Compounded rubber overall-diaphragm filter plate

A membrane filter plate and compound rubber technology, applied in the field of filter presses, can solve the problems of easy deformation and damage of skeleton and filter plate, low yield of filter plate welding, and high comprehensive maintenance cost of filter plate, so as to achieve unobstructed and comprehensive water channels. Low maintenance cost and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

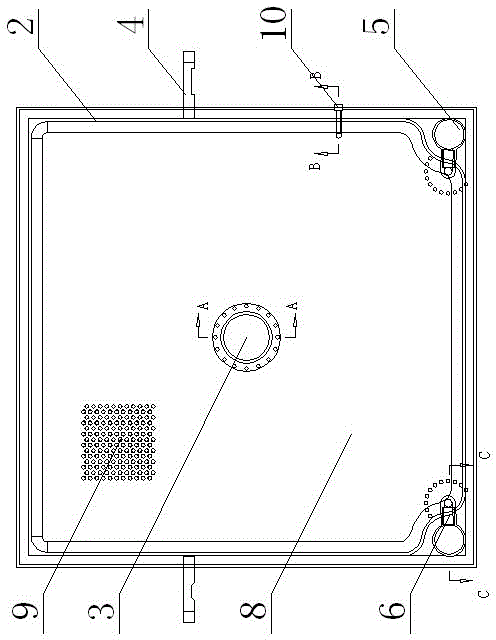

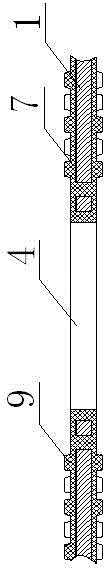

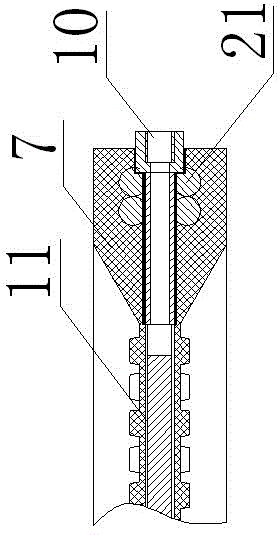

[0018] As shown in the figure, a composite rubber integral diaphragm filter plate includes a filter plate 1 made of stainless steel, a feed hole 3 is provided in the center of the filter plate, and round pipes 21 are welded at the edges of the front and rear sides of the filter plate. The formed filter frame 2 is provided with handles 4 on both sides of the filter frame 2, and the outer surface of the filter frame 2 and the filter plate 1 is covered with a diaphragm 7, and the diaphragm 7 is a vulcanized rubber diaphragm, and the edge of the diaphragm 7 is connected to the The filter frame 2 is sealed and glued, and the center of the diaphragm 7 is sealed and glued to the inlet of the filter plate. The front and rear sides of the diaphragm 1 and the filter plate 1 respectively form a closed cavity 11 in the middle and around the periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com