Combined type oscillation floater wave energy power generation device

A power generation device and combined technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve problems such as failure of hydraulic transmission mechanism, easy displacement of piston rod, unstable output power, etc., and achieve fewer moving parts , Superior follow-up performance and stable output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

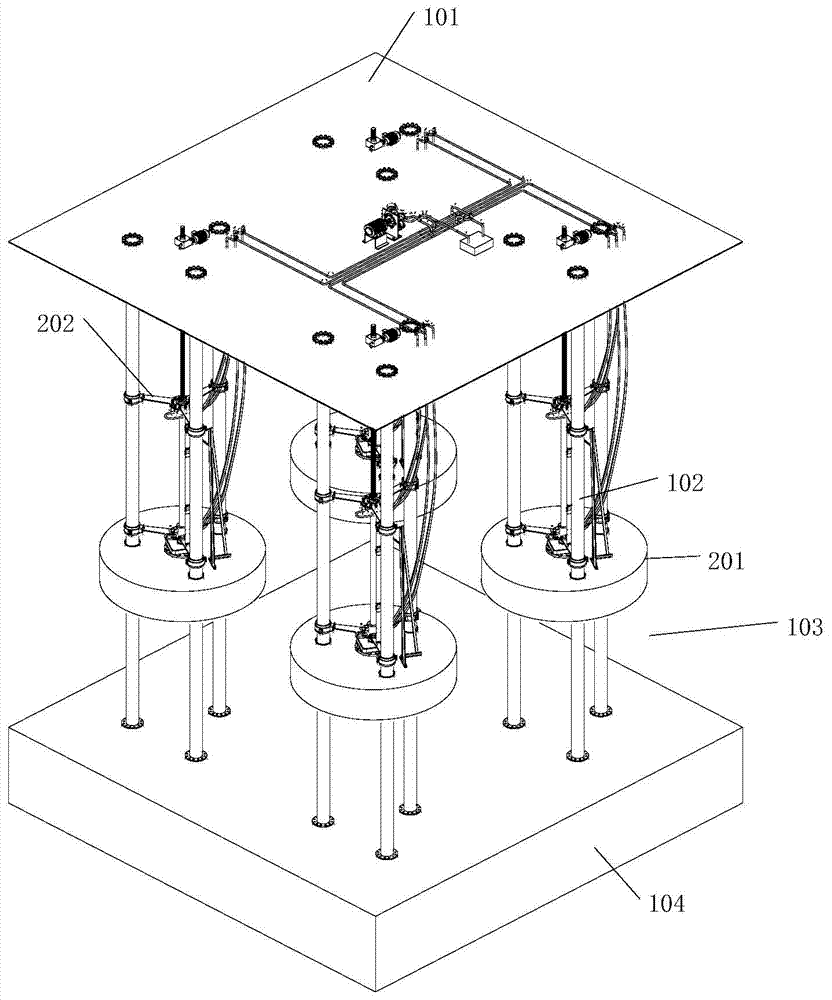

[0026] like Figure 1-Figure 5 Shown: The invention includes power generation systems and stationary systems.

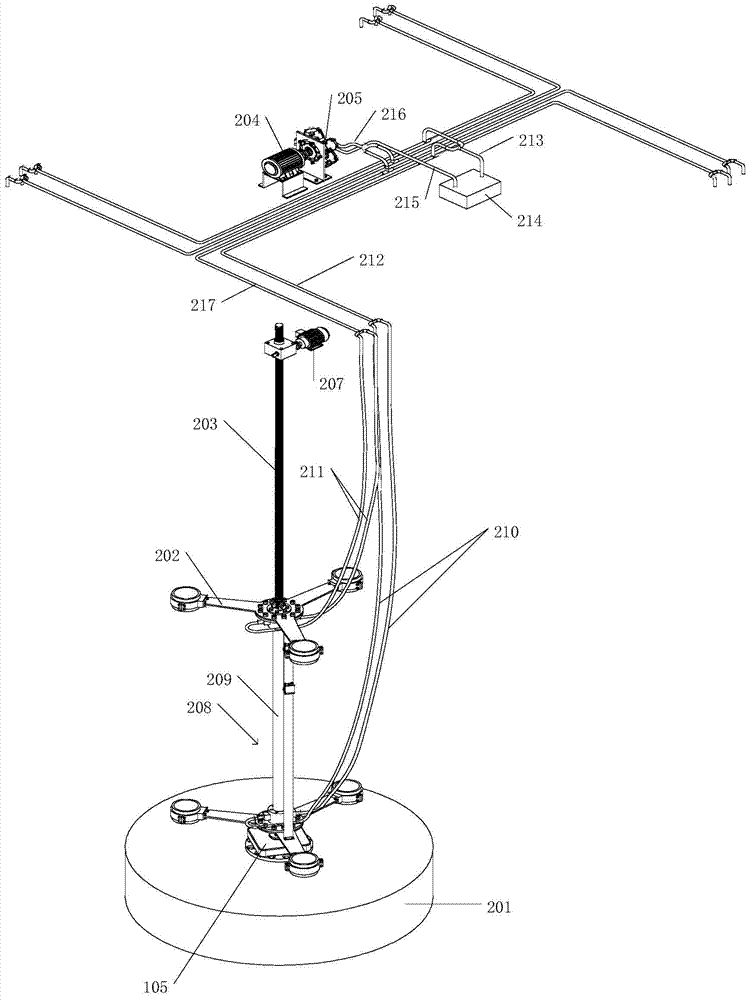

[0027] Wherein, the fixing system includes a submersible buoyant body 104 and a fixed frame 103 , the fixed frame 103 is fixedly connected to the top of the submerged buoyant body 104 , and a working platform 101 is arranged on the top of the fixed frame 103 . The power generation system includes a float 201 , an energy conversion device and a generator 204 . The float 201 is arranged on the four corners of the fixed frame 103. Each corner of the fixed frame 103 is provided with three guide rods 102 which are movably connected with the float 201. The float 201 is set on the guide rod 102 and moves up and down along the guide rod 102. The three guide rods 102 are positive Triangular arrangement. The energy conversion device includes a hydraulic motor 205 and four sets of identical hydraulic transmission mechanisms respectively arranged between the three guide rods 1...

Embodiment 2

[0034] Except following difference, other is with embodiment 1.

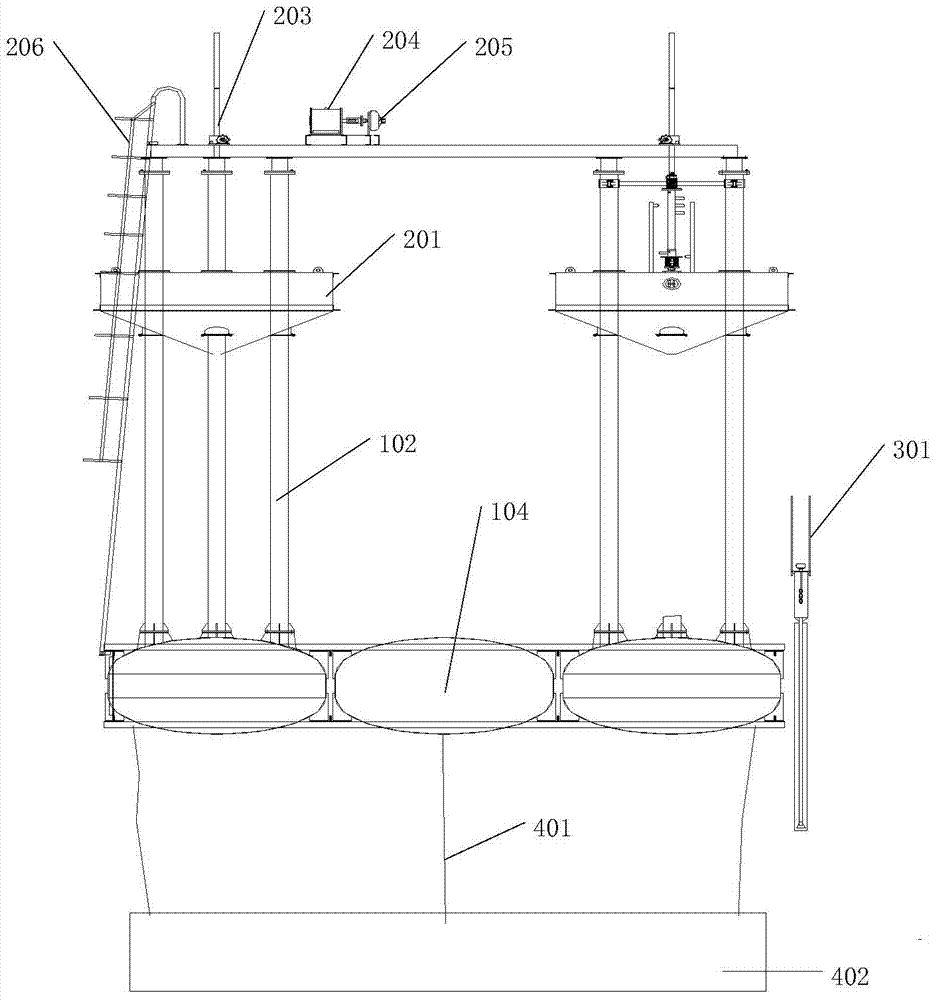

[0035] like figure 2 and Figure 4 As shown, the present invention includes a tidal level monitoring and self-adaptive system, the system includes a tide well 301 and a screw jack 203, the tide well 301 is fixedly connected with the tripod 202 of the hydraulic cylinder 208 through a support 302, and the screw jack 203 is connected to the hydraulic cylinder 208. Cylinder 208 is fixedly connected, and controls hydraulic cylinder 208 to lift. A liquid level switch 303 is provided in the tide well 301 , and the liquid level switch 303 is electrically connected to the starting motor 207 of the screw jack 203 . The starting motor 207 of the screw jack 203 is disposed on the working platform 101 .

Embodiment 3

[0037] Except following difference, other is with embodiment 1.

[0038] like figure 2 As shown, the present invention includes an anchoring system, which includes a counterweight 402 and an anchor cable 401 connected to the submersible body 104 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com