Roller balance control method of planisher

A balance control and tempering machine technology, applied in the direction of rolling force/roll gap control, etc., can solve problems such as jumping, unleveling, excessive roll gap deviation, etc., to reduce frequent adjustments, reduce roll gap deviation, Guarantee the effect of synchronous response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

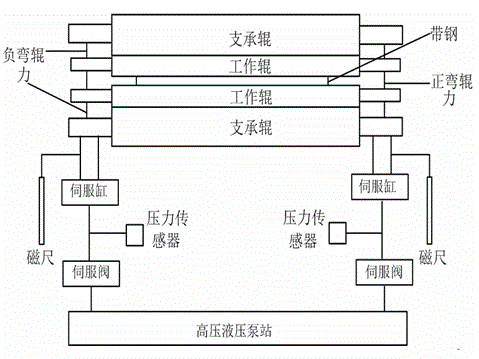

[0023] like figure 1 Shown is a structural schematic diagram of a skin pass mill, including hydraulic servo system control. The hydraulic servo system includes a high-pressure hydraulic pump station, two push-up servo hydraulic cylinders, two servo valves, a position sensor, a pressure sensor, and an accumulator Assembling and connecting pipe fittings, what adopted in the present embodiment of the position sensor are two magnetic rulers. The lower backup roller is connected with the servo hydraulic cylinder, which drives its transmission. The servo hydraulic cylinder is respectively connected to the working side and the transmission side of the lower backup rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com