A multifunctional cloth inspection machine

A cloth inspection machine, multi-functional technology, applied in the inspection of textile materials, textiles and paper making, etc., can solve the problems of low cloth inspection efficiency, unable to meet the large demand for interlining, single function of cloth inspection machine, etc., and achieve good cloth inspection effect , prevent the cloth surface from being too tight, and facilitate roll changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

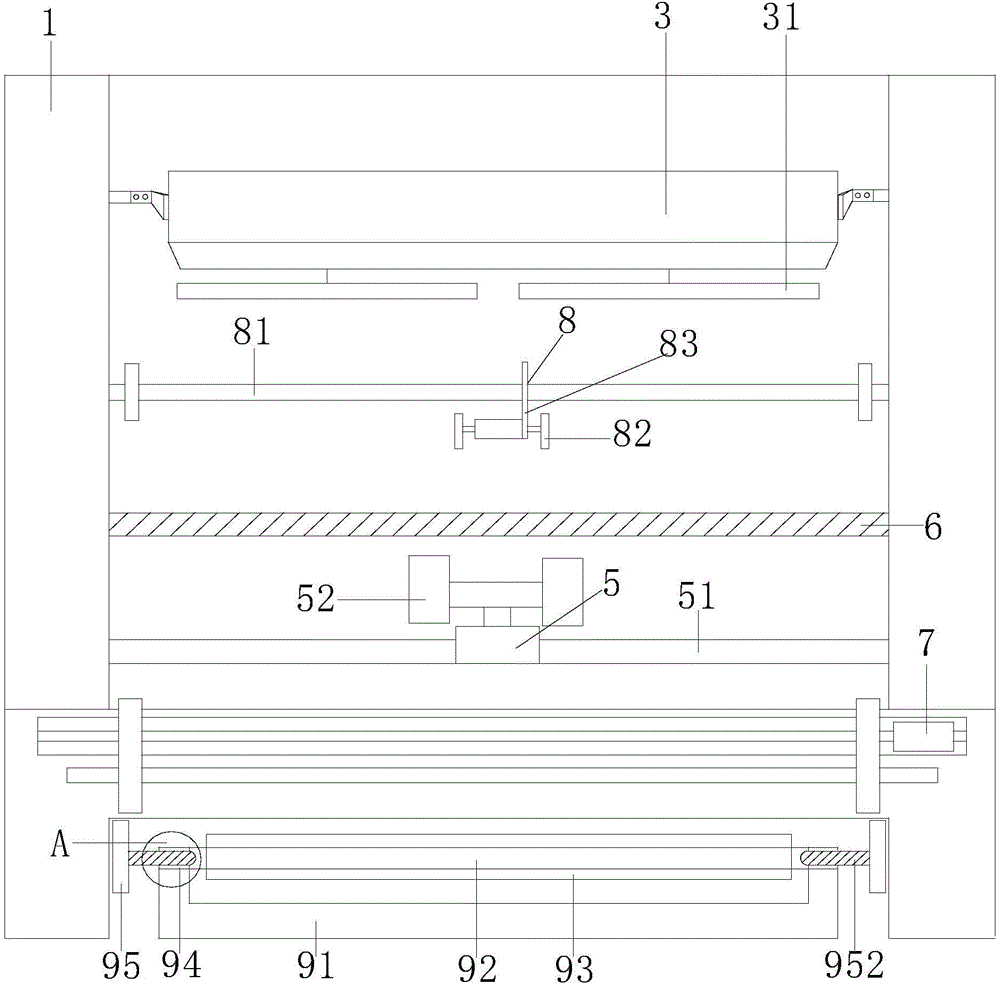

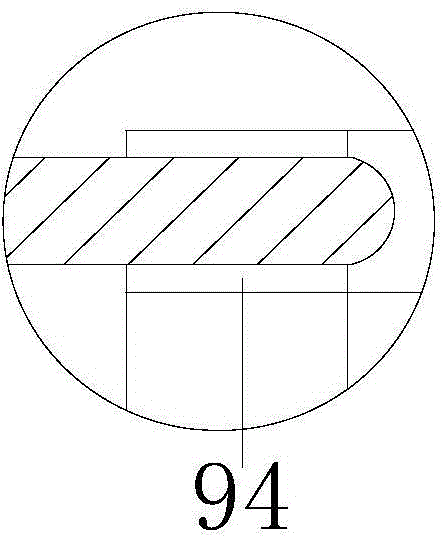

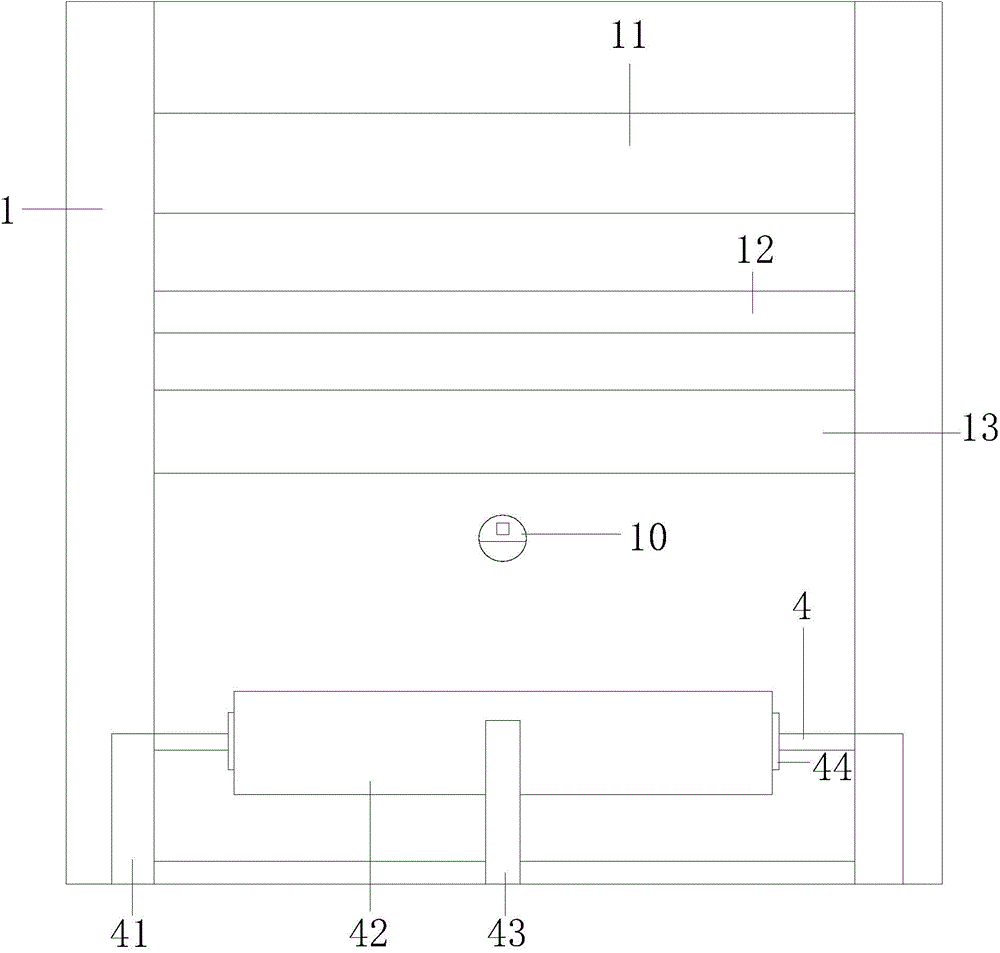

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a multifunctional cloth inspection machine of the present invention, comprising a frame 1, an unwinding device 4, and a roll changing device 9, the frame 1 is equipped with a cloth drop board 2, a smoothing adjustment device 5, a cutting device 7, The tension adjusting device 8 is combined with the cloth guide roller, a lampshade 3 is arranged in front of the cloth drop plate 2, a lamp tube 31 is installed under the lamp shade 3, a camera 32 is installed between the cloth drop plate 2 and the lampshade 3, The cutting device 7 is located in front of the cloth doffing plate 2, the yarn separating roller 6 is arranged under the tension regulating device 8, the doffing roller 11 is installed on the top rear side of the frame, and the unwinding device 4 is located at the rear of the frame 1, the roll changing device 9 is located in front of the frame 1, the unwinding device 4 includes a cloth roll frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com