Preparation method of high-strength high-toughness bionic-function surface wear resistance composite material

A technology of composite materials and bionic functions, which is applied in the field of processing and preparation of bionic wear-resistant composite materials, can solve the problems of high production cost, small scope of application, complex processing technology, etc., to save production costs, improve processing efficiency, and simplify processing steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of biomimetic wear-resistant composite material containing 90wt.% TiC ceramics in hard unit body

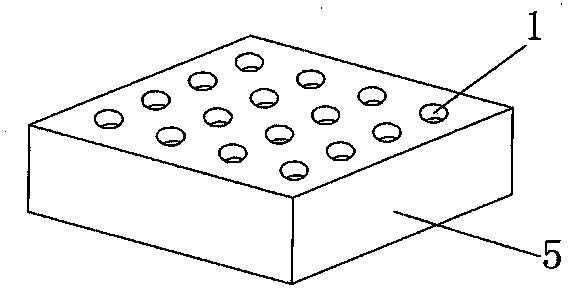

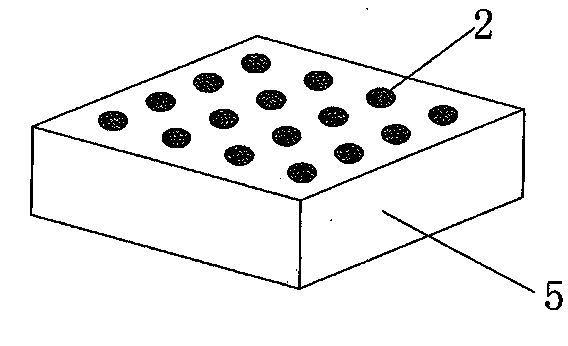

[0034] From the raw powder of the hard unit body, get Al powder (average particle size less than 70 μm, purity 99.0%), Ti powder (average particle size less than 70 μm, purity 99.0%) and C powder (average particle size less than 40 μm, purity 99.0%) ). The above-mentioned three kinds of powders are mixed with the content of Al being 10wt.%, the content of Ti powder and C powder being 90wt.%, and the molar ratio of Ti powder and C powder is 1:1. A circular pit 1 with a depth of 5 mm, a diameter of 5 mm, and a center distance of 15 mm is processed on the carbon steel substrate 5, such as figure 1 shown. After the raw powder of the hard unit body is fully mixed and uniform, it is placed in the uniformly distributed circular pits 1 and compacted at a compaction rate of 60% of its theoretical density. Put the carbon steel base body with the hard unit body materia...

Embodiment 2

[0036]Preparation of biomimetic wear-resistant composite material containing 70wt.% TiC ceramics in hard unit body

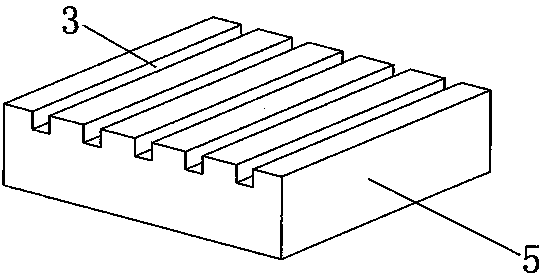

[0037] From the raw powder of the hard unit body, get Al powder (average particle size less than 65 μm, purity 99.0%), Ti powder (average particle size less than 65 μm, purity 99.0%), C powder (average particle size less than 35 μm, purity 99.0%) ). The above-mentioned three kinds of powders have an Al content of 30wt.%, and the combined content of Ti powder and C powder is 70wt.%, and the Ti powder and C powder are mixed evenly in a molar ratio of 1:1. On the carbon steel substrate 5, the depth is 5 mm, the width is 5 mm, and the stripe-shaped pits 3 with a spacing of 10 mm are processed, such as image 3 shown. After the raw powder of the hard unit body is fully mixed and uniform, it is placed in the uniformly distributed stripe-shaped pits 3 and compacted according to a compaction rate of 60% of its theoretical density. Put the carbon steel substrate 5 loa...

Embodiment 3

[0039] Preparation of biomimetic wear-resistant composite material containing 50wt.% TiC ceramics in hard unit body

[0040] From the raw powder of the hard unit body, get Al powder (average particle size less than 60 μm, purity 99.0%), Ti powder (average particle size less than 60 μm, purity 99.0%), C powder (average particle size less than 35 μm, purity 99.0%) ). The content of the above three powders is 50wt.%, the content of Ti powder and C powder is 50wt.%, and the molar ratio of Ti powder and C powder is 1:1. A circular pit 1 with a depth of 5 mm, a diameter of 7 mm, and a center distance of 17 mm is machined on the carbon steel substrate 5 . After the raw powder of the hard unit body is fully mixed and uniform, it is placed in evenly distributed circular pits and compacted at a compaction rate of 60% of its theoretical density. Put the carbon steel substrate 5 loaded with the hard unit body material into the vacuum heating device, pass in argon gas after completing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com