All-fiber high accuracy sensor based on optical fiber multi-mode interference and application thereof

A multi-mode interference and all-optical fiber technology, which is applied in the direction of transmitting sensing components, instruments, liquid level indicators, etc. by using optical devices, can solve the problems of complex manufacturing process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

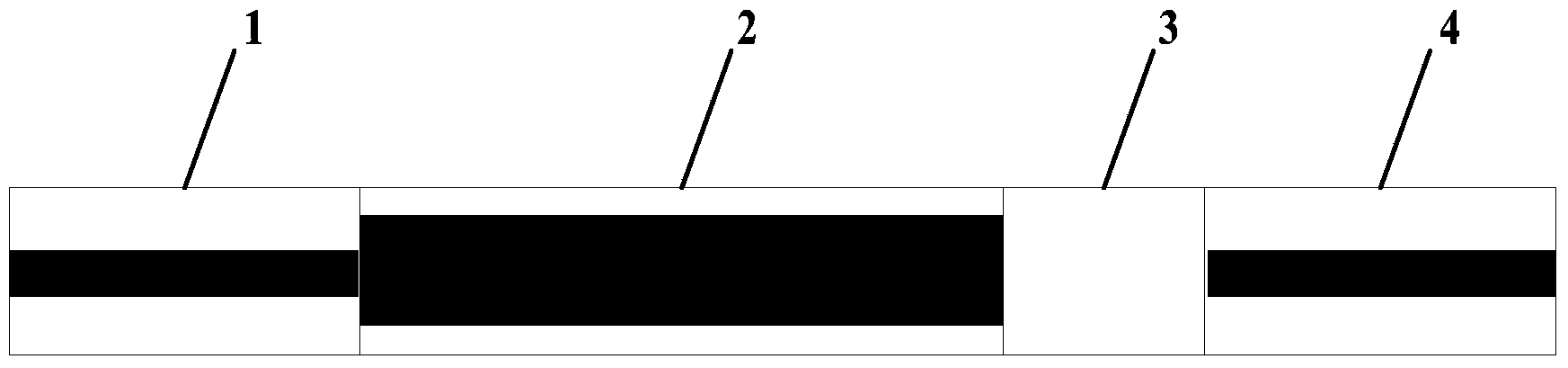

[0012] Such as figure 1 As shown, the all-fiber sensor of the present invention is combined and welded in the order of the first single-mode optical fiber, multi-mode optical fiber, coreless optical fiber and second single-mode optical fiber. The specification of the first single-mode fiber is the same as that of the second single-mode fiber, which is a common single-mode fiber; the multimode fiber is a common multimode fiber. The diameter of the core layer of the single-mode optical fiber is smaller than that of the multi-mode optical fiber; the coreless optical fiber has no core layer structure; the optical fibers have the same cladding diameter, and the automatic fusion splicing mode can be selected when splicing. The length of the multimode optical fiber is 20-150 cm. The length of the coreless optical fiber is n*(1.45-1.47) cm, wherein n is an integer of [1-10]. The length of the coreless optical fiber is optimally 4*(1.45-1.47) cm.

[0013] Select a broad-spectrum lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com