Glass fiber reinforced nylon compound used for extrusion molding, and preparation method and application thereof

A technology of extrusion molding and composites, which is applied in the field of polymers, can solve problems such as low melt strength, hollow shrinkage cavity, and deteriorated material properties, and achieve high melt strength, good surface properties, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0072] By the following preparation method, the glass fiber reinforced nylon composite for extrusion molding of Example 1 was prepared:

[0073] Weigh 57 parts of nylon 6, 3 parts of toughening agent EPDM-MAH, 3 parts of LLDPE, 2 parts of chain extender, and 35 parts of glass fiber obtained by vacuum drying at 120°C for 4 hours, and put them into a stirring Mix in the mixer for 3 minutes; add the raw materials mixed in the steps to the twin-screw extruder for processing, and add glass fiber to the third zone of the twin-screw extruder. The processing technology is as follows: the temperature in the first zone of the twin-screw extruder is 120~ 210°C, the temperature of the second zone is 240~300°C, the temperature of the third zone is 240~300°C, the temperature of the fourth zone is 240~300°C, the temperature of the fifth zone is 240~320°C, the temperature of the sixth zone is 240~320°C, the temperature of the machine head is 260~320°C , the pressure is 12~18Mpa.

[0074] Wit...

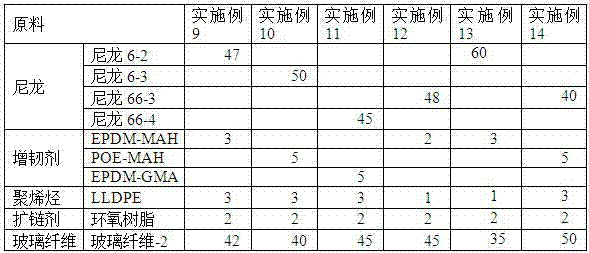

Embodiment 9~14

[0087] By the following preparation method, the glass fiber reinforced nylon composite for extrusion molding of Example 9 was prepared:

[0088] Weigh 47 parts of nylon 6, 3 parts of toughening agent EPDM-MAH, 3 parts of LLDPE, 2 parts of chain extender and 42 parts of glass fiber obtained by vacuum drying at 120°C for 4 hours, and put them into a stirring Mix in the mixer for 3 minutes; add the raw materials mixed in the steps to the twin-screw extruder for processing, and add glass fiber to the third zone of the twin-screw extruder. The processing technology is as follows: the temperature in the first zone of the twin-screw extruder is 120~ 210°C, the temperature of the second zone is 240~300°C, the temperature of the third zone is 240~300°C, the temperature of the fourth zone is 240~300°C, the temperature of the fifth zone is 240~320°C, the temperature of the sixth zone is 240~320°C, the temperature of the machine head is 260~320°C , the pressure is 12~18Mpa.

[0089] Refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com