Novel resistive plate chamber detector

A resistive plate chamber and detector technology, applied in the field of radiation detection, can solve the problems of easy opening of gaskets and large dead zone, and achieve the effects of good surface smoothness, high hardness and uniform volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

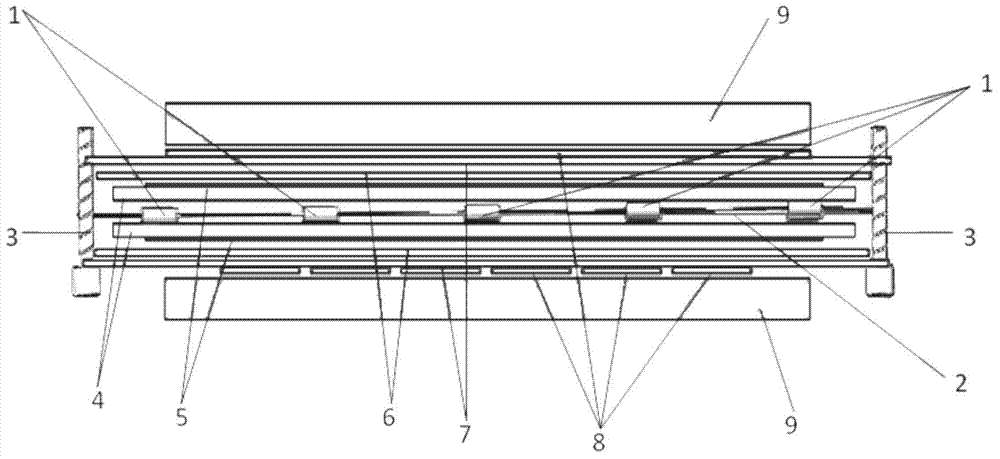

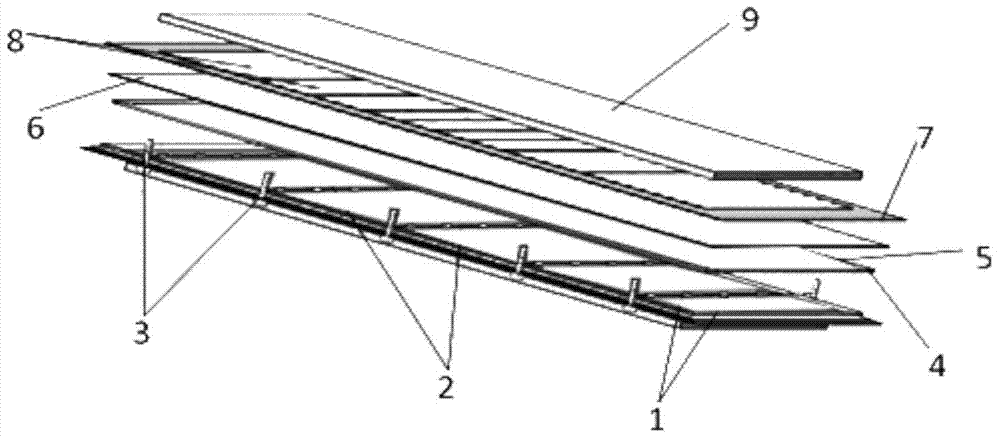

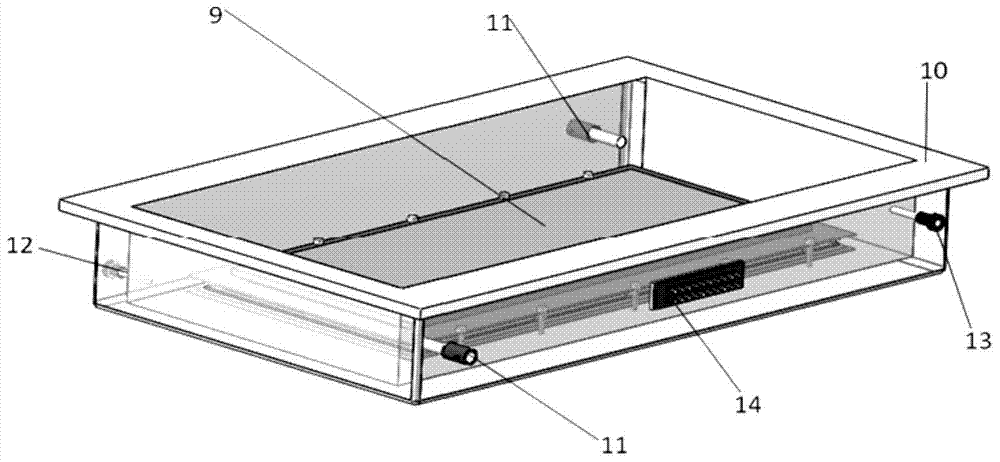

[0022] The present invention provides a novel resistive plate chamber detector. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] The structure of the present invention is as figure 1 As shown, several polyethylene tetrafluoro tubes 1 are arranged side by side, and each polyethylene tetrafluoro tube 1 is divided into multiple sections, which are threaded on a nylon wire 2 in sequence, and adhesive glue is injected into the polyethylene tetrafluoro tube 1 to make It is fixed on the nylon thread 2. The diameter of the polyethylene tetrafluoro tube 1 is 2 mm, the distance between each polyethylene tetrafluoro tube is 80-100 mm, and the length of each segment of the polyethylene tetrafluoro tube is 5-12 mm. The polyethylene tetrafluoro tube 1 is used as the sealing gasket of the resistive plate chamber detector, sandwiched between two pieces of float glass 4, and the outer sides of the two pieces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com