Interdigital back contact solar cell module and manufacturing method thereof

A solar cell module, finger-to-back contact technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of rising cost of solar cell modules, production waste of module reliability, lack of market competitiveness, etc., to simplify operation. , Beautify the appearance, reduce the effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

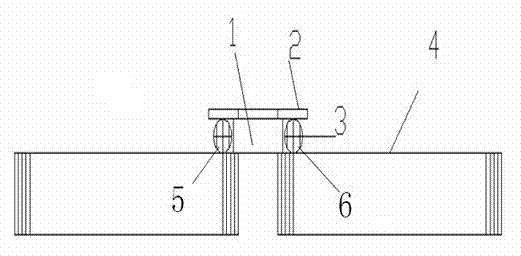

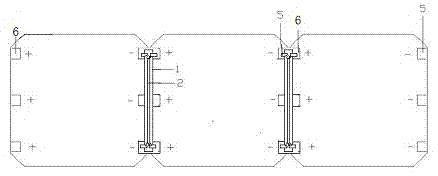

[0031] Example: such as figure 1 , figure 2 As shown, an interdigitated back-contact solar cell assembly includes an insulating adhesive film 1, a conductive tape 2, a conductive adhesive 3, an interdigitated back-contact solar cell sheet 4, an interdigitated back-contact solar cell negative electrode 5, and an interdigitated back contact solar cell module. Contact the positive electrode 6 of the solar cell sheet, and the two interdigitated back contact solar cell sheets 4 are bonded through the insulating adhesive film 1 for pre-fixing; It is connected to the conductive glue 3 coated on the positive electrode 6 of the interdigitated back-contact solar cell sheet and the negative electrode 5 of the interdigitated back-contact solar cell sheet; the insulating adhesive film 1 is a white high A reflective insulating adhesive film 1, the insulating adhesive film 1 has a reflectivity greater than 80%; the length of the insulating adhesive film 1 is 80-200mm, and the width is 4-20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com