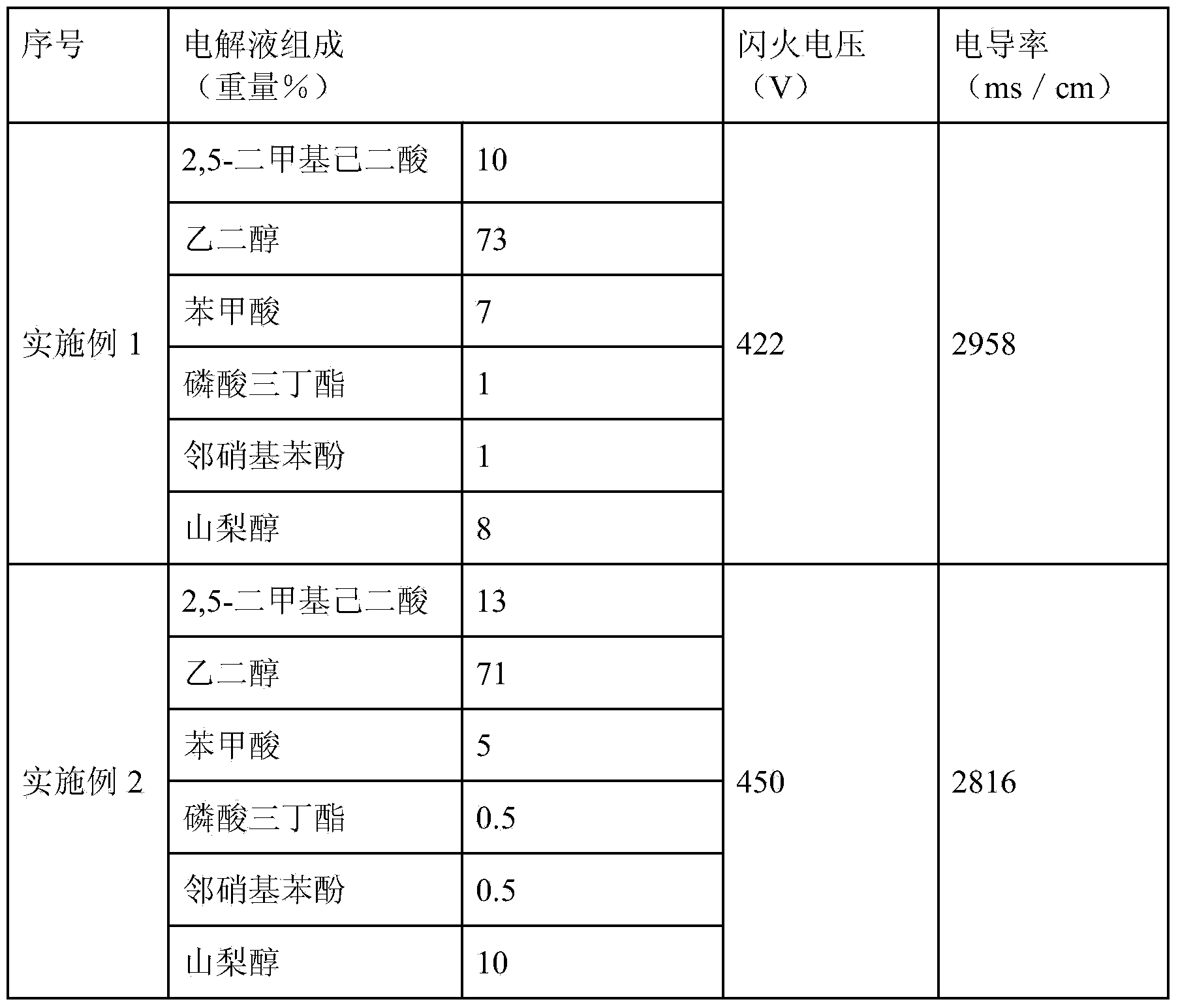

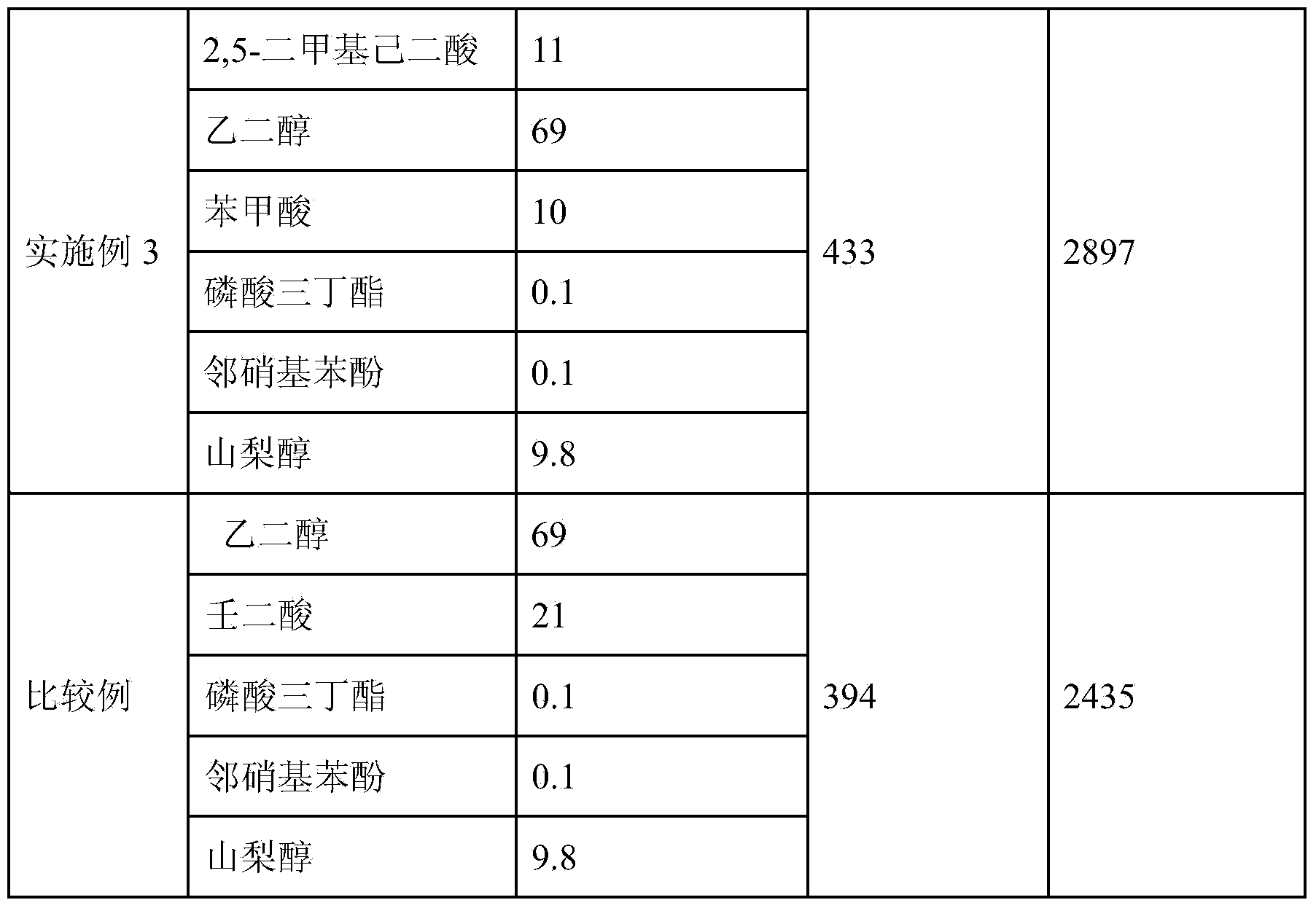

[0019] To prepare the electrolyte of the present invention, see Table 1.

[0020] Table 1 Electrolyte formula table

[0021]

[0022]

Embodiment 2

[0024] To prepare the electrolyte of the present invention, see Table 1.

[0025] Comparing the electrolyte of the present invention with the traditional electrolyte, the results are shown in Table 1. It can be seen from Table 1 that the flash voltage and conductivity of the electrolyte prepared with 2,5-dimethyl adipic acid as the electrolyte have been significantly improved, and it is suitable for the preparation of electrolytes above 400V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com