Control method of electric coal boiler control box

A boiler control and control method technology, applied in the direction of heating methods, household heating, space heating and ventilation details, etc., can solve the problems of poor usability, electric shock of passengers, heavy workload, etc., and achieve a hygienic travel and working environment, convenient Effects of maintenance and inspection and workload reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

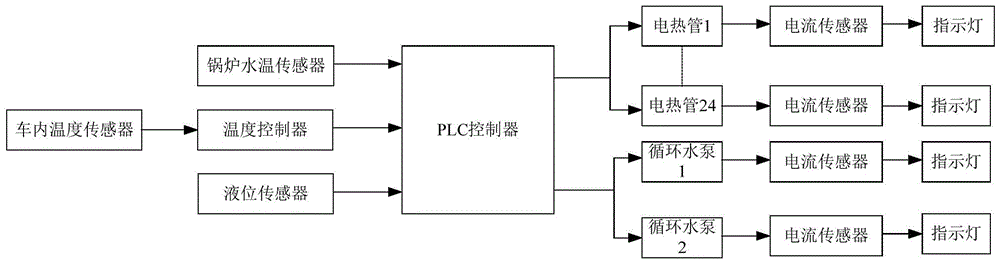

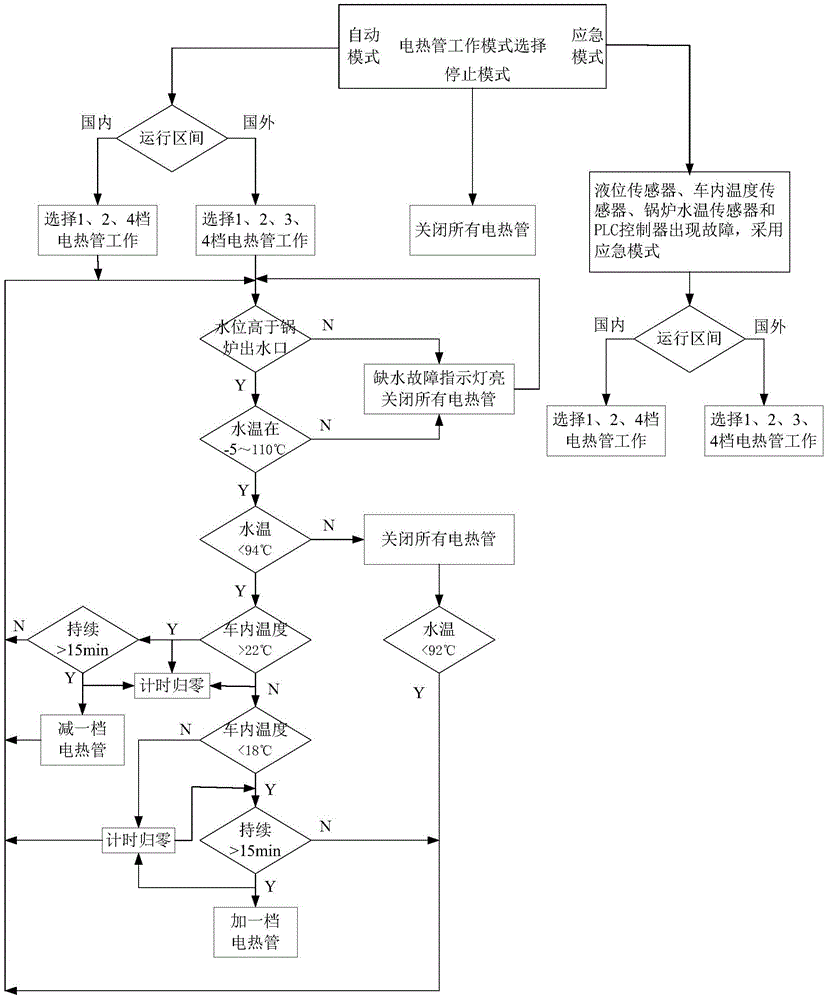

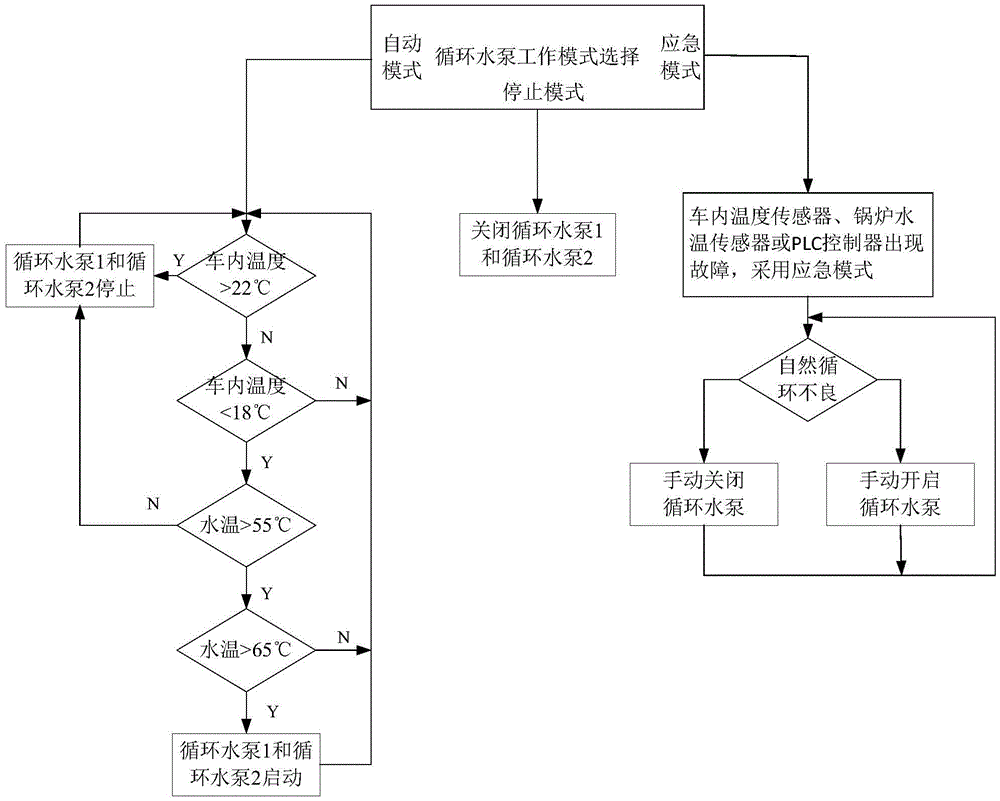

[0039] see figure 1 , an electric coal boiler control box, installed on the back of the boiler, the gap between the boiler and the control box is 50mm, the boiler and the control box are filled with heat insulating material, the control box is mainly composed of the temperature sensor installed inside the car, The boiler water temperature sensor, liquid level sensor, PLC controller, multiple electric heating tubes, circulating water pump, current sensor, indicator light and power circuit that penetrate into the inner side of the furnace wall are composed of the temperature sensor inside the car. The input terminal of the PLC controller is connected, and the start and stop temperature of the electric heating tube is controlled by adjusting the parameters of the temperature controller; the boiler water temperature sensor and the liquid level sensor are connected to the input terminal of the PLC controller, and the boiler water temperature sensor and the liquid level sensor are both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com