Composite type marine noise reduction structure

A composite, marine technology, applied in the direction of hull, hull paneling, hull components, etc., can solve problems such as difficulty in meeting IMO, achieve vibration and noise reduction, good sound insulation, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

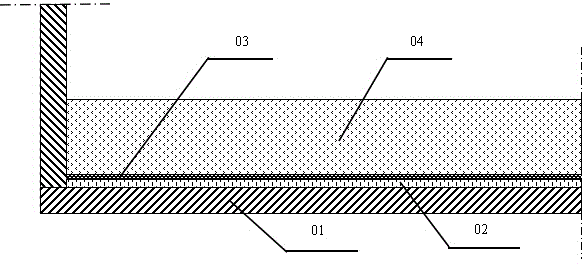

[0016] Such as figure 1 As shown, a composite marine noise reduction structure, on a horizontal steel deck 01, a damping layer 02, a steel sheet or steel plate 03 and a coating layer 04 are sequentially laid.

[0017] Steel deck 01 has good hardness and high strength. The polyurea elastomer layer is directly laid on the steel deck 01 as the damping layer 02, and the flame-retardant spray polyurea elastic waterproof coating of the commercially available brand "Yuhong" SPUA-352 is selected, with a thickness of 4mm. After the polyurea elastomer is fully dried and cured, the damping adhesive is brushed, and the steel sheet or steel plate is bonded to the damping layer through the damping adhesive to obtain the steel sheet or steel plate layer 03. The damping adhesive used is a graft copolymer of methyl methacrylate (MMA) and chloroprene rubber (CR). When coating steel sheets or steel plates, the glue is applied three times, and the thickness of the glue layer is 0.15mm. Finally,...

Embodiment 2

[0020] The composite marine noise reduction structure is the same as that of Example 1, except that the polyurea elastomer layer is directly laid on the steel deck 01 as the damping layer 02, and the commercially available flame-retardant "Yuhong" SPUA-352 is selected. Type spray polyurea elastic waterproof coating with a thickness of 5mm. Graft copolymer of methyl methacrylate (MMA) and chloroprene rubber (CR), when coating steel sheets or steel plates, apply glue 3 times, and the thickness of the glue layer is 0.1mm. Lay the dressing layer 04, choose the ultra-light dressing produced by Taicang Lanyan Deck Dressing Coating Co., Ltd., and the thickness of this layer is 40mm.

[0021] With reference to the GB / T19889.10-2006 standard, the composite marine noise-reducing structure prepared was tested, and the sound insulation weighted index was 45dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com