A method and device for matching radio frequency pulse power in a vacuum processing chamber

A radio frequency pulse and vacuum processing technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of high cost, uncontrollable load power, complex principle of automatic matching device, etc., and achieve the effect of low cost and controllable power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Those skilled in the art understand that those skilled in the art can implement the variation example in combination with the prior art and the foregoing embodiments, which will not be repeated here. Such variations do not affect the essence of the present invention, and will not be repeated here.

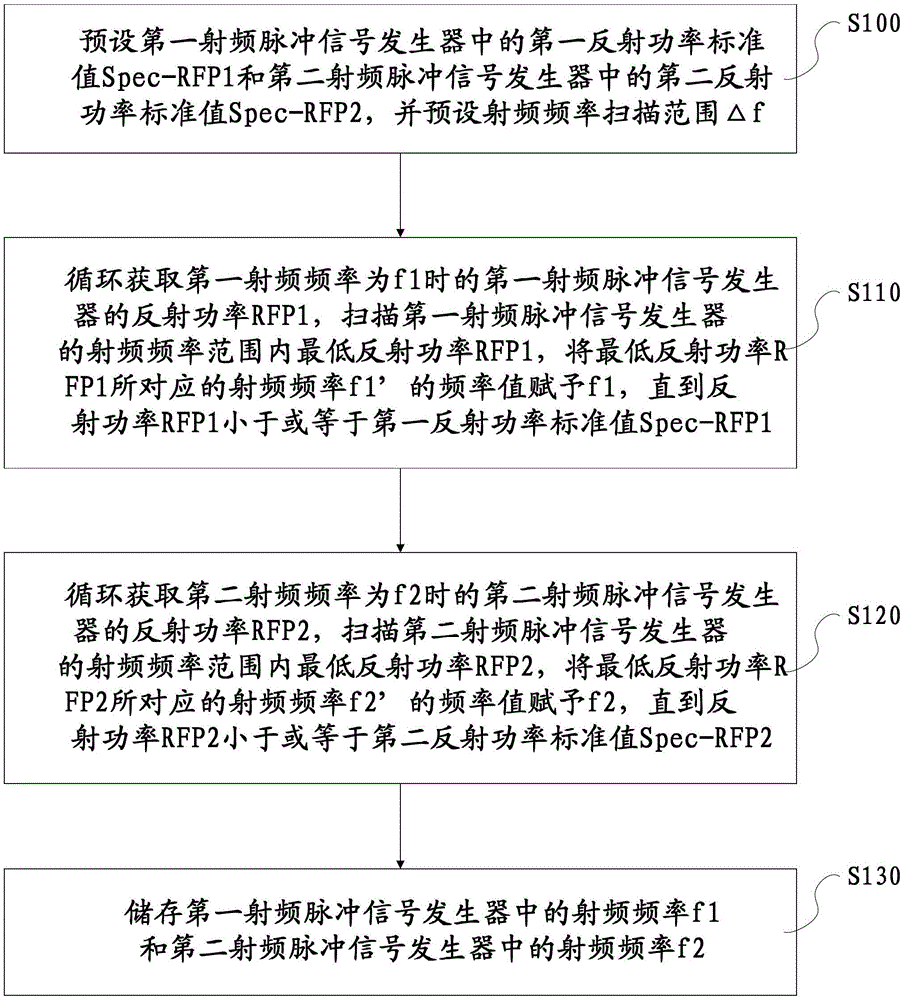

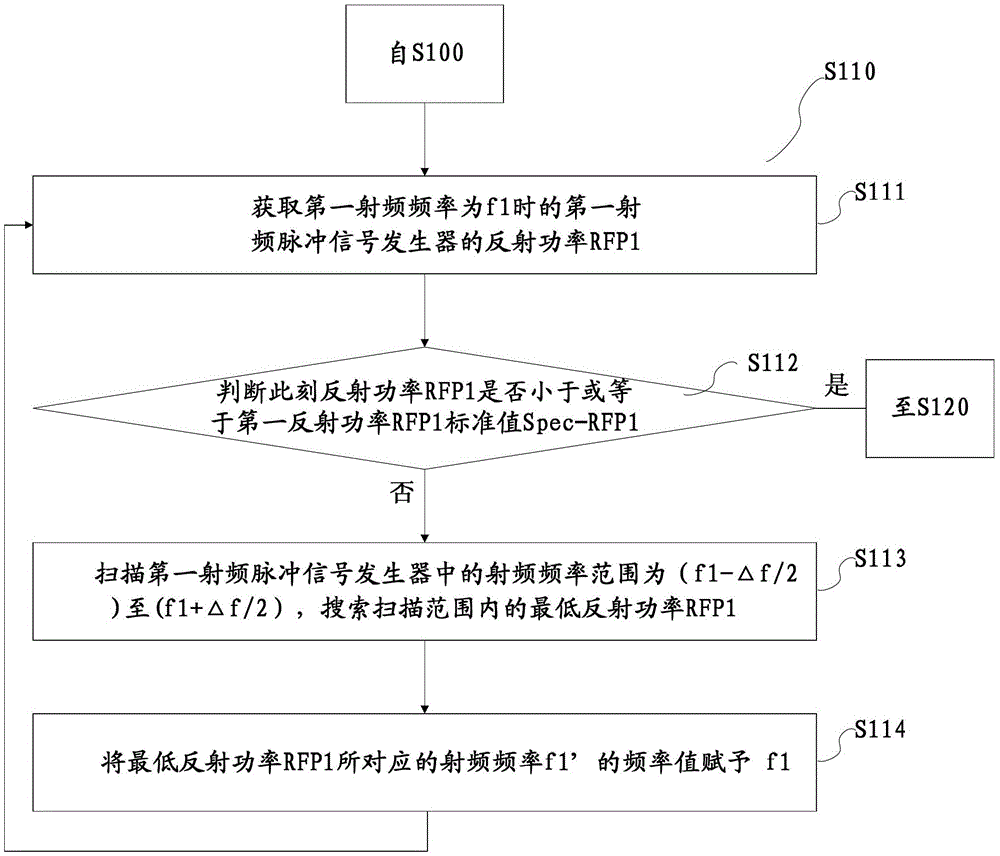

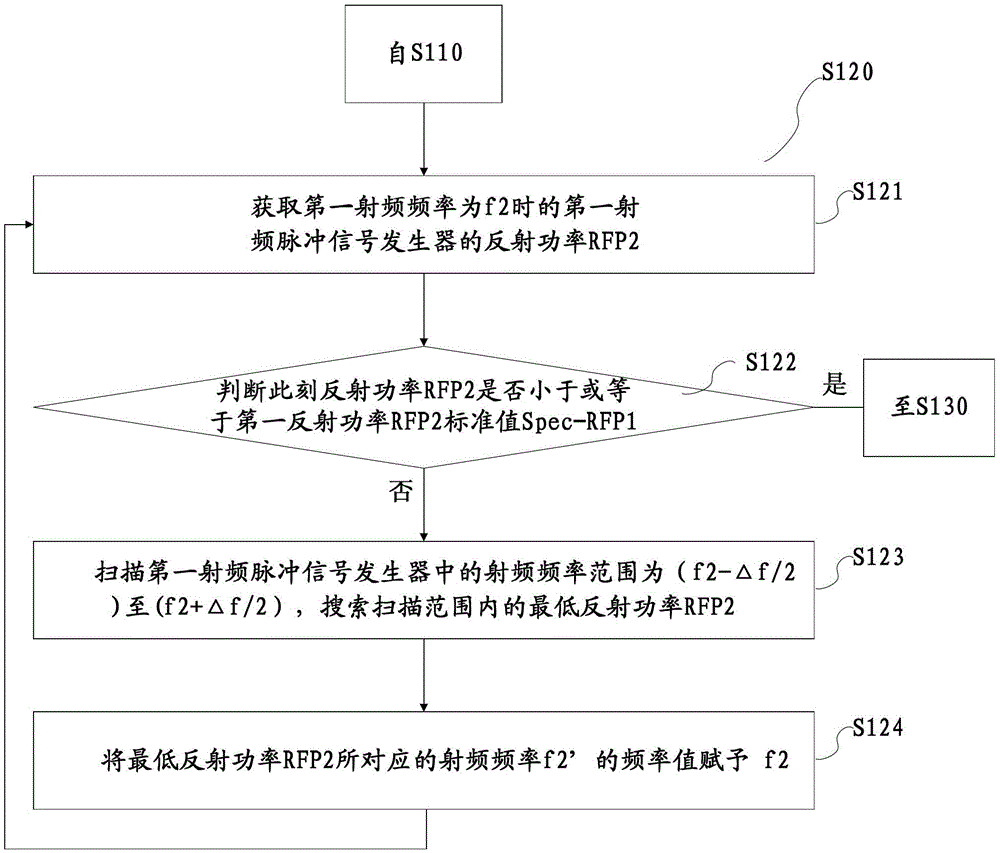

[0059] figure 1 A flowchart showing a method for matching radio frequency pulse power of a vacuum processing chamber according to a specific embodiment of the present invention. Such as figure 1 As shown, a method for matching the radio frequency pulse power of a vacuum processing chamber of the present invention, the vacuum processing chamber has two radio frequency pulse signal generators connected to its lower electrode, comprising the following steps:

[0060] S100: preset the first reflected power standard value Spec-RFP1 in the first radio frequency pulse signal generator and the second reflected power standard value Spec-RFP2 in the second radio frequency pulse sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com