Anti-slip strategy for pure electric buses driven by permanent magnet motors on ramps

A technology of permanent magnet motor and ramp start, which is applied in the direction of electric vehicles, electric vehicle charging technology, control drive, etc. It can solve the problems of heat damage of one-phase power module, unbalanced three-phase current of motor, and inability to use for a long time. Achieve the effect of ensuring normal and reliable operation and avoiding stalled state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The anti-skid strategy of the pure electric bus ramp driven by the permanent magnet motor of the present invention comprises the following steps:

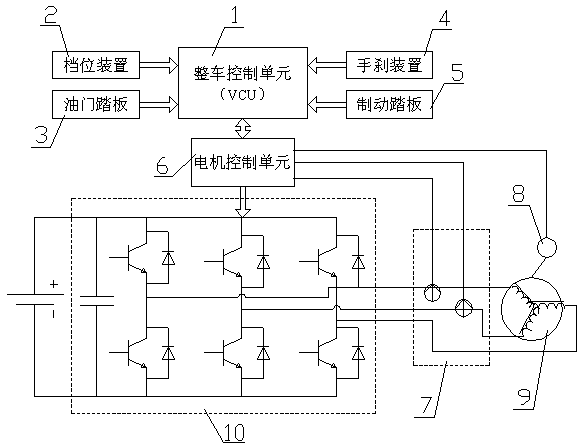

[0017] Step 1, such as figure 1 As shown, the vehicle control unit 1 collects the status information of the gear device 2, the accelerator pedal 3, the handbrake device 4 and the brake pedal 5, and communicates and exchanges information with the motor control unit 6 through the CAN bus, and the motor control unit 6 collects the current sensor 7 and the information of the resolver 8, the current sensor 7 and the resolver 8 detect the operating current and rotation position of the permanent magnet motor 9, and the motor control unit 6 performs double closed-loop power control on the speed and current of the permanent magnet motor 9 through the power module 10;

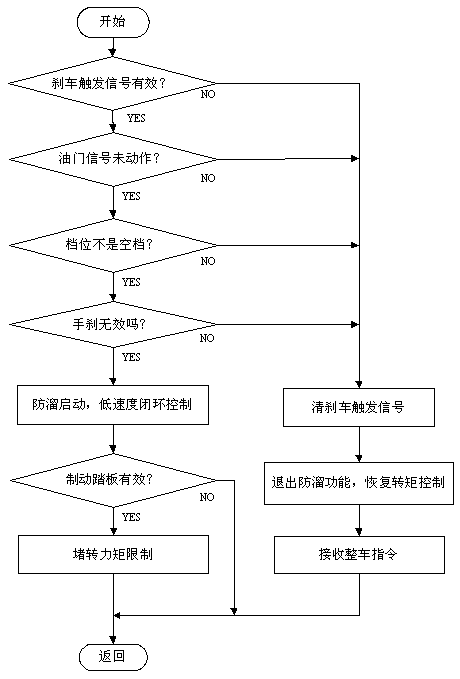

[0018] Step two, such as figure 2 As shown, when the brake pedal has been stepped on and the speed of the permanent magnet motor is less than 15r / min, and this state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com