Drive advancing train

A technology of trains and mine roads, which is applied in the field of mine road trains, which can solve the problems of damage to equipment and personnel, potential safety hazards, easy fall and injury, etc., and achieve the effects of improving efficiency, convenient transportation and assembly, and easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

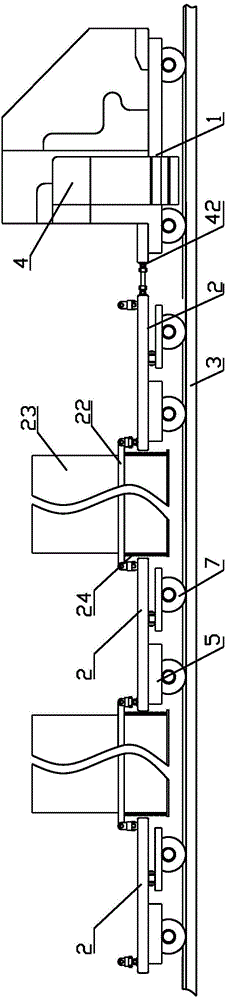

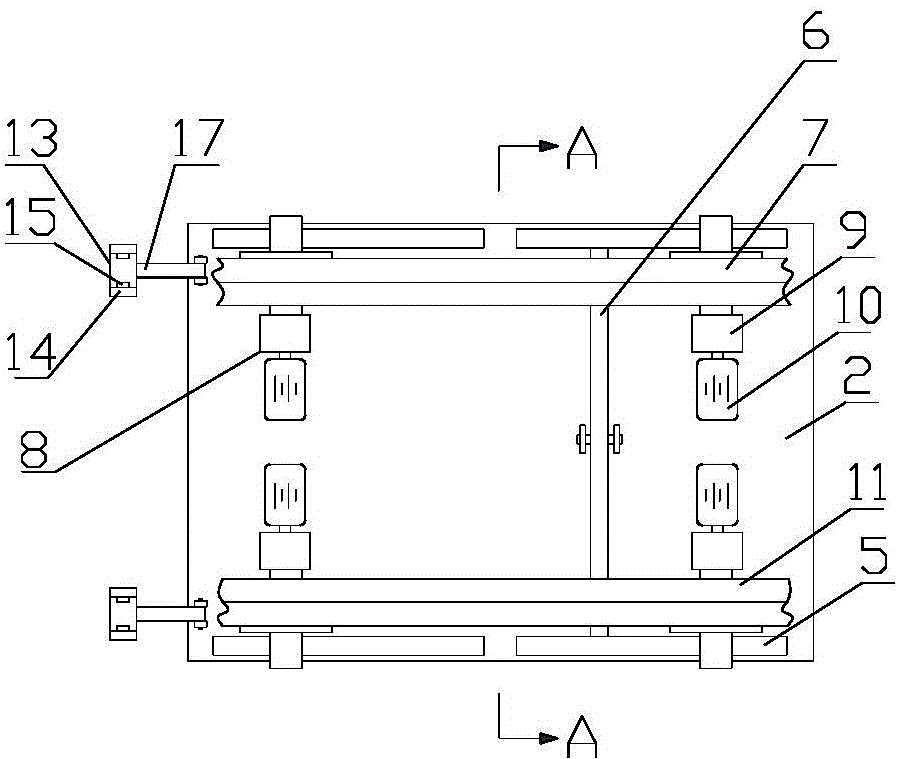

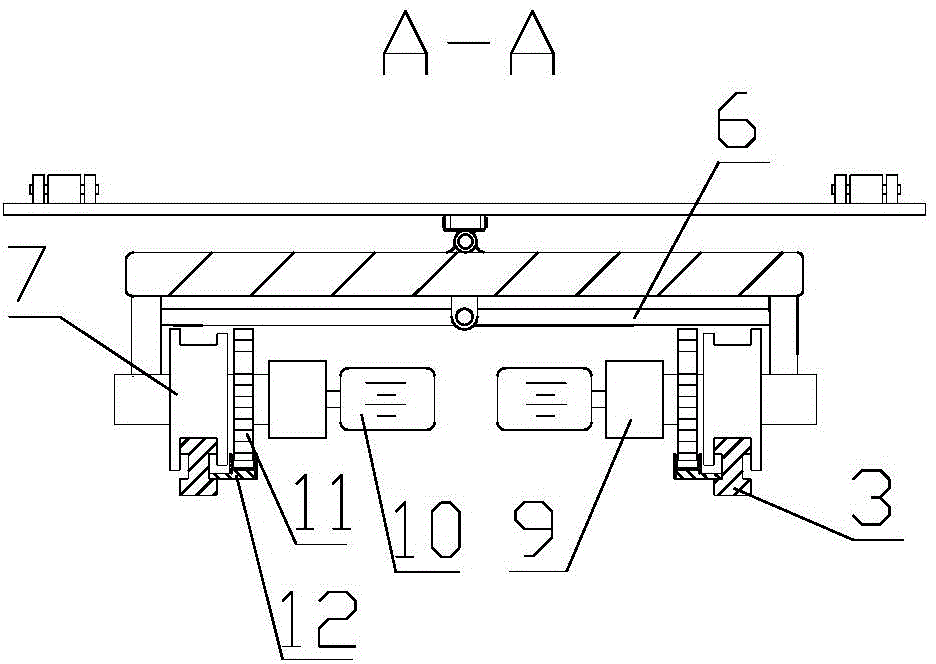

[0030] Embodiment 1: as figure 1 As shown, the train traveling in the mine road includes a train head 1 and three train chassis 2, the train head 1 and the adjacent train chassis 2 are connected by universal joints, and travel along the track 3, and a control system is provided in the train head 1. Switch 4; as in figure 2 As shown, a traveling wheel fixing plate 5 is fixedly arranged on both sides of the bottom of one end of each train chassis 2, and a traveling wheel regulating arm 6 is movably hinged at the bottom center of the other end, and a traveling wheel regulating arm 6 is fixedly provided at both ends of the advancing wheel regulating arm 6. Wheel fixed plate 5, is provided with traveling wheel 7 and traveling wheel driver 8 on each traveling wheel fixed plate 5, and traveling wheel driver 8 comprises reducer 9 and explosion-proof motor 10, and traveling wheel 7 is connected with explosion-proof motor 10 by reducer 9 , the traveling wheel 7 is driven by the explos...

Embodiment 2

[0031] Embodiment 2: as Figure 8 As shown, the mine road train includes a train head 1 and three train chassis 2, the train head 1 and the adjacent train chassis 2 are connected by universal joints, and travel along the track 3, and a control system is provided in the train head 1. Switch 4; Its overall structure is identical with embodiment 1, and difference is that it also comprises track installation vehicle 25, and track installation vehicle 25 comprises track installation chassis 28, is provided with track installation crane 29 on track installation chassis 28, and track installation The chassis 28 is connected to the front end of the train locomotive 1 through a cardan shaft; the traveling wheel drive 8 includes a pump station 26 and a hydraulic motor 27. Switch 4 is connected as Figure 9 As shown, the travel wheel 7 is driven by a hydraulic motor 27 .

Embodiment 3

[0032] Embodiment 3: as Figure 10 As shown, the mine road train includes a train locomotive 1, three train chassis 2, and a rail installation car 25. Its overall structure is the same as that of Embodiment 2, except that it also includes a rail row storage car 30 and a cable support car 31, such as Figure 11 As shown, the rail storage car 30 includes a track retractable chassis 32 and a bridge frame 33, a bridge lifting column 34 is arranged on the track retractable chassis 32, and a cable tray 35 is arranged on the top of the bridge lifting column 34, and one end of the cable tray 35 passes through the ten thousand The joint is hinged with one end of the bridge frame 33; the other end of the bridge frame 33 is connected with the self-moving tail of the belt conveyor through a universal joint, or connected with the self-moving tail of the scraper machine through a universal joint, or connected with the self-moving tail at the end of the roadway. The hydraulic support is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com